Triazinyl covalent network loaded metal single atom composite material, preparation method and application thereof

A composite material, network loading technology, applied in the field of electrocatalysis, can solve problems such as easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

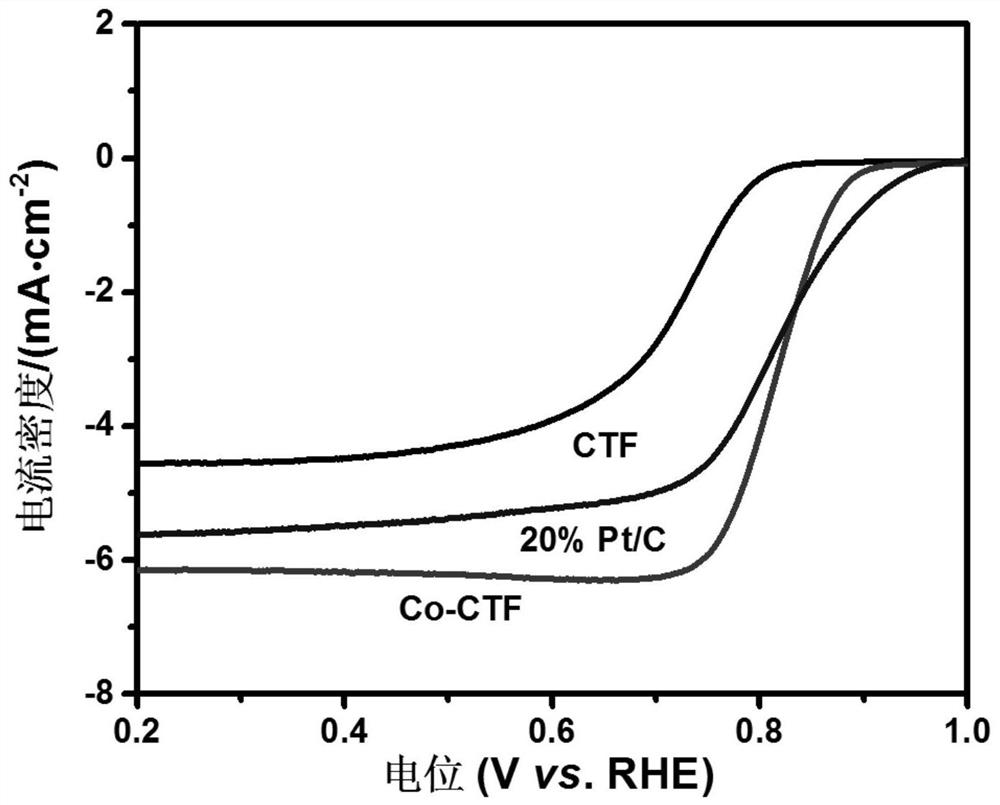

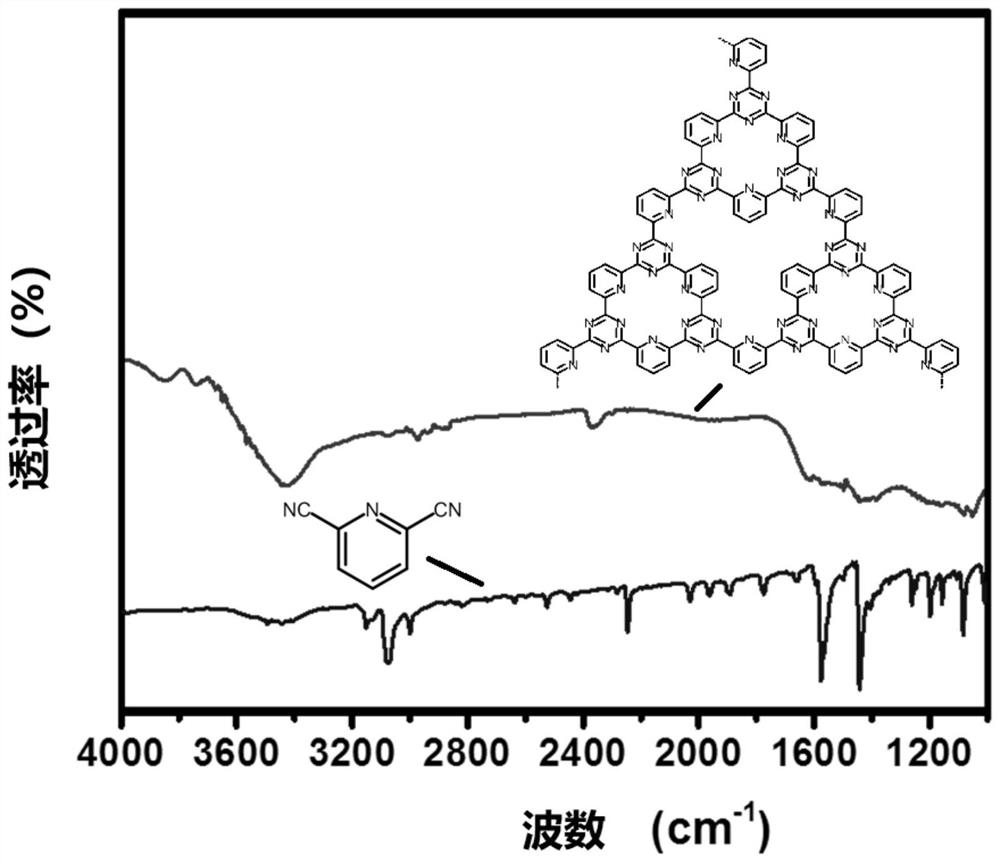

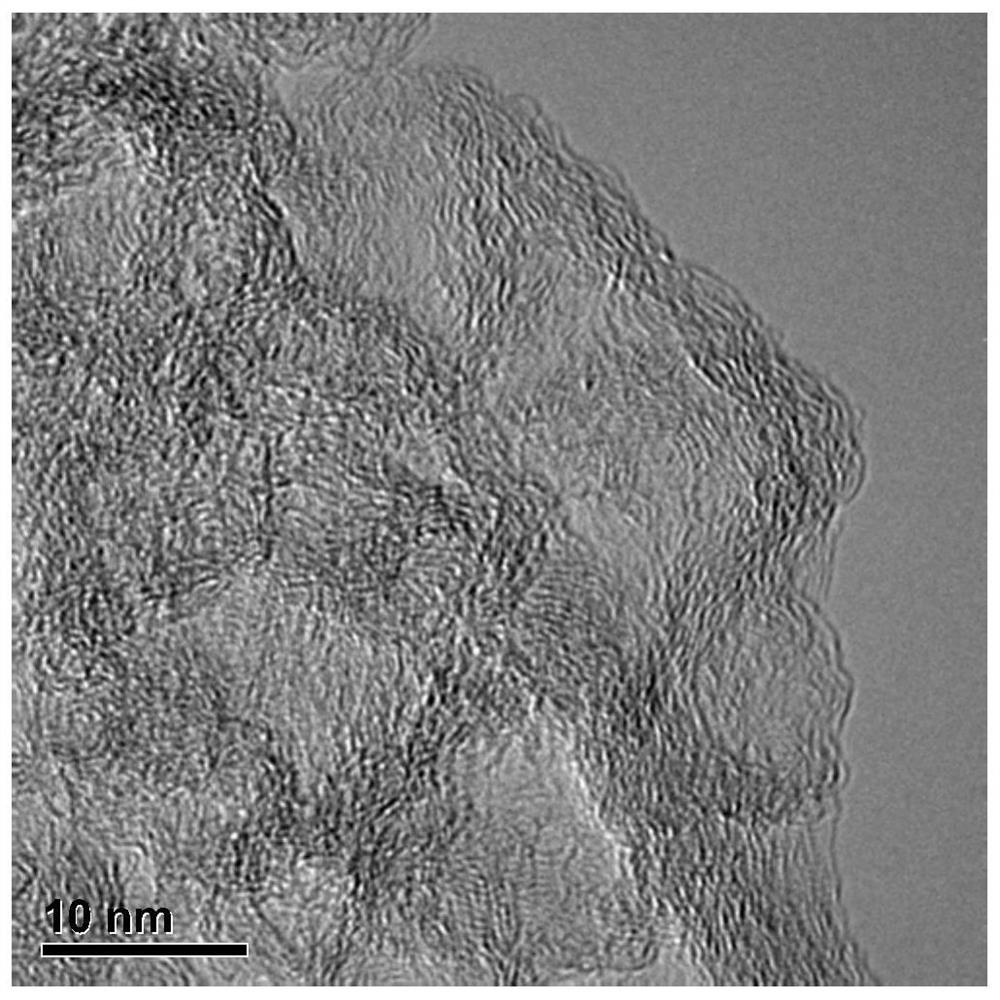

[0059] The invention provides a composite material with a triazine-based covalent network supporting metal single atoms. The composite material comprises a triazine-based covalent network and transition metal single-atom cobalt supported on the triazine-based covalent network. Its preparation method comprises the following steps:

[0060] (1) Mix 2,6-pyridinedicarbonitrile, Ketjen Black EC600JD and zinc chloride, grind and mix them evenly in a glove box, then put them into sealed tubes, and use double-row tubes for argon gas exchange during the tube sealing process After three times, the sealed tube was vacuumed, sintered and sealed, and the sealed tube was placed in a muffle furnace, and the temperature was raised to 400 °C at a rate of 5 °C / min for cyanotrimerization reaction for 21 h; wherein 2,6-pyridinedicarbonitrile and The molar ratio of zinc chloride is 1:5, and the mass ratio of 2,6-pyridinedicarbonitrile to Ketjen Black EC600JD is 1:1;

[0061] (2) The product obtai...

Embodiment 2

[0072] The invention provides a composite material with a triazine-based covalent network supporting metal single atoms. The composite material comprises a triazine-based covalent network and transition metal single-atom cobalt supported on the triazine-based covalent network. Its preparation method comprises the following steps:

[0073] (1) Mix 2,6-pyridinedicarbonitrile, Ketjen Black EC600JD and zinc chloride, grind and mix them evenly in a glove box, then put them into sealed tubes, and use double-row tubes for argon gas exchange during the tube sealing process After three times, the sealed tube was vacuumed, sintered and sealed, and the sealed tube was placed in a muffle furnace, and the temperature was raised to 600 °C at a rate of 10 °C / min for cyanotrimerization reaction for 30 h; wherein 2,6-pyridinedicarbonitrile and The molar ratio of zinc chloride is 1:10, and the mass ratio of 2,6-pyridinedicarbonitrile to Ketjen Black EC600JD is 1:5;

[0074] (2) The product obt...

Embodiment 3

[0079] The invention provides a composite material with a triazine-based covalent network supporting metal single atoms. The composite material comprises a triazine-based covalent network and transition metal single-atom cobalt supported on the triazine-based covalent network. Its preparation method comprises the following steps:

[0080] (1) Mix 2,6-pyridinedicarbonitrile, Ketjen Black EC600JD and zinc chloride, grind and mix them evenly in a glove box, then put them into sealed tubes, and use double-row tubes for argon gas exchange during the tube sealing process After three times, the sealed tube was vacuumed, sintered and sealed, and the sealed tube was placed in a muffle furnace, and the temperature was raised to 700 °C at a rate of 2 °C / min for cyanotrimerization reaction for 20 h; in which 2,6-pyridinedicarbonitrile and The molar ratio of zinc chloride is 1:20, and the mass ratio of 2,6-pyridinedicarbonitrile to Ketjen Black EC600JD is 1:2;

[0081] (2) The product obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com