Formaldehyde adsorbent

A formaldehyde adsorption and formaldehyde remover technology, applied in the fields of alkali metal oxides/hydroxides, inorganic chemistry, gas treatment, etc., can solve the problems of replacement, secondary pollution, limited adsorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

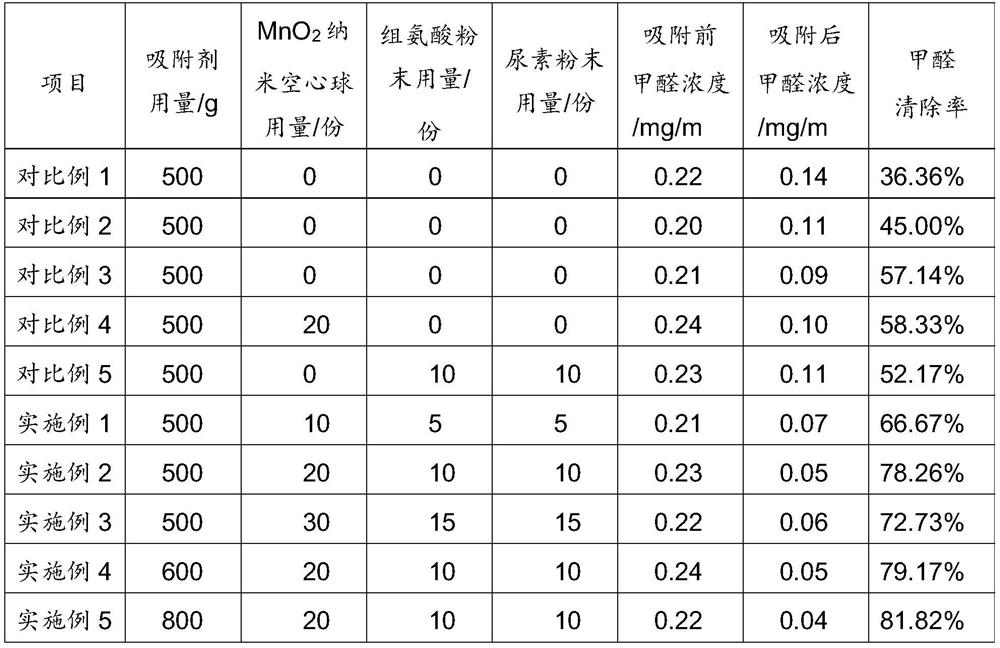

Embodiment 1

[0053] Embodiment 1: In parts by weight, 100 parts of manganese dioxide-loaded and modified sargassum-based activated carbon, MnO 2 10 parts of hollow nanospheres, 5 parts of histidine powder, and 5 parts of urea powder are prepared according to the aforementioned method to obtain the formaldehyde adsorbent, packed in 500 g.

Embodiment 2

[0054] Embodiment 2: In parts by weight, 100 parts of manganese dioxide-loaded and modified sargassum-based activated carbon, MnO 2 20 parts of hollow nanospheres, 10 parts of histidine powder, and 10 parts of urea powder are prepared according to the aforementioned method to obtain the formaldehyde adsorbent, packed in 500 g.

Embodiment 3

[0055] Embodiment 3: In parts by weight, 100 parts of manganese dioxide-loaded and modified sargassum-based activated carbon, MnO 2 30 parts of hollow nanospheres, 15 parts of histidine powder, and 15 parts of urea powder are prepared according to the aforementioned method to obtain the formaldehyde adsorbent, packed in 500 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com