Method for catalyzing alkylation reaction by using phase transfer

An alkylation reaction and phase transfer catalyst technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of increased separation difficulty, long reaction time and high temperature, and achieve simplified post-treatment process, The effect of lowering the reaction temperature and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

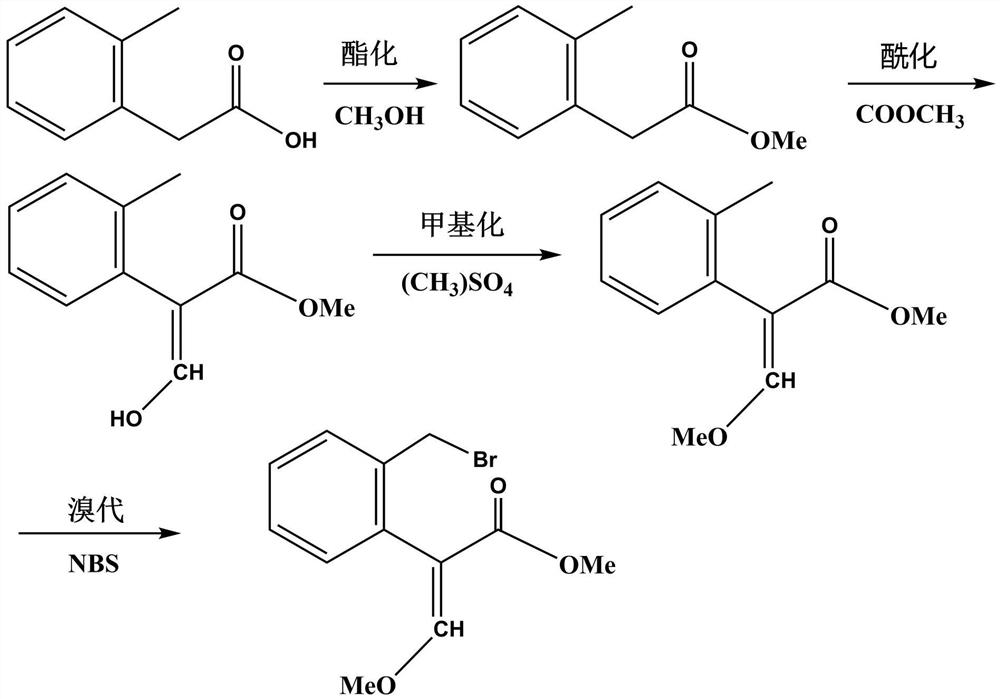

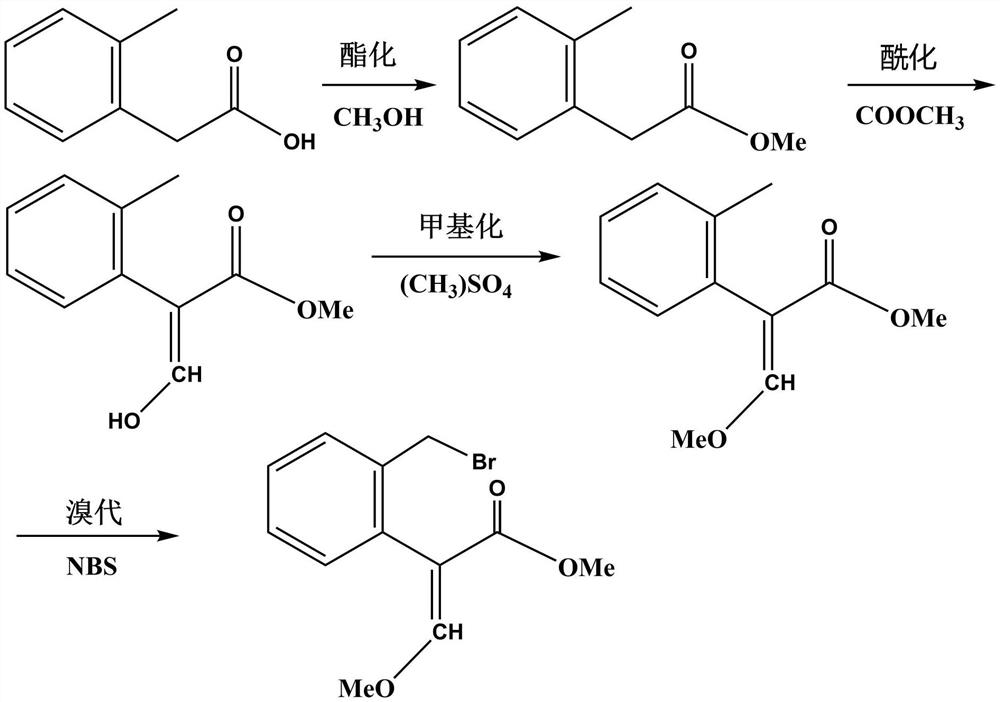

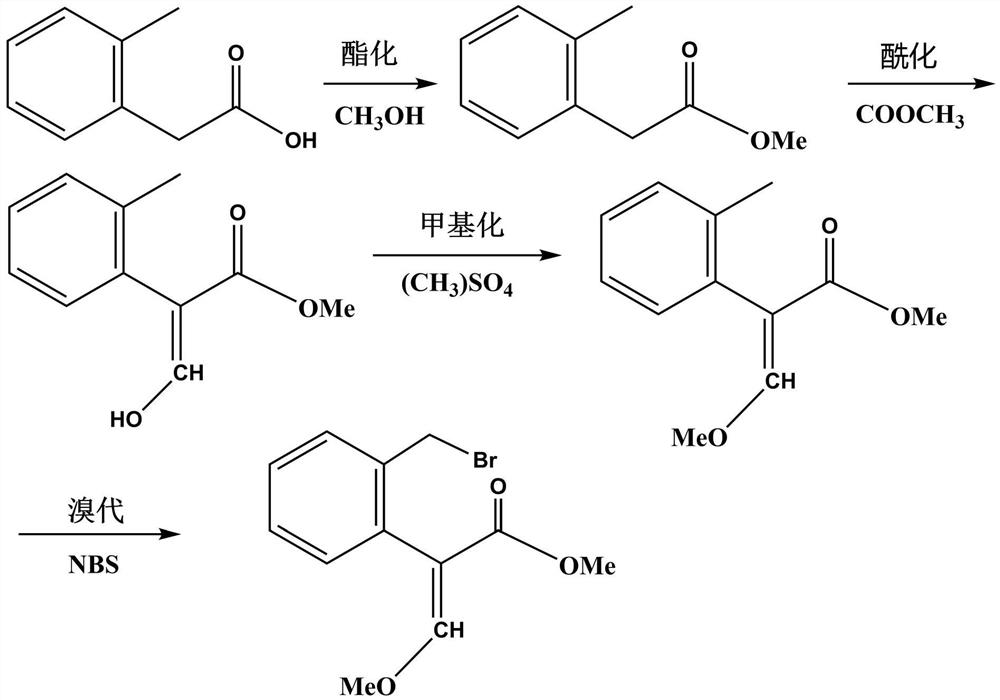

[0020] The chemical reaction equation that o-methylphenylacetic acid prepares methyl bromophenylacrylate is as follows,

[0021]

[0022] The one-step original process of methylation reaction is as follows:

[0023] Dissolve the acylate in acetone, add metered dimethyl sulfate, potassium carbonate (or KOH), stir, heat and reflux for 3 hours, cool and filter, precipitate, extract with dichloromethane, wash the organic phase, dry, filter, and remove dichloromethane to obtain a yellow liquid , The yield is about 85%.

[0024] In the technology provided by the invention as follows:

[0025] In the acylate dichloromethane solution after the above reaction, directly add a phase transfer catalyst with a mass ratio between 1% and 2%, and then add 40-50% KOH aqueous solution dropwise. Add dimethyl sulfate, then raise the temperature to room temperature, trace the reactants drop by drop within 0.5-1h until the reaction is complete, add a certain amount of water and let stand to sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com