Optical element and optical module

A technology for optical components and optical modules, applied in the field of optics, can solve the problems of assembly and adjustment deviation, high economic cost, and unsuccinct optical structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

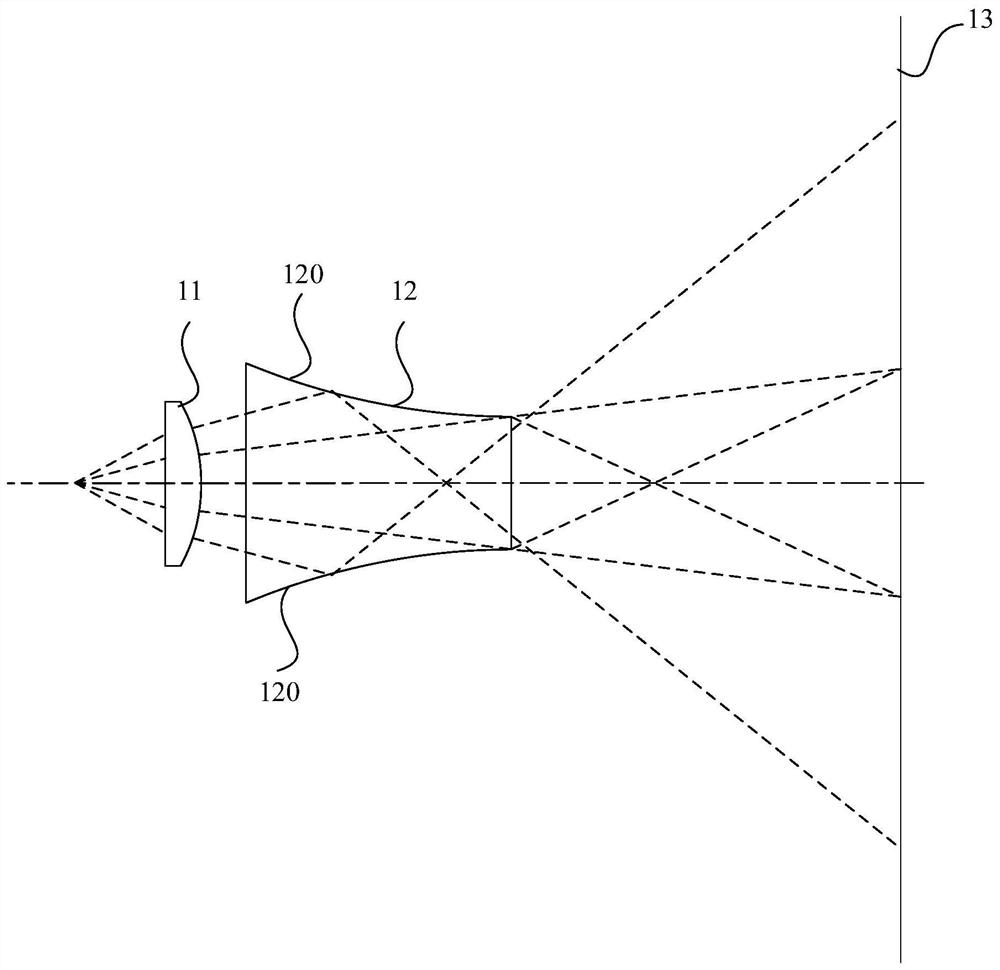

[0071] Such as figure 1 As shown, it includes semiconductor laser light source, compression mirror 11 or beam expander mirror and the first reflective surface 120 is the optical element 12 (optical waveguide) of concave arc, and the exit end is a small end (two first reflective surfaces 120 surface type is a reverse To a paraboloid or a hyperboloid, the surface type is corrected into an aspherical surface through a high-order term coefficient).

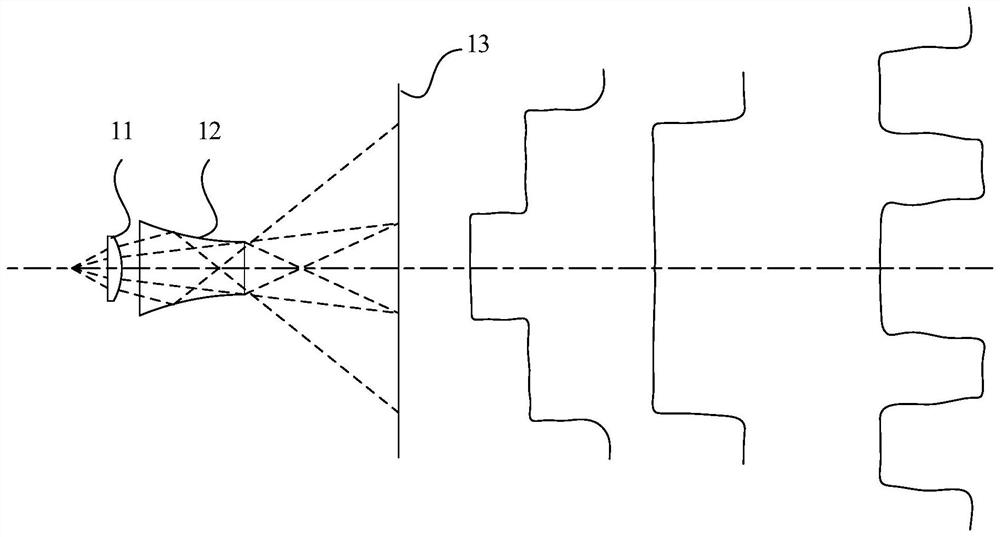

[0072] The laser beam emitted by the semiconductor laser passes through the slow axis compression mirror 11 (only the spot size is compressed), and exits into the side arc-shaped optical waveguide. A reflective surface 120 arc surface type total reflection or reflective exit, forming figure 2 Spot energy distribution shown. The arc surface type is a reverse paraboloid or a hyperboloid or a high-order aspheric surface of both basic surface types. The outgoing light beams on both sides form a certain angle with the middle light beam...

Embodiment 2

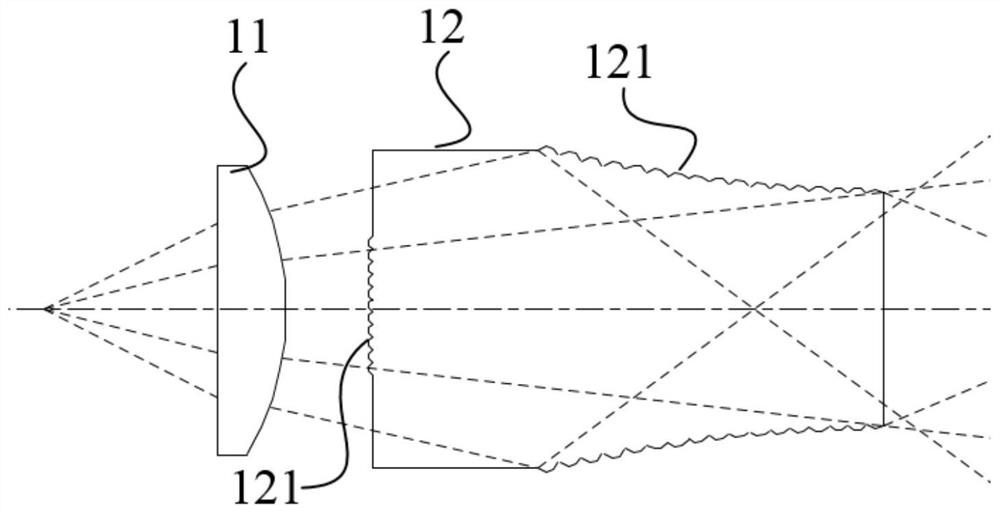

[0074] The difference between this embodiment and the first embodiment is that the first reflective surface 120 is Figure 5 In the convex arc shape shown, the surface type of the first reflecting surface 120 is a forward parabola or a hyperboloid, and the surface type is corrected to an aspheric surface through the high-order coefficient, forming Figure 6 Spot energy distribution shown. The arc of the first reflecting surface 120 has Figure 7 The shown microstructure 121, the microstructure 121 is a concave surface, concave to the main optical axis, forming Figure 8 Spot energy distribution shown.

Embodiment 3

[0076] The difference between this embodiment and the first embodiment is that the first reflective surface 120 is Figure 9 As shown in the convex arc shape, the exit end is a large end, and the surface type of the first reflecting surface 120 is a reverse paraboloid or a hyperboloid, and the surface type is corrected to an aspherical surface through the coefficient of the high-order term, forming Figure 10 Spot energy distribution shown. The arc of the first reflecting surface 120 has Figure 11 As shown in the microstructure 121, the microstructure 121 is a concave surface, concave toward the main optical axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com