Integrated electric drive system and electric vehicle

An electric drive system, integrated technology, applied in the direction of motor vehicles, vehicle parts, electric power devices, etc., can solve the problems affecting the layout and heat dissipation of electronic devices, restrictions, space waste, etc., to achieve improved heat dissipation capacity, compact components, and reduce The effect of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

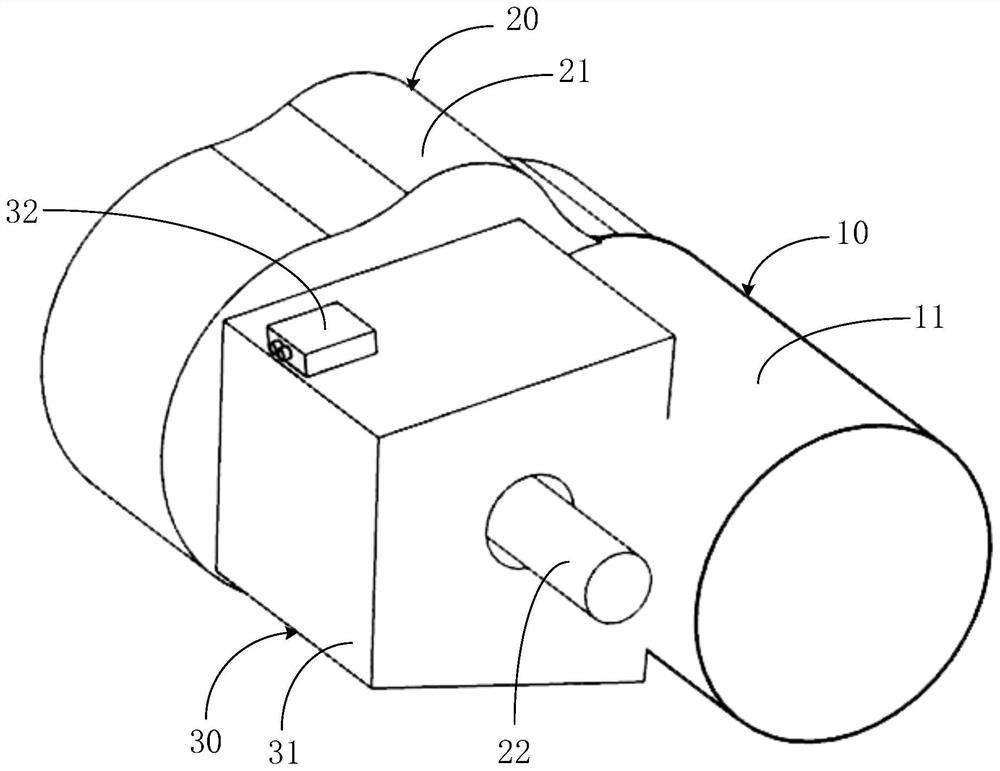

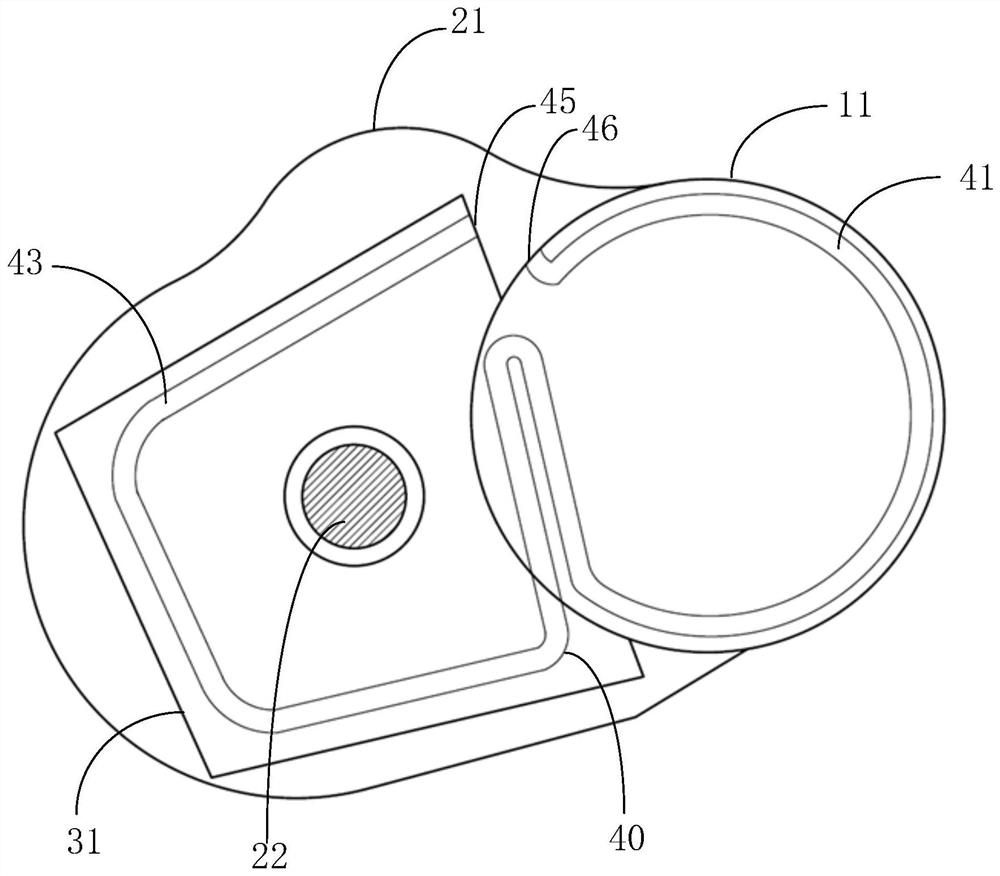

[0023] The preferred embodiments of the present application are described in detail below with reference to examples. In the embodiments of the present application, the application is described by taking an integrated electric drive system for an electric vehicle as an example. However, those skilled in the art should understand that these exemplary embodiments do not imply any limitation to the present application. In addition, the features in the embodiments of the present application may be combined with each other under the condition of no conflict. In different drawings, the same or similar components are denoted by the same reference numerals, and other components are omitted for brevity, but this does not mean that the integrated electric drive system of the present application cannot include other components. It should be understood that the dimensions, proportions and numbers of components in the drawings are not intended to limit the application.

[0024] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com