High-temperature-resistant hydrate inhibitor and preparation method thereof

A hydrate inhibitor and high temperature resistant technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of inhibitor degradation failure, poor high temperature resistance effect, inconvenient on-site construction, etc., and achieve the goal of reducing inhibitor Dosage, increase the effect of inhibiting hydration, the effect of convenient injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

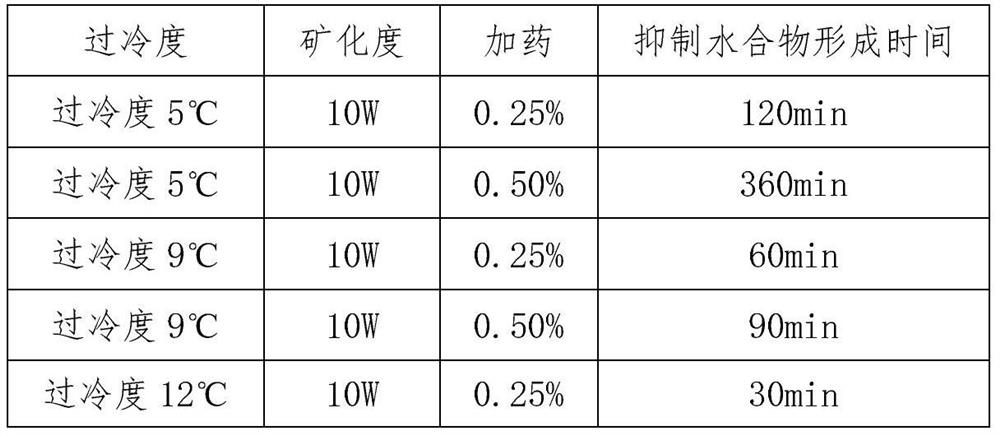

Examples

Embodiment 1

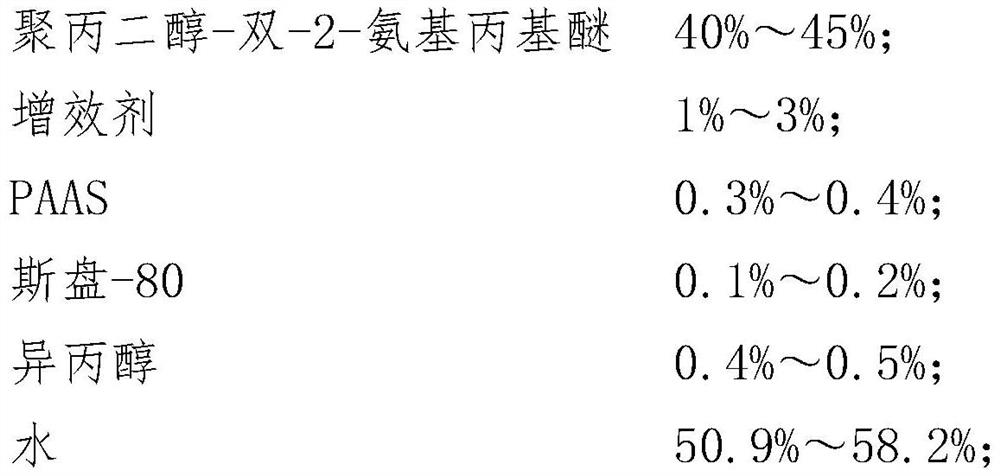

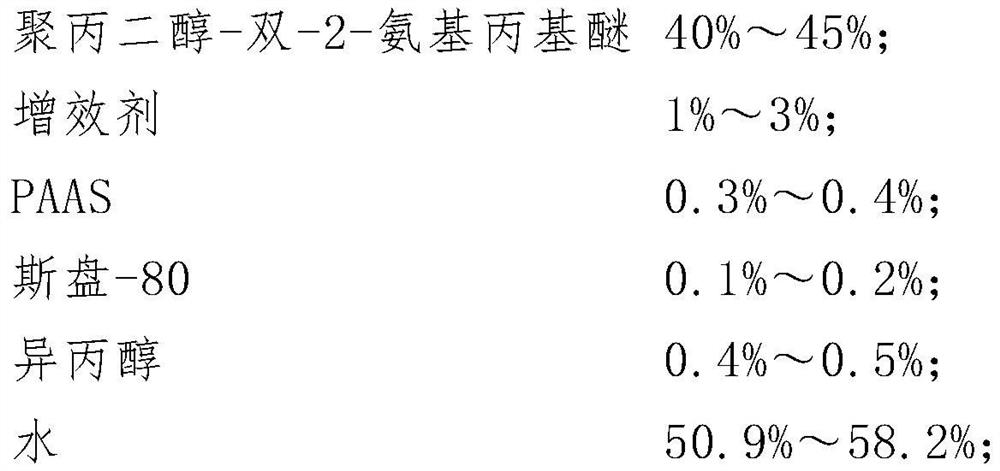

[0029] This embodiment provides a high temperature resistant hydrate inhibitor and its preparation method, the inhibitor includes by mass percentage:

[0030] Polypropylene glycol-bis-2-aminopropyl ether with an average molecular weight of 200-300, 45%;

[0031] Tetraethylenepentamine, 3%;

[0032] PAAS, 0.4%;

[0033] Span-80, 0.2%;

[0034] Isopropanol, 0.5%;

[0035] Water, 50.9%.

[0036] Among the above ratios, the high-temperature-resistant PAAS has better compatibility with high-minerality brine, and it can be combined with polypropylene glycol-bis-2-aminopropyl ether to achieve the inhibition of hydrates at high temperatures.

[0037] The preparation process of above-mentioned inhibitor is as follows:

[0038] First, add 50.9% of water, 0.2% of Span-80, and 0.5% of isopropanol into the reactor, and stir for 30 minutes; then add 0.4% of PAAS into the reactor and stir for 20 minutes; Ethylenepentamine was added into the reactor and stirred for 20 minutes;

[0039]...

Embodiment 2

[0041] This embodiment provides a high temperature resistant hydrate inhibitor and its preparation method, the inhibitor includes by mass percentage:

[0042] Polypropylene glycol-bis-2-aminopropyl ether with an average molecular weight of 200-300, 40%;

[0043] Diethylenetriamine, 1%;

[0044] PAAS, 0.3%;

[0045] Span-80, 0.1%;

[0046] Isopropanol, 0.4%;

[0047] Water, 58.2%.

[0048] The preparation process of above-mentioned inhibitor is as follows:

[0049] First, 58.2% of water, 0.1% of Span-80, and 0.4% of isopropanol were added to the reactor and stirred for 30 minutes; then 0.3% of PAAS was added into the reactor and stirred for 20 minutes; Ethylenetriamine was added to the reactor and stirred for 20 minutes;

[0050] Finally, heat up 40% of the polypropylene glycol-bis-2-aminopropyl ether reactor with an average molecular weight of 200-300 to 140°C, stir and react for 2-3 hours, and cool down to normal temperature to obtain uniform high-temperature-resistant ...

Embodiment 3

[0052] This embodiment provides a high temperature resistant hydrate inhibitor and its preparation method, the inhibitor includes by mass percentage:

[0053] Polypropylene glycol-bis-2-aminopropyl ether with an average molecular weight of 200-300, 42%;

[0054] Diethylenetriamine, 1%, triethylenetetramine 1%, tetraethylenepentamine 1%;

[0055] PAAS, 0.35%;

[0056] Span-80, 0.15%;

[0057] Isopropanol, 0.45%;

[0058] Water, 54.05%.

[0059] The preparation process of above-mentioned inhibitor is as follows:

[0060] First, add 42% of water, 0.15% of Span-80, and 0.45% of isopropanol into the reactor, and stir for 30 minutes; then add 0.35% of PAAS into the reactor and stir for 20 minutes; Ethylenetriamine, triethylenetetramine, and tetraethylenepentamine mixture were added into the reactor and stirred for 20 minutes;

[0061] Finally, heat up 42% of the polypropylene glycol-bis-2-aminopropyl ether reactor with an average molecular weight of 200-300 to 140°C, stir and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com