Chocolate-flavored coated cake with biscuit crumbles scattered on surface and making method of chocolate-flavored coated cake

A chocolate and cake technology, applied in coating preservation, baking, baked goods, etc., can solve the problems of aging taste of fillings, sticky cake body, and dryness, etc., to extend shelf life, prevent migration, and prevent moisture The effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

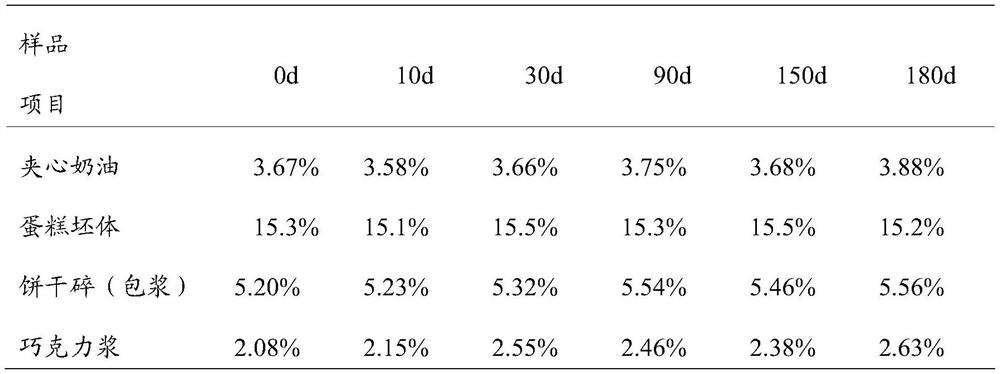

Examples

Embodiment 1

[0049] A chocolate-flavored coated cake sprinkled with biscuit crumbs on the surface, comprising a cake body and a chocolate coating layer wrapped on the outer surface of the cake body, the cake body is provided with a sandwich cream layer, and the chocolate coating layer Decorated with biscuit crumbs.

[0050] The cake body includes the following components: by weight, 95 parts of low-gluten flour, 85 parts of white sugar powder, 190 parts of whole egg liquid, 65 parts of salad oil, 2 parts of milk powder, 2 parts of condensed milk, 2 parts of baking powder, salt 2 parts, 2 parts of sodium alginate, 14 parts of emulsifier, 0.3 parts of vanilla powder, 0.3 parts of sodium dehydroacetate, 48 parts of water and 1 part of edible alcohol.

[0051] The sandwich cream includes the following components: by weight, 100 parts of anhydrous butter, 30 parts of white sugar powder, 30 parts of glucose powder, 1 part of salt powder, 10 parts of fructose syrup, 5 parts of dietary fiber powde...

Embodiment 2

[0094] A chocolate-flavored coated cake sprinkled with biscuit crumbs on the surface, comprising a cake body and a chocolate coating layer wrapped on the outer surface of the cake body, the cake body is provided with a sandwich cream layer, and the chocolate coating layer Decorated with biscuit crumbs.

[0095] The cake body includes the following components: by weight, 105 parts of low-gluten flour, 95 parts of white sugar powder, 210 parts of whole egg liquid, 75 parts of salad oil, 3 parts of milk powder, 3 parts of condensed milk, 2.5 parts of baking powder, 2 parts of table salt, 2 parts of sodium alginate, 16 parts of emulsifier, 0.3 parts of vanilla powder, 0.3 parts of sodium dehydroacetate, 52 parts of water, 1 part of edible alcohol;

[0096] Its sandwich cream includes the following components: by weight, 100 parts of anhydrous butter, 30 parts of white sugar powder, 30 parts of glucose powder, 1 part of salt powder, 10 parts of fructose syrup, 5 parts of dietary fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com