Preparation method and application of nitrogen-containing super-crosslinked polymer derived Co@CN catalyst

A polymer and hypercrosslinking technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve unfavorable industrial applications, high cost of catalyst preparation and use, and weak electron transfer promotion effect. and other problems, to achieve the effect of facilitating large-scale production and application, improving electron transfer performance, and reducing preparation and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

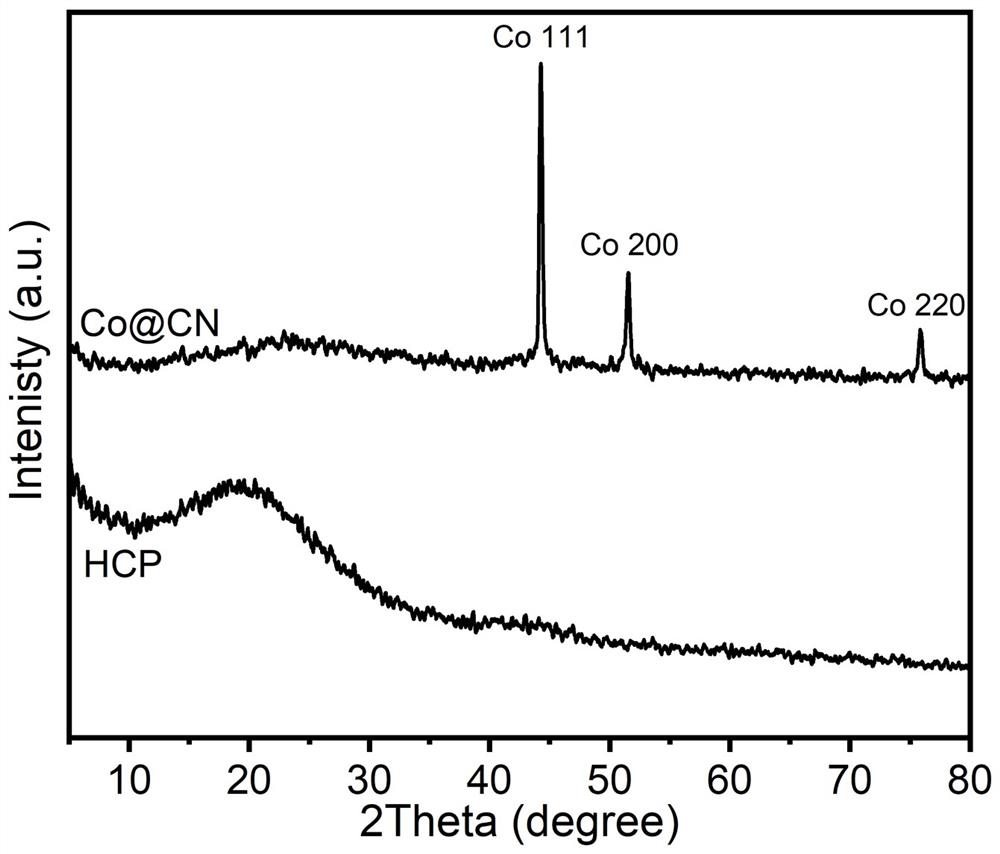

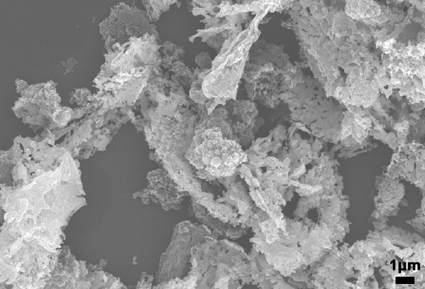

[0026] A method for preparing a Co@CN catalyst derived from a nitrogen-containing hypercrosslinked polymer, comprising the steps of:

[0027] S1. Dissolve 10 mmol benzotriazole, 30 mmol benzene, 6.5 g dimethoxymethane, and 9.5 g anhydrous ferric chloride in 100 mL 1,2-dichloroethane, heat to 80 °C, and It fully reacted for 24 h. The product was Soxhlet-extracted with methanol for 24 hours to remove impurities, and then spin-dried with a rotary evaporator to obtain a nitrogen-containing hypercrosslinked polymer.

[0028] S2. Disperse 1 g of the above polymer and 1.48 g of cobalt nitrate hexahydrate into 50 mL of deionized water, add 0.5 g of urea and transfer to a polytetrafluoroethylene-lined stainless steel reactor, and fix the sealed autoclave in a uniform The rotating shaft of the phase reactor was turned over at a speed of 60 rpm, the temperature was set at 170 °C, and the treatment time was 9 h. After cooling, the solid was collected by filtration, washed with deionized...

Embodiment 2

[0035] S1. Dissolve 10 mmol benzotriazole, 30 mmol benzene, 6.5 g dimethoxymethane, and 9.5 g anhydrous ferric chloride in 100 mL 1,2-dichloroethane, heat to 80 °C, and It fully reacted for 24 h. The product was Soxhlet-extracted with methanol for 24 hours to remove impurities, and then spin-dried with a rotary evaporator to obtain a nitrogen-containing hypercrosslinked polymer.

[0036] S2. Disperse 1 g of the above polymer and 0.80 g of cobalt acetate into 50 mL of deionized water, add 0.5 g of urea and transfer to a polytetrafluoroethylene-lined stainless steel reactor, and fix the sealed autoclave in a homogeneous reaction Turn over at a speed of 60 rpm on the rotating shaft of the machine, set the temperature at 170 °C, and process for 9 h. After cooling, the solid was collected by filtration, washed with deionized water until neutral, and dried overnight at 80 °C to obtain the precursor for purification.

[0037] S3. Spread 500 mg of the precursor on the bottom of the ...

Embodiment 3

[0040] A method for preparing a Co@CN catalyst derived from a nitrogen-containing hypercrosslinked polymer, comprising the steps of:

[0041] S1. Dissolve 10 mmol of benzimidazole, 30 mmol of benzene, 6.5 g of dimethoxymethane, and 9.5 g of anhydrous ferric chloride in 100 mL of 1,2-dichloroethane, and heat to 80 °C to fully React for 24 h. The product was Soxhlet-extracted with methanol for 24 h to remove impurities, and then spin-dried with a rotary evaporator to obtain a nitrogen-containing hypercrosslinked polymer.

[0042] S2. Disperse 1 g of the above polymer and 1.35 g of cobalt nitrate hexahydrate into 50 mL of deionized water, add 0.5 g of urea and transfer to a polytetrafluoroethylene-lined stainless steel reactor, and fix the sealed autoclave in a uniform The rotating shaft of the phase reactor was turned over at a speed of 60 rpm, the temperature was set at 170 °C, and the treatment time was 9 h. After cooling, the solid was collected by filtration, washed with d...

PUM

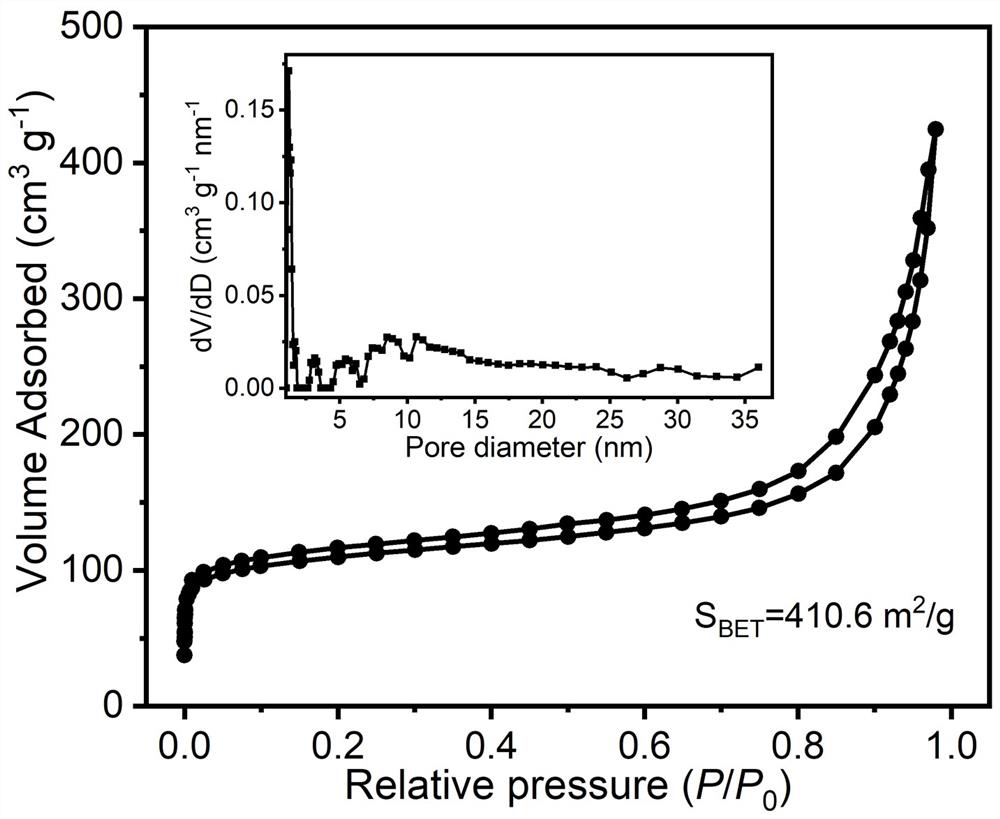

| Property | Measurement | Unit |

|---|---|---|

| Bet surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com