Sucralose compound, preparation method thereof and atomized essence

A technology of sucralose and compound, applied in the direction of essential oil/spice, fat production, etc., can solve the problems of no substitute, ignoring danger, problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

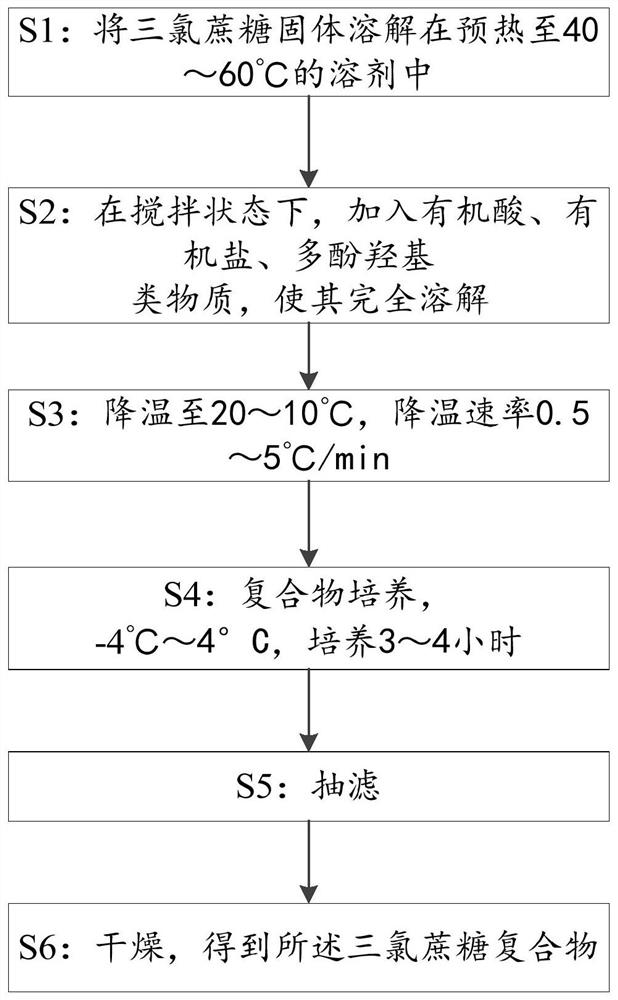

[0046] The second aspect of the present invention proposes a preparation method of sucralose complex, please refer to figure 1 ,include:

[0047] S1: Dissolving sucralose solid in a solvent preheated to 40-60°C.

[0048] S2: While stirring, add organic acid, organic salt, and polyphenolic hydroxyl substances to completely dissolve them.

[0049] S3: Cool down to 20-10°C at a cooling rate of 0.5-5°C / min.

[0050] S4: Composite cultivation, at -4°C to 4°C, for 3 to 4 hours. By culturing the complex, crystals of the sucralose complex were precipitated.

[0051] S5: suction filtration.

[0052] S6: drying to obtain the sucralose complex.

[0053] Optionally, the solvent includes one or more of deionized water, ethanol, acetone, propylene glycol, triethyl citrate, and triacetic anhydride oil ester.

[0054] Preferably, the solvent includes deionized water and ethanol, and the mass ratio of the deionized water to the ethanol is not less than 2. Among them, ethanol helps to di...

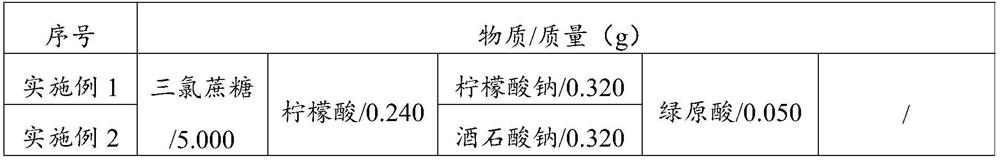

Embodiment 1

[0061] S1: Dissolve 5.0 g of sucralose solid in 25.0 g of deionized water preheated to 45°C.

[0062] S2: Add 0.240 g of citric acid, 0.320 g of sodium citrate, and 0.050 g of chlorogenic acid under stirring at 350 rpm to dissolve them completely.

[0063] S3: Cool down to 18°C with a cooling rate of 1.5°C / min.

[0064] S4: The complex was cultured at 4° C. for 3 hours, and the crystals of the sucralose complex were precipitated.

[0065] S5: suction filtration.

[0066] S6: Drying. The sucralose complex crystals on the filter paper after suction filtration were taken, placed in an oven at 30° C., and vacuum-dried for 3 hours to obtain the sucralose complex of Example 1.

Embodiment 2

[0068] S1: Dissolve 5.0 g of sucralose solid in 25.0 g of deionized water preheated to 45°C.

[0069] S2: Add 0.240 g of citric acid, 0.320 g of sodium tartrate, and 0.050 g of chlorogenic acid under stirring at 350 rpm to dissolve them completely.

[0070] S3: Cool down to 18°C with a cooling rate of 1.5°C / min.

[0071] S4: The complex was cultured at 4° C. for 3 hours, and the crystals of the sucralose complex were precipitated.

[0072] S5: suction filtration.

[0073] S6: drying, taking the sucralose complex crystals on the filter paper after suction filtration, placing them in an oven at 30° C., and drying in vacuum for 3 hours to obtain the sucralose complex of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com