A kind of method for preparing jadeite glass-ceramic

A technology for glass-ceramic and jadeite, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as the difficulty of jadeite crystallites, and achieve the effect of reducing the requirements of preparation conditions and the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

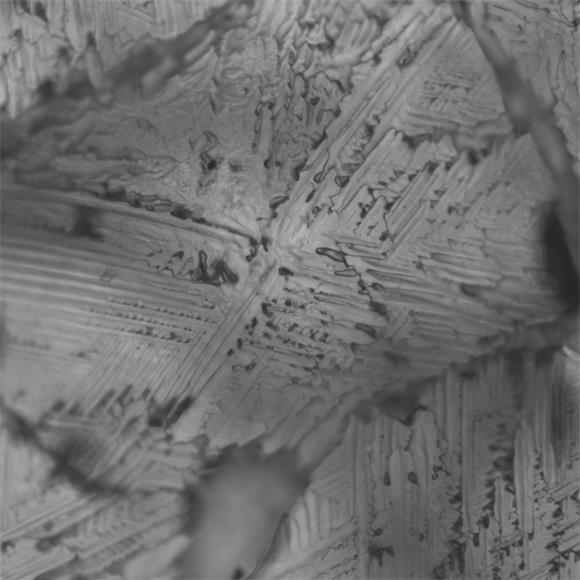

Image

Examples

Embodiment

[0022] With aluminum silicate fiber (model: SYGX-311, the composition mass ratio Al 2 O 3 : SiO 2 =48:50), silicic acid (H 2 SiO 3 ), sodium carbonate (Na 2 CO 3 ) as raw material, according to jade (NaAlSi 2 O 6 The theoretical mass fraction ratio of each element in the molecular formula of ) is weighed, and the following techniques and specific steps are used to synthesize jadeite samples by high temperature and normal pressure solid phase sintering method:

[0023] (1) Preparation of reaction starting materials

[0024] Firstly, the aluminum silicate fiber and silicic acid are crushed and mixed, and then mixed with sodium carbonate solution dissolved in deionized water, stirred to make the mixture fully uniform, and then the mixture is placed in a muffle furnace and kept at 160 °C for 2 hours. Take out, pulverize, grind and briquette the block to complete the preparation of the initial material;

[0025] (2) The first sintering

[0026] The briquetting initial mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com