Device and method for preparing directionally-distributed chopped carbon fiber reinforced composite material

A technology of reinforced composite materials and chopped carbon fibers, which is applied in the direction of clay preparation equipment, clay mixing equipment, chemical instruments and methods, etc., can solve the problems such as the inability of fibers to be oriented, and achieve the effect of improving the degree of automation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

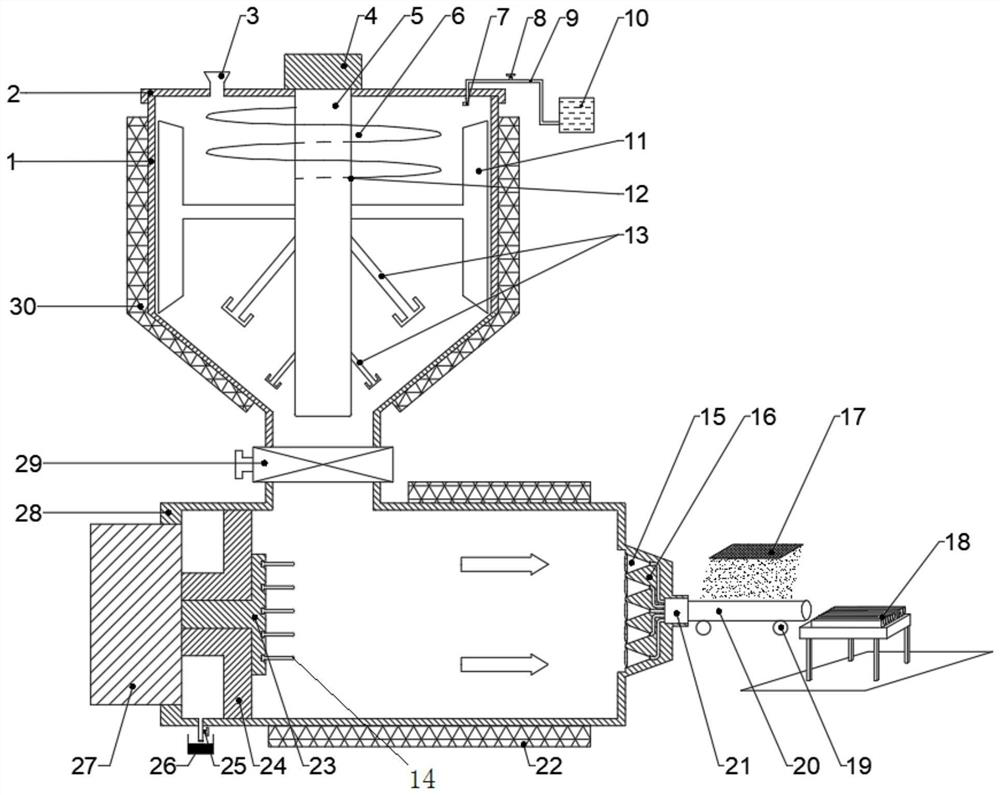

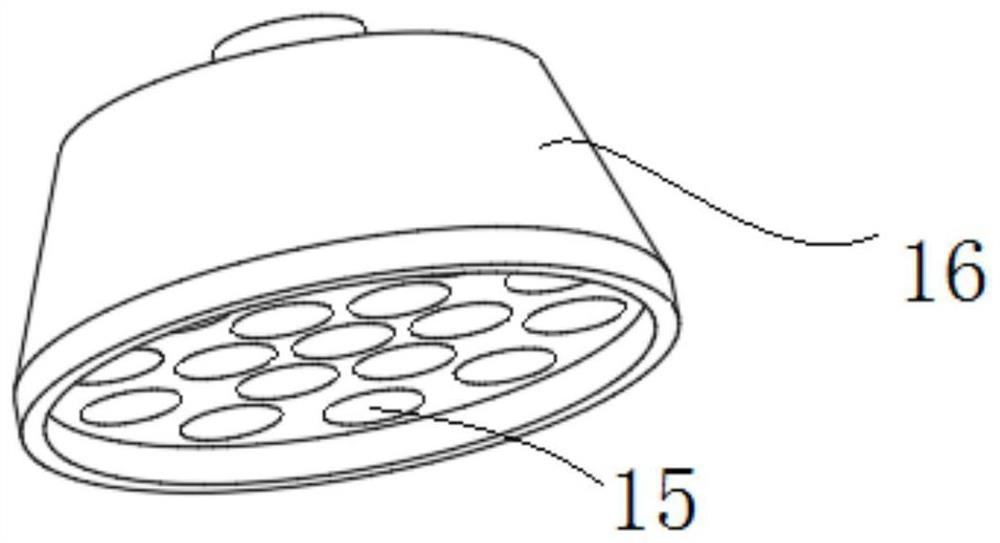

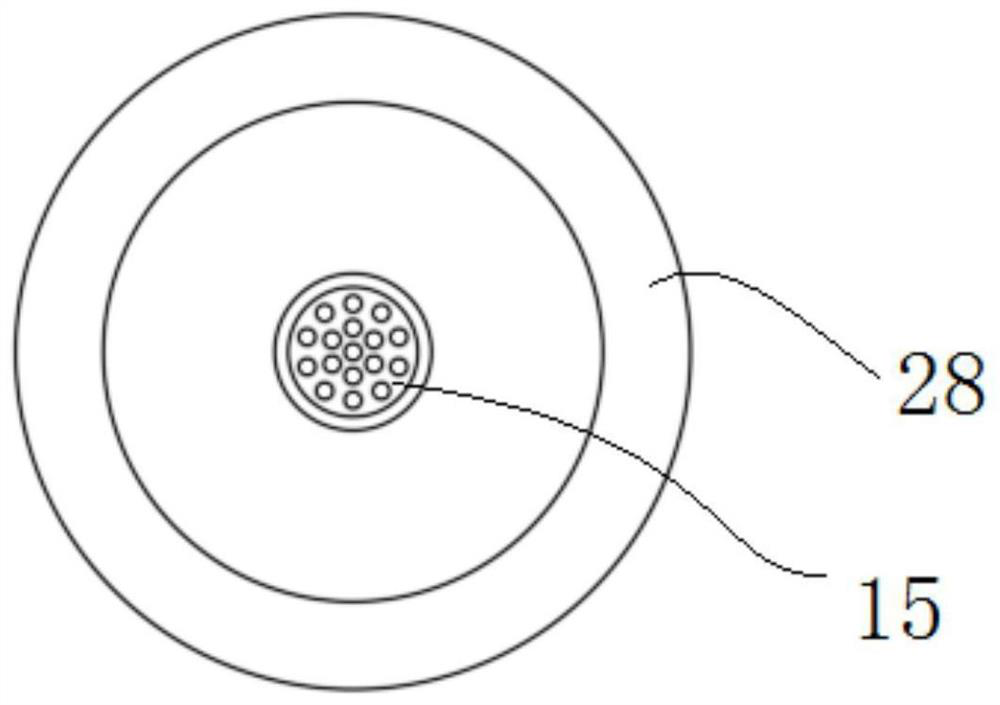

[0045] see figure 1 and Figure 6 Shown:

[0046] In this embodiment, a directional distributed chopped carbon fiber reinforced hydroxyapatite-based composite material is prepared, including the following steps:

[0047] Step 1: Select the composition and mass percentage of raw materials

[0048] Chopped carbon fiber 0.5%: chopped carbon fiber average diameter 7μm, length 2-3mm;

[0049] Dispersant system 2%: the amount of surfactant 1%; the amount of dispersant 1%, the dispersant is composed of polyethylene oxide (PEO) and polyacrylamide (PAM) with a mass ratio of 3:1;

[0050] Matrix material 97.5%: hydroxyapatite powder;

[0051] Step 2: Pre-dispersion of Chopped Carbon Fiber

[0052] Take a beaker, pour the weighed chopped carbon fiber, surfactant, and dispersant into the beaker, then add a certain amount of deionized water, and stir with a glass rod to disperse the chopped carbon fiber evenly; then extend the ultrasonic probe into In the liquid, with a power of 800W...

Embodiment 2

[0061] The steps of this embodiment and embodiment 1 are the same, and the difference is that the components of the raw materials in step 1 are different. In the present embodiment, the mass percentages of the raw materials are as follows:

[0062] Chopped carbon fiber 0.3%: chopped carbon fiber average diameter 7μm, length 2-3mm;

[0063] Dispersant system 2%: the amount of surfactant is 0.4%; the amount of dispersant is 1.6%, and the dispersant is composed of polyethylene oxide (PEO) and polyacrylamide (PAM) with a mass ratio of 3:1;

[0064] The balance is matrix material.

Embodiment 3

[0066] The steps of this embodiment and embodiment 1 are the same, and the difference is that the components of the raw materials in step 1 are different. In the present embodiment, the mass percentages of the raw materials are as follows:

[0067] Chopped carbon fiber 0.8%: chopped carbon fiber average diameter 7μm, length 2-3mm;

[0068] Dispersant system 1%: the amount of surfactant is 0.2%; the amount of dispersant is 0.8%, and the dispersant is composed of polyethylene oxide (PEO) and polyacrylamide (PAM) with a mass ratio of 3:1;

[0069] The balance is matrix material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com