Preparation method of gabapentin intermediate

A technology for gabapentin and intermediates, which is applied in the field of preparation of gabapentin intermediates, can solve the problems of cumbersome steps, unfavorable industrial production, and expensive raw materials, and achieve the effects of shortened steps, low cost, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

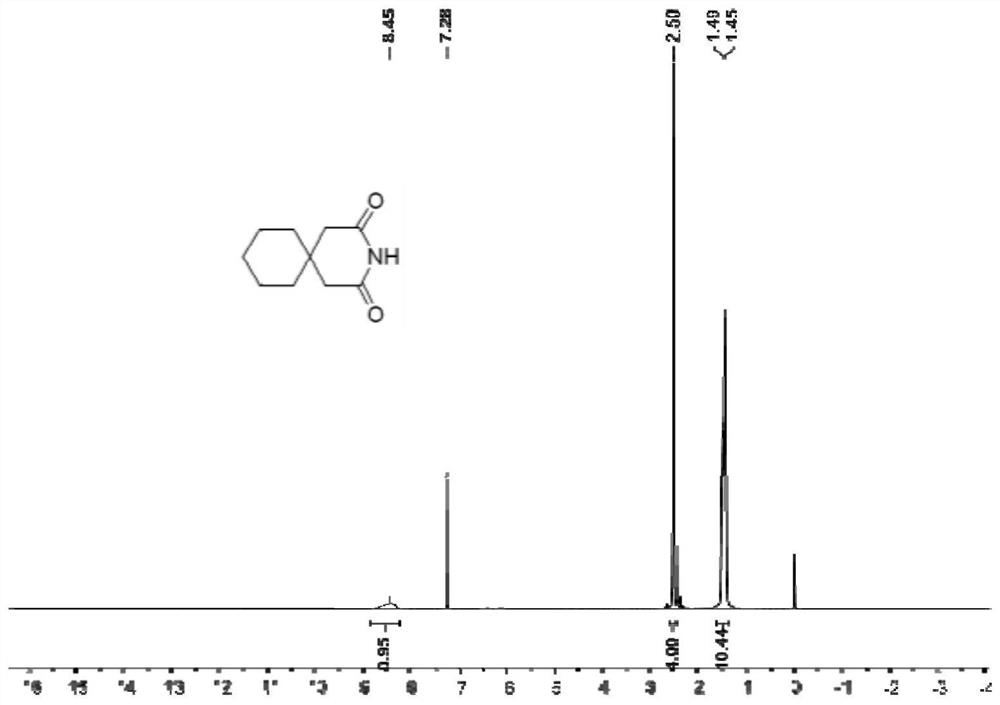

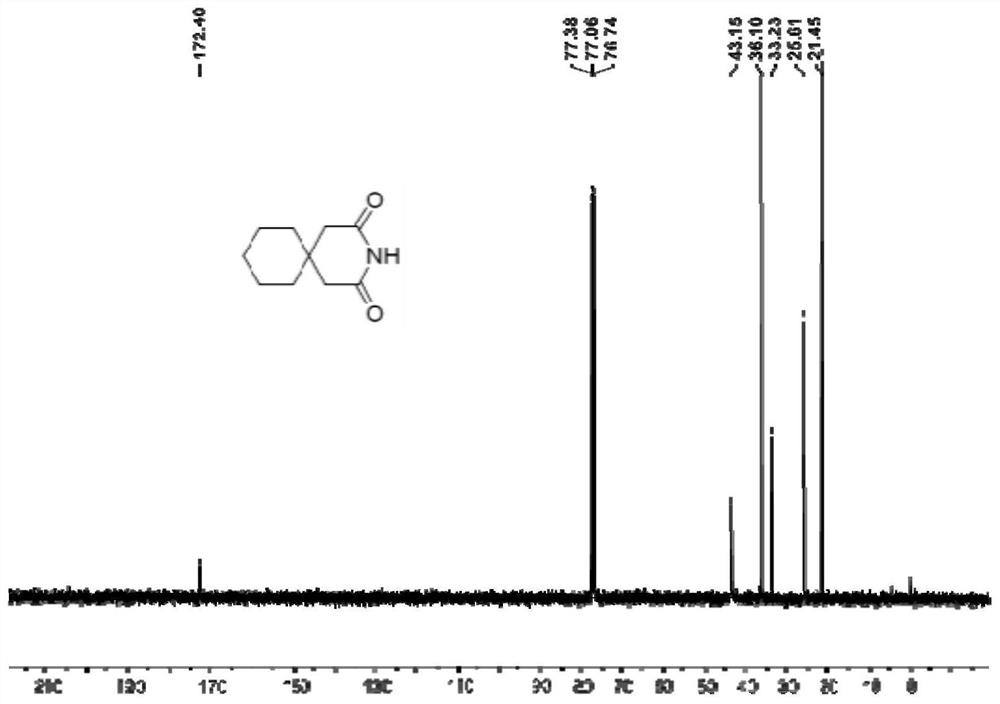

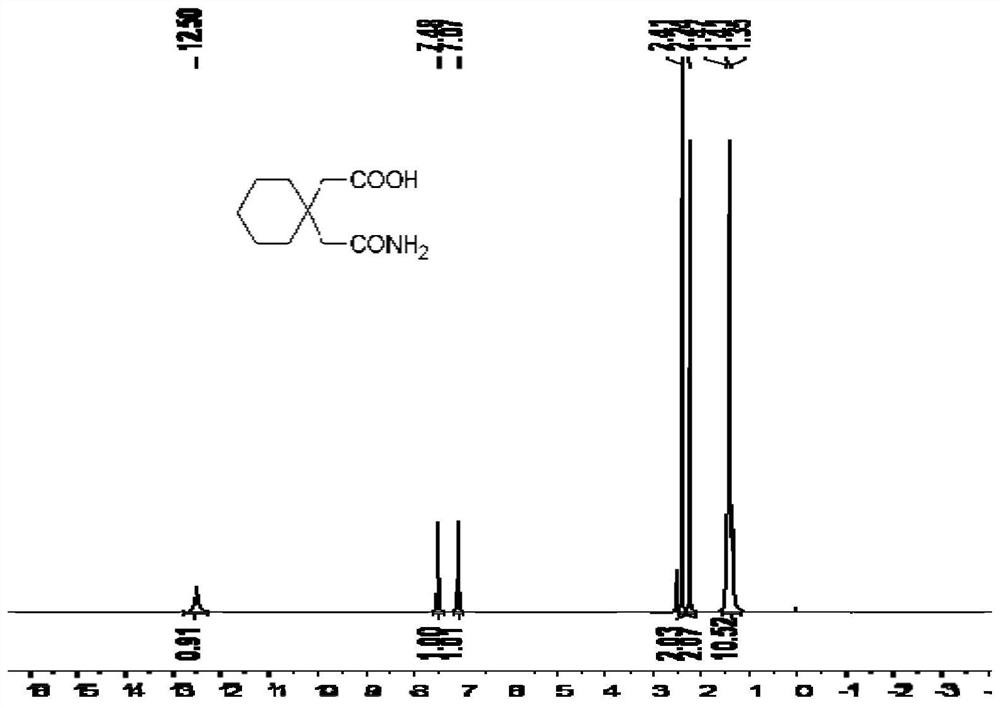

Image

Examples

Embodiment 1

[0076] Embodiment 1 A kind of preparation method of gabapentin intermediate

[0077] Specifically include the following steps:

[0078] (1) Cool down to below 10°C, add 249g of 70% cyanoacetic acid aqueous solution to the lye prepared by water (210g) and sodium hydroxide (90g) and mix to form cyanoacetic acid alkali solution; control the internal temperature to 15°C , slowly drop cyclohexanone (98g) into the cyanoacetic acid alkali solution, after the dropwise addition, keep stirring for 8h to obtain reactant A;

[0079] (2) After the heat preservation is over, control the internal temperature not to be higher than 35°C, slowly add concentrated sulfuric acid (300g) dropwise to the reactant A, raise the temperature to about 30°C and stir for half an hour, then stir at 40°C for 4 hours to obtain the reactant B ;

[0080] (3) Cool down to 20-30°C, add toluene (300g) to the reactant B and extract twice, separate the organic phase and the aqueous phase, concentrate the organic ph...

Embodiment 2

[0086] Embodiment 2 A kind of preparation method of gabapentin intermediate

[0087] Specifically include the following steps:

[0088] (1) Cool down to below 10°C, mix 249g of 70% cyanoacetic acid aqueous solution with the lye prepared by adding water (210g) and sodium carbonate (140g), and configure it into cyanoacetic acid alkali solution; control the internal temperature to 30°C, and Cyclohexanone (98g) was slowly added dropwise into the cyanoacetic acid alkali solution, and after the dropwise addition was completed, it was incubated and stirred for 8 hours to obtain reactant A;

[0089] (2) After the heat preservation is over, control the internal temperature not to be higher than 35°C, slowly add 36% concentrated hydrochloric acid (300g) dropwise to the reactant A, heat up to 40°C and stir for half an hour, then stir at 60°C for 4 hours to obtain the reaction Object B;

[0090] (3) cooling to 20-30° C., adding ethyl acetate (300 g) to the reactant B and extracting twic...

Embodiment 3

[0094] Embodiment 3 A kind of preparation method of gabapentin intermediate

[0095] Specifically include the following steps:

[0096] (1) Cool down to below 10°C, mix 249g of 70% cyanoacetic acid aqueous solution with the lye prepared by adding water (210g) and sodium bicarbonate (189g), and configure it into cyanoacetic acid alkaline solution; control the internal temperature to 15°C, Slowly add cyclohexanone (98g) dropwise to the cyanoacetic acid alkali solution, after the dropwise addition, keep stirring for 8h to obtain reactant A;

[0097] (2) After the heat preservation is over, control the internal temperature not higher than 35°C, slowly add 85% concentrated phosphoric acid (346g) dropwise to the reactant A, heat up at 30°C and stir for half an hour, then stir at 40°C for 4 hours to obtain the reaction Object B;

[0098] (3) cooling to 20-30 DEG C, adding xylene (300g) to the reactant B and extracting twice, separating the organic phase and the aqueous phase, conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com