PTFE coated particle with core-shell structure and preparation method thereof

A technology of PTFE and core-shell structure, which is applied in the field of preparation of PTFE-coated particles, and can solve the problem of PTFE resin reducing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention relates to a preparation method of a PTFE resin with a core-shell structure. The PTFE resin with a core-shell structure prepared by the method has an improved covering degree.

[0025] In the present invention, the term "coating degree" refers to the covered area of the acrylonitrile shell polymer on the surface of the PTFE resin core, which can be obtained qualitatively from the STEM picture of the coated product, and is reflected in the element quantitative analysis calculation based on the STEM picture The elemental molar ratio of N and F, that is, N / F (mol), and according to the elemental ratio of N / F, calculate the amount of wrapped shell polymer in the total polymer (wt%). .

[0026] 1. The preparation method of the PTFE resin of core-shell structure of the present invention comprises the step of providing the acrylonitrile polymer monomer emulsion that acrylonitrile polymer monomer and emulsifier form.

[0027] The emulsifier suitable for the met...

Embodiment

[0070] testing method

[0071] (i) Determination of solid content of PTFE-coated resin emulsion

[0072] Weigh about 5g of polymerized PTFE-coated resin emulsion, heat at 140°C for 2h, weigh to calculate the solid content, and take the average of three experiments.

[0073] (ii) Determination of coagulation rate of PTFE seed emulsion polymerization

[0074] After the polymerization finishes, filter the PTFE, collect the coagulation rate formed by demulsification in the polymerization process, dry, weigh, and calculate the coagulation rate:

[0075] Agglomeration rate (wt%) = aggregate mass / (aggregate mass + filtered emulsion weight * solid content) * 100%

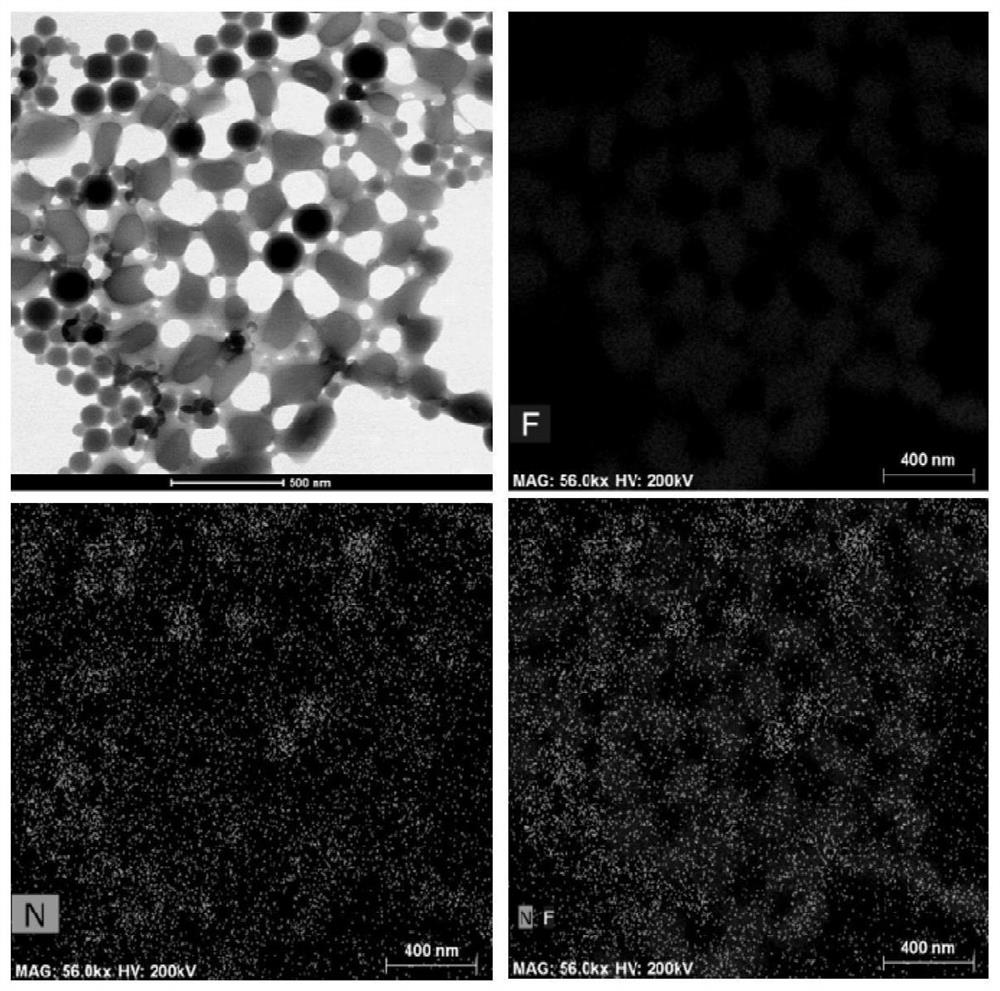

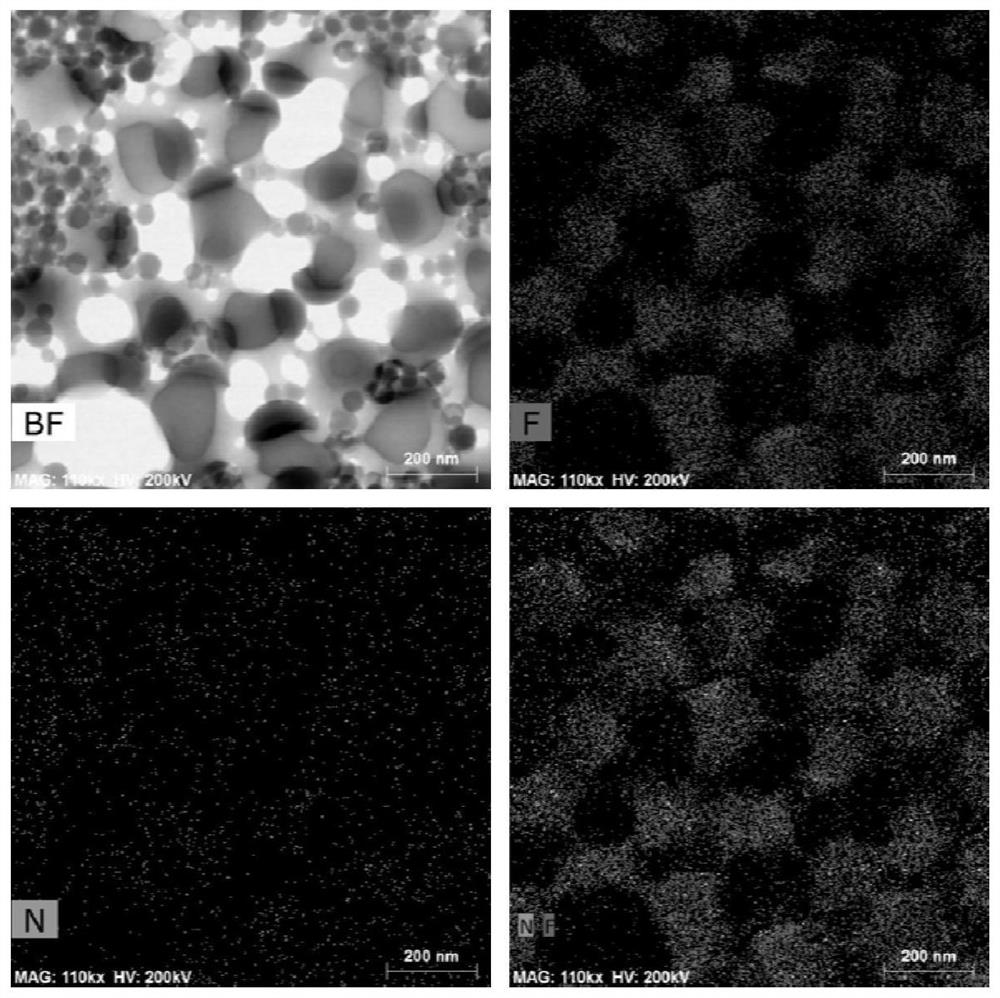

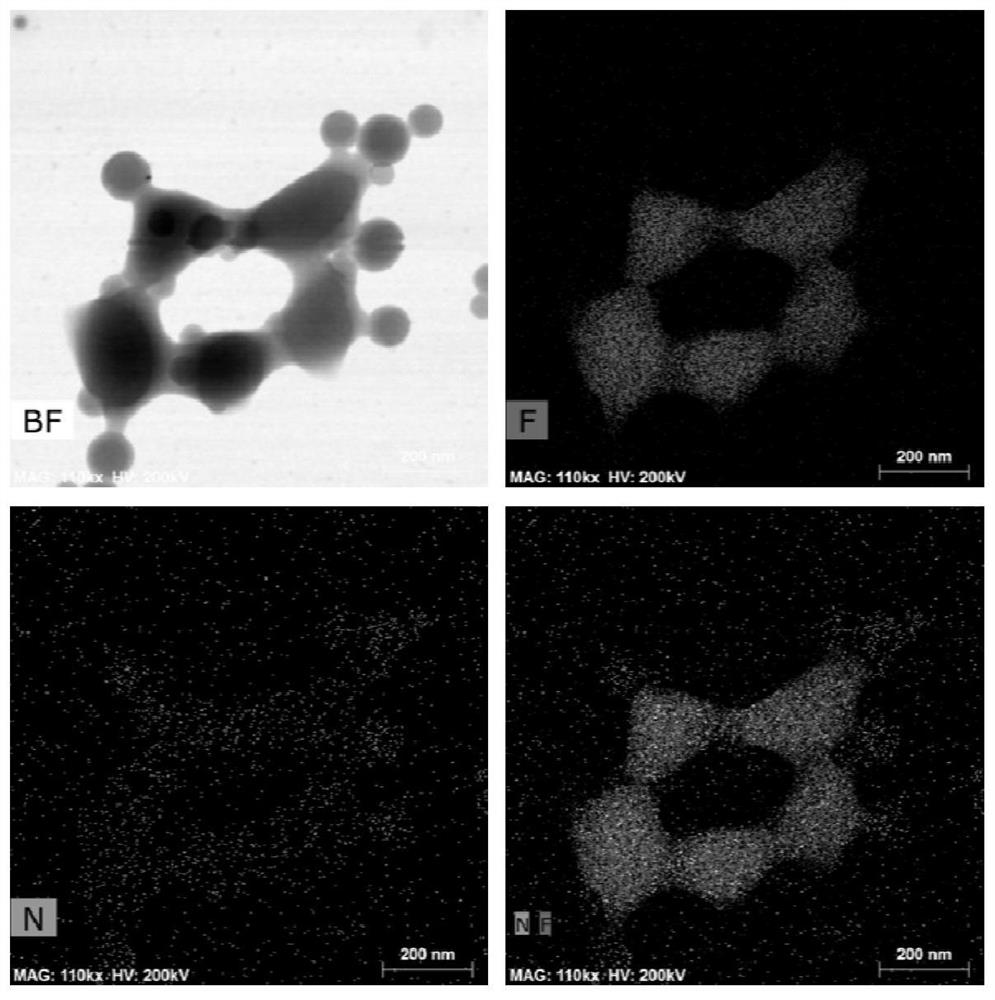

[0076] (iii) Determination of PTFE-coated resin core-shell structure

[0077] Field emission transmission electron microscopy (STEM) was used to observe the wrapping of the shell polymer on the surface of PTFE particles, and the mapping imaging of N (or polymer monomer-specific elements) and F elements was performed. Th...

Embodiment 1

[0106] Weigh 3g of sodium lauryl sulfate, 3g of tridecyl polyoxyethylene ether, add 75g of deionized water to dissolve; add 24g of styrene and 6g of acrylonitrile to the aqueous solution of the above compounded surfactant for pre-emulsification , to obtain a pre-emulsion. Weigh 50g of PTFE emulsion, dilute the 60wt% PTFE concentrated solution to 20wt%, add 3g sodium lauryl sulfate, 3g tridecyl polyoxyethylene ether and 3g dodecyl mercaptan (NDDM), fully stir , dissolved evenly.

[0107] Weigh 2 g of ammonium persulfate, add deionized water to dissolve completely, and obtain an initiator solution. Take 1 / 5 of the above-mentioned pre-emulsion and add it to the mixture of the above-mentioned PTFE emulsion, stir evenly and then raise the temperature to 85°C. Add the initiator solution. Then add the remaining 4 / 5 pre-emulsion dropwise to the above-mentioned PTFE mixed solution to carry out polymerization reaction, control the drop rate, and finish adding the remaining monomers w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com