Batch production method of sulfide solid electrolyte

A solid electrolyte, mass production technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrochemical generators and other directions, can solve the problems of cumbersome, poor batch stability of materials, time-consuming and laborious preparation process, etc. Reduce the preparation cost and meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

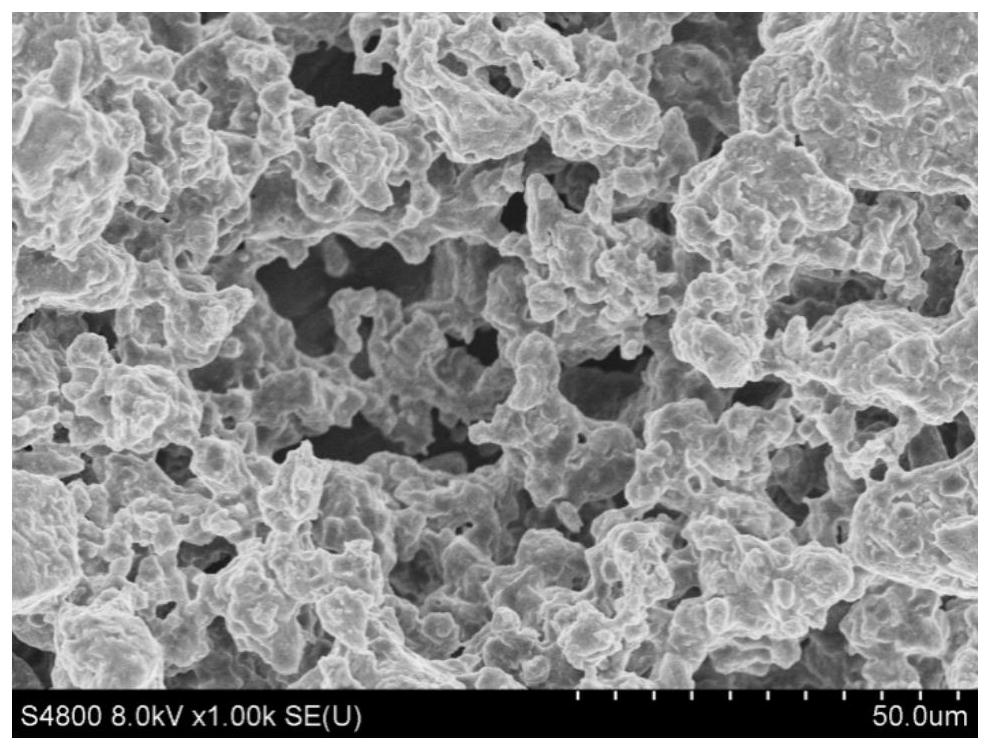

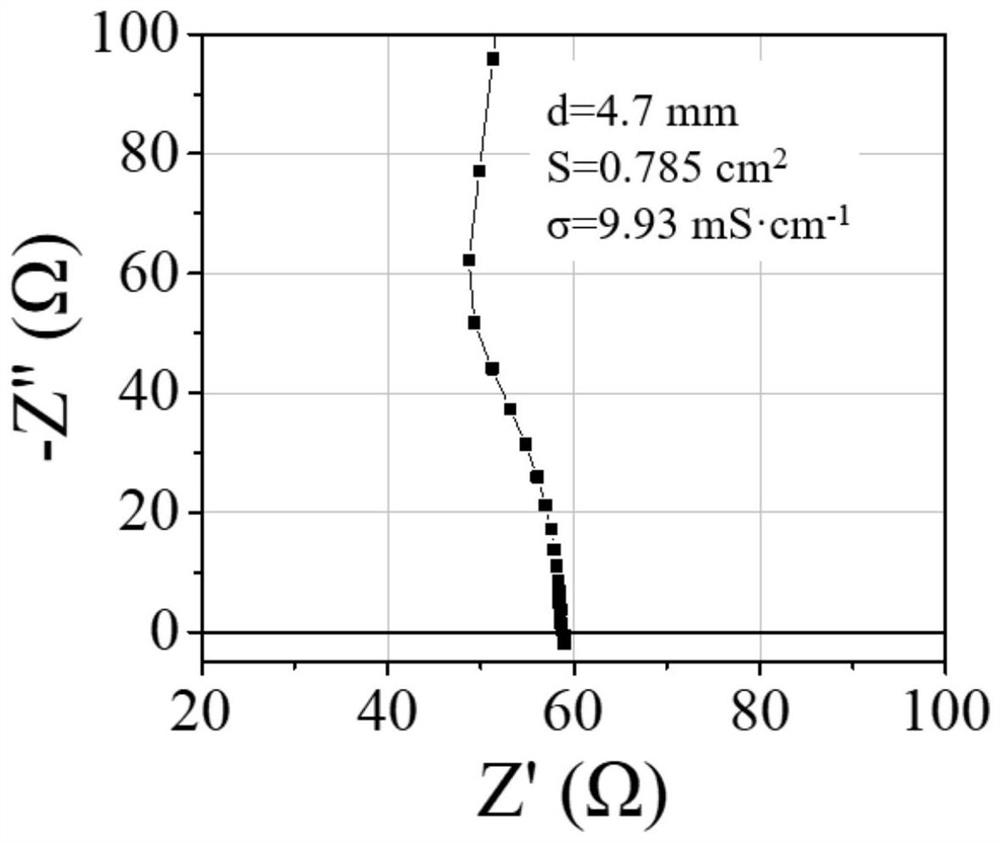

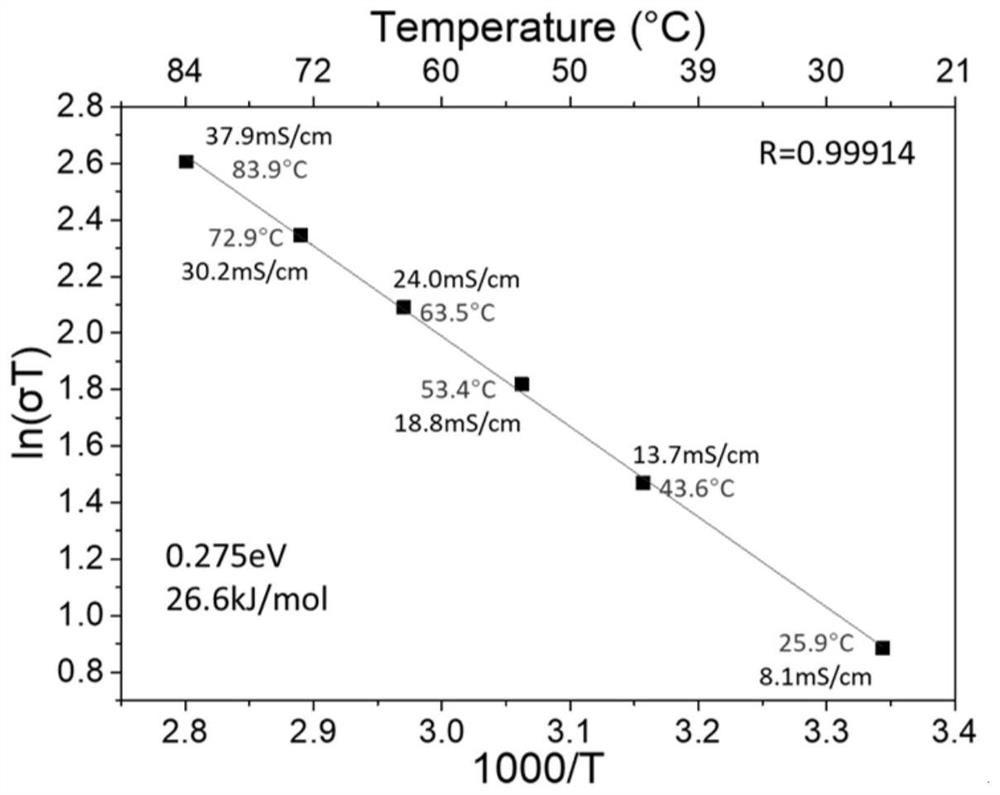

Image

Examples

Embodiment 1

[0060] A batch production method of sulfide solid electrolyte, comprising the following steps:

[0061] 1) Put the raw material Li in the glove box 2 S, P 2 S 5 , LiCl is fed into the mixing device according to the molar ratio of 1.9:0.5:1.6, the water content of the glove box is ≤0.01PPm, the oxygen content is ≤0.01PPm, and the atmosphere of the glove box is nitrogen;

[0062] 2) Seal the mixing device with the raw materials, start mixing, first mix at a low speed, the speed of the mixer is 200rmp / min, forward and reverse each 1min, the mixing time is 30min; then mix at a high speed, the speed is 10000rmp / min, Turn in one direction, each mixing time is 2 minutes, and the total mixing time is 10 minutes; during this process, the inner cavity temperature of the mixing device does not exceed 100°C, and the surface temperature of the mixed powder does not exceed 200°C;

[0063] 3) Demagnetize the mixed powder, the magnetic field strength is 1.5T, and the demagnetization times ...

Embodiment 2-8

[0073] A batch production method of sulfide solid electrolyte, comprising the following steps:

[0074] Compared with Example 1, Example 2-8 has changed the ratio of raw materials, and other operations remain unchanged.

[0075]

Embodiment 9-17

[0077] A batch production method of sulfide solid electrolyte, comprising the following steps:

[0078] Compared with Example 1, Examples 9-17 changed the mixing conditions and sintering conditions, and other conditions remained unchanged.

[0079]

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com