Array type ultra-narrow linewidth laser

An ultra-narrow linewidth, array-type technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of inconsistent compression, complex structure, high cost, etc., and achieve the effect of reducing temperature and protecting laser emitting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

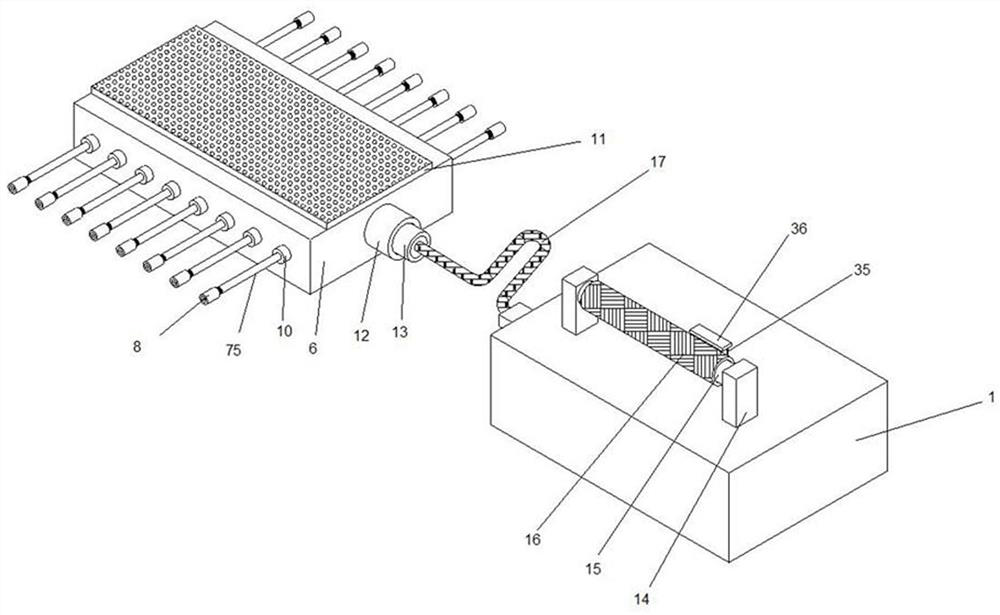

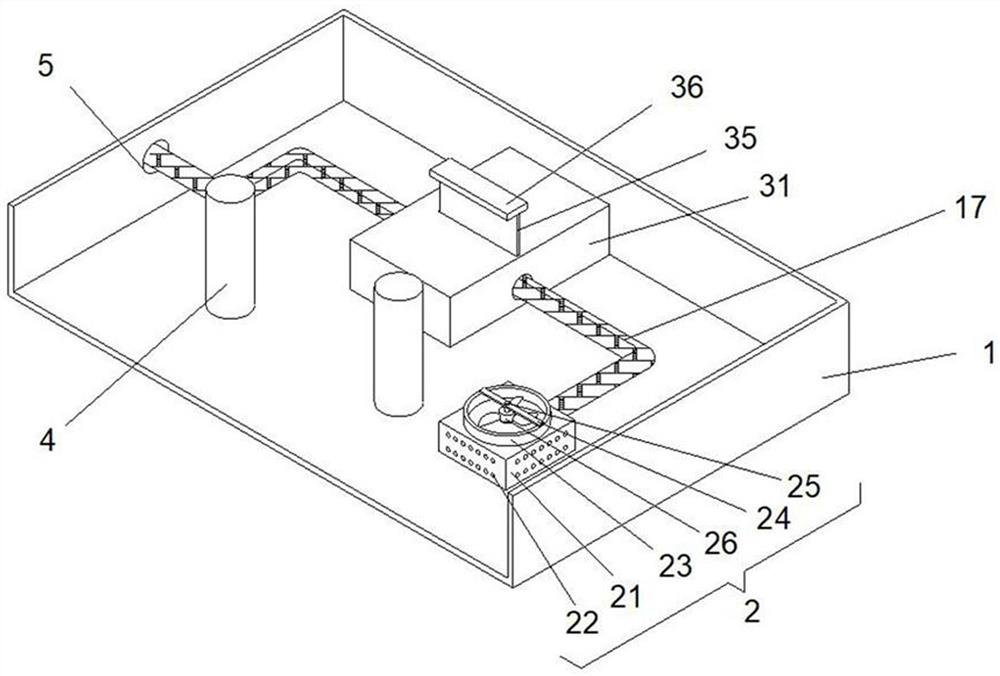

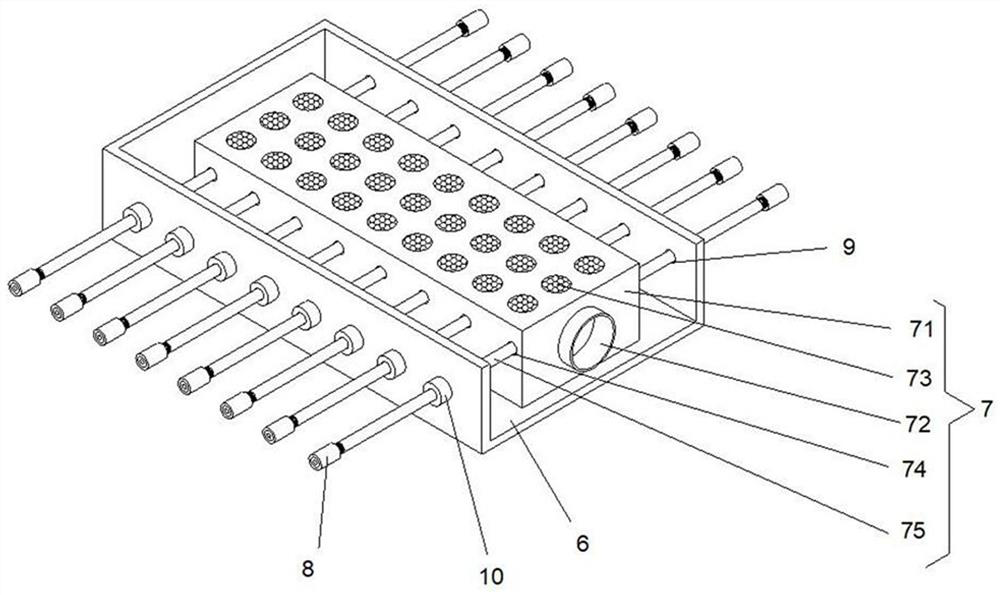

[0029] Embodiment: array type ultra-narrow linewidth laser, such as Figure 1-Figure 5As shown, it includes a first housing 1 and a second housing 6, the first housing 1 is a hollow rectangular box, the second housing 6 is a hollow rectangular box, and the first housing 1 is fixedly installed with a laser Generating device 2, laser generating device 2 comprises chassis 21, and described chassis 21 is the rectangular casing of top opening, and the front, rear, left and right sides of chassis 21 are all provided with multiple groups of ventilation holes 22, and described ventilation holes 22 are circular holes, The top of the cabinet 21 is vertically fixed with a surrounding frame 23, the surrounding frame 23 is a circular ring, and the top middle position of the surrounding frame 23 is fixedly equipped with a connecting rod 24, and the connecting rod 24 is a rectangular long plate, and the connecting rod The length of 24 is identical with the diameter of surrounding frame 23, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com