High-corrosion-resistance multilayer composite carbon coating of fuel cell bipolar plate

A multi-layer composite and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of high potential corrosion, metal layer oxidation and limited application environment, etc., achieve low preparation cost and avoid the decline of coating conductivity , the effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

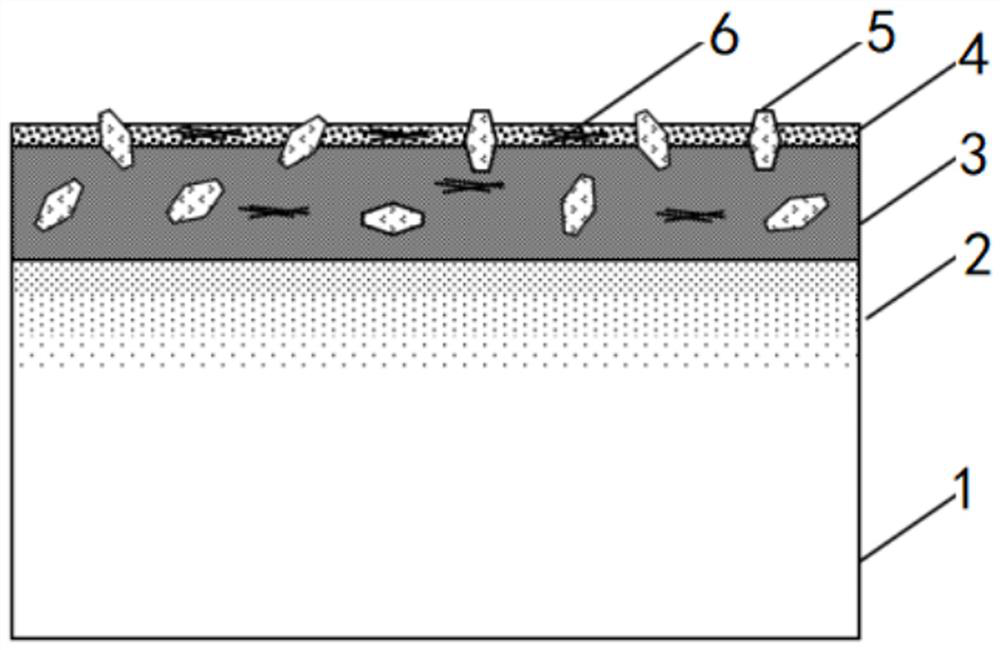

[0028] A multi-layer composite carbon coating for highly corrosion-resistant fuel cell bipolar plates, the structure of which is as follows figure 1 as shown,

[0029] (1) Carrying out plasma carburizing on the metal substrate 1 of the bipolar plate to generate a diffusion infiltration layer 2 composed of 90% C by mass fraction and 10% SiC by mass fraction;

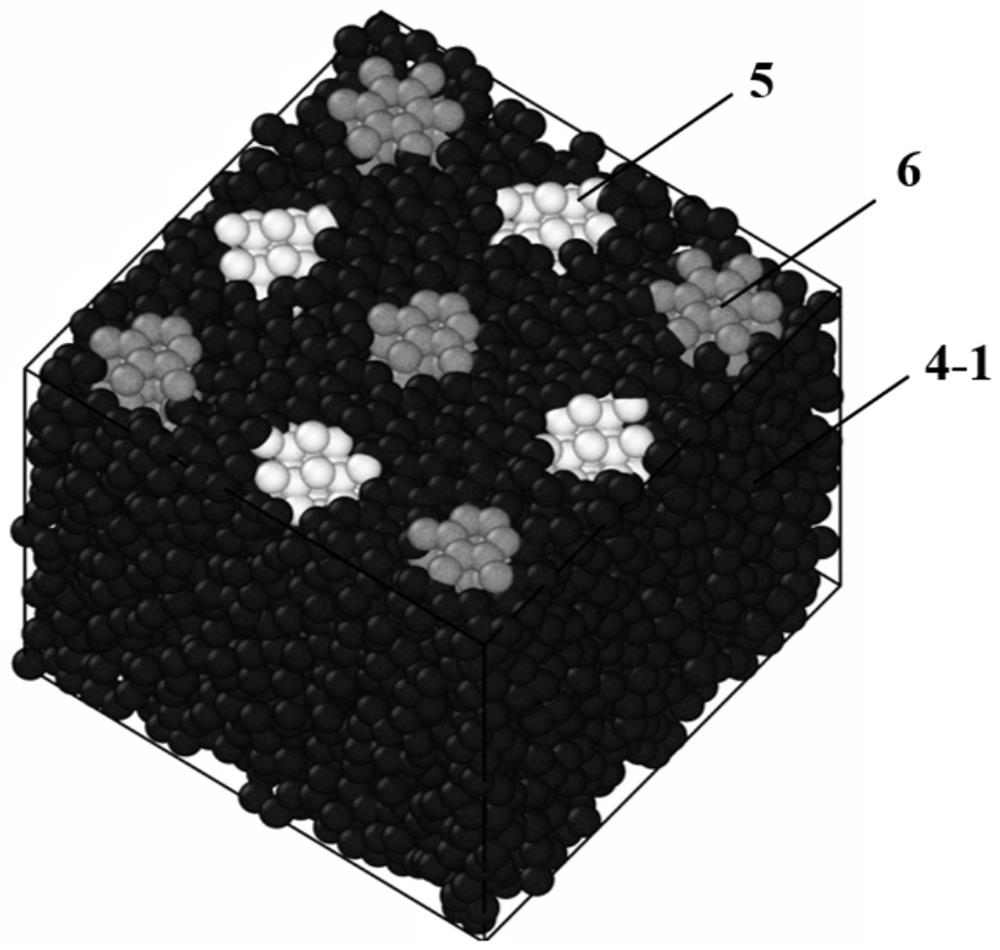

[0030] (2) Then, on the surface of the diffusion and penetration layer 2, a dense corrosion-resistant layer composed of 95% amorphous carbon, 3% hydrogen and 2% oxygen is deposited by plasma-assisted chemical vapor deposition. 3. Diamond particles or diamond-like carbon particles are embedded in or on the surface of the dense corrosion-resistant layer 3, and its coverage on the surface of the dense corrosion-resistant layer 3 is 40%;

[0031] (3) Finally, on the surface of the dense corrosion-resistant layer 3, deposit a layer of C element with a mass fraction of 95%, doped with 2% O and 3% N to form a performance regula...

Embodiment 2

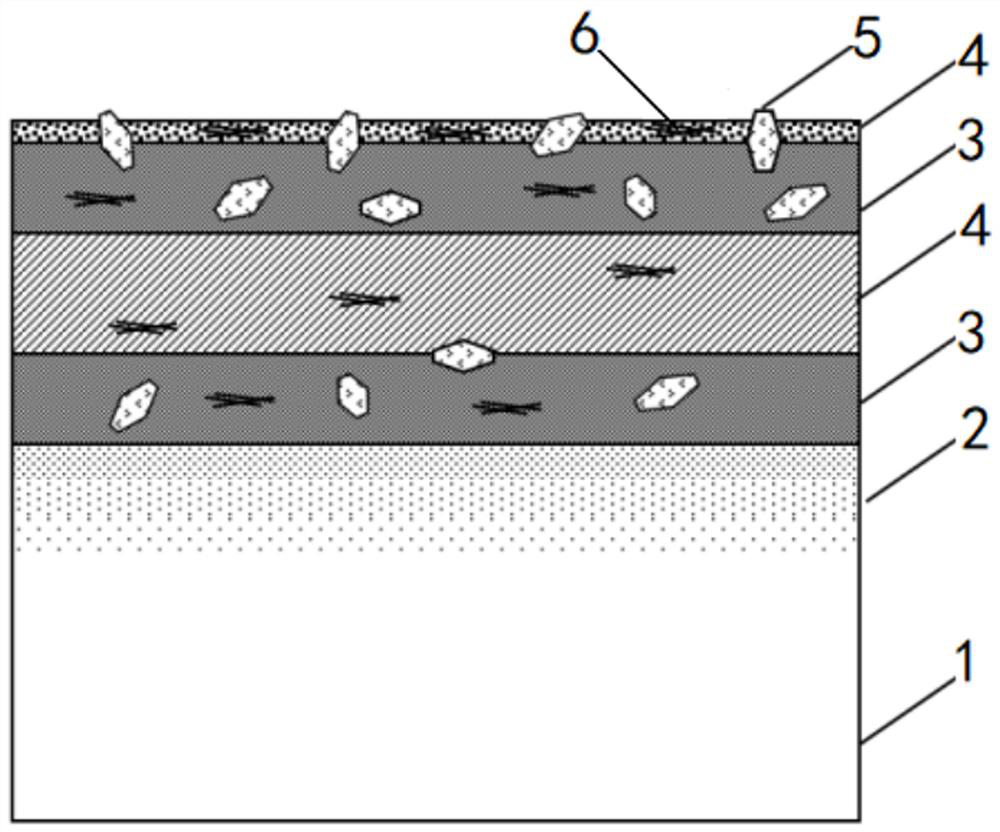

[0033] A multi-layer composite carbon coating for highly corrosion-resistant fuel cell bipolar plates, the structure of which is as follows figure 2 as shown,

[0034](1) Carry out plasma carburizing on bipolar plate metal base material 1 and generate Si by mass fraction 97% C and mass fraction 3% 3 N 4 Diffusion and penetration layer 2 composed of materials;

[0035] (2) Then, on the surface of the diffusion and penetration layer 2, a layer of dense corrosion-resistant material composed of 95% amorphous carbon, 3% hydrogen and 2% oxygen is sequentially deposited by plasma-assisted chemical vapor deposition. Layer 3 and a performance control layer 4 composed of 90% C element doped with 3% Si, 3% O and 4% N; diamonds are embedded in the inner or surface of the dense corrosion-resistant layer 3 Particles or diamond-like carbon particles, whose coverage on the surface of the dense corrosion-resistant layer 3 is 5%;

[0036] (3) A layer of amorphous carbon with a mass fractio...

Embodiment 3

[0039] A multi-layer composite carbon coating for highly corrosion-resistant fuel cell bipolar plates, the structure of which is as follows figure 1 as shown,

[0040] (1) Carrying out plasma carburizing on the metal substrate 1 of the bipolar plate to form a diffusion infiltration layer 2 composed of SiC with a mass fraction of 95% and N materials with a mass fraction of 5%;

[0041] (2) Then, on the surface of the diffusion and penetration layer 2, a dense corrosion-resistant layer composed of 90% amorphous carbon, 7% hydrogen and 3% oxygen is deposited by plasma-assisted chemical vapor deposition. 3; diamond particles or diamond-like carbon particles are embedded inside or on the surface of the dense corrosion-resistant layer 3, and its coverage on the surface of the dense corrosion-resistant layer 3 is 17%; in the dense corrosion-resistant layer 3, the mass fraction is randomly distributed. 4% flake graphite;

[0042] (3) Finally, on the surface of the dense corrosion-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com