Soap composition containing microcapsule essence and production method thereof

A technology of microcapsule essence and composition, which is applied in the direction of fragrance-containing washing composition, synthetic soap composition, soap detergent composition, etc., and can solve the problem of limited application, difficulty in the stable existence of microcapsule essence, and destruction of microcapsule by production process Capsule and other problems, to achieve the effect of pleasant mood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

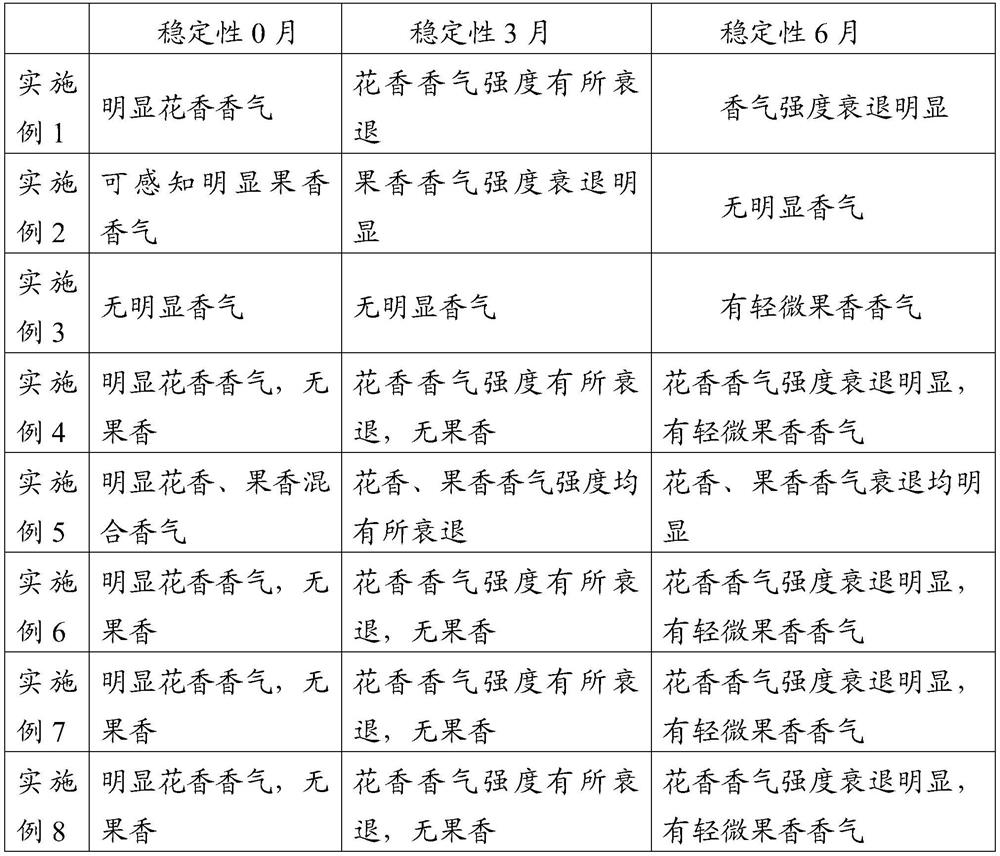

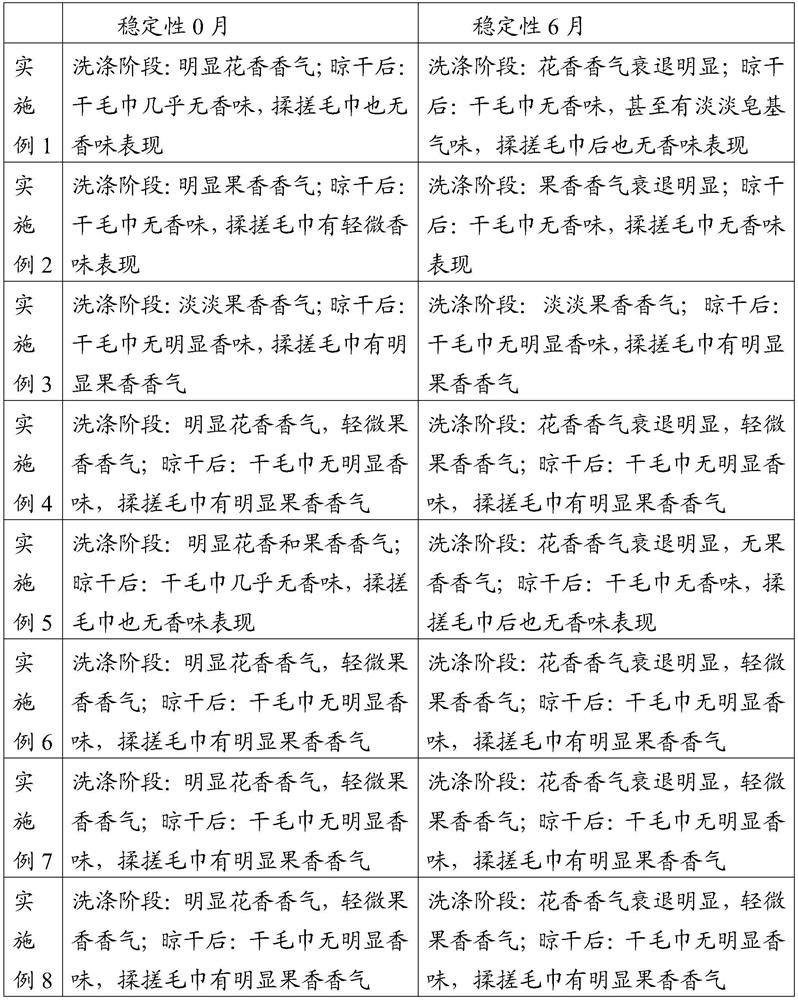

Examples

Embodiment 1

[0037] A microcapsule essence soap composition, which is made of the following substances in weight percent: 75.0 parts of sodium fatty acid, 0.5 part of tetrasodium edetate, 0.4 part of floral liquid essence, 0.01 part of acidic golden yellow G Pigment, the balance of water mixed.

[0038] Fatty acid sodium is selected from mixed oil fatty acid salt, which is obtained by mixing tallow and coconut oil in a certain proportion, and then undergoing saponification reaction or hydrolysis and neutralization. Sodium fatty acid and water are prepared according to a certain ratio to obtain soap particles. The ratio of fatty acid sodium salt and water can be controlled synergistically by the soap particles and the preparation process of the composition.

[0039] The production method and the processing conditions thereof of the essence soap composition containing capsules are as follows:

[0040] 1) Add the weighed soap particles into the mixing pot, stir for 2 minutes and pulverize eve...

Embodiment 2

[0046] A soap composition containing microcapsule essence, which is made of the following substances in weight percent: 75.0 parts of sodium fatty acid, 0.5 part of tetrasodium edetate, 0.4 part of fruity microcapsule essence, 0.01 part of acidic It is made by mixing golden G and the rest of water.

[0047] Fatty acid sodium is selected from mixed oil fatty acid salt, which is obtained by mixing tallow and coconut oil in a certain proportion, and then undergoing saponification reaction or hydrolysis and neutralization. Sodium fatty acid and water are prepared according to a certain ratio to obtain soap particles. The ratio of fatty acid sodium salt and water can be controlled synergistically by the soap particles and the preparation process of the composition.

[0048] The production method and the processing conditions thereof of the essence soap composition containing capsules are as follows:

[0049] 1) Add the weighed soap particles into the mixing pot, stir for 2 minute...

Embodiment 3

[0055] A soap composition containing microcapsule essence, which is made of the following substances by weight percentage: 75 parts of sodium fatty acid, 0.5 part of tetrasodium edetate, 0.4 part of microcapsule essence, 0.7 part of stabilizer, It is made by mixing 0.01 part of acid golden yellow G and the rest of water.

[0056] Fatty acid sodium is selected from mixed oil fatty acid salt, which is obtained by mixing tallow and coconut oil in a certain proportion, and then undergoing saponification reaction or hydrolysis and neutralization. Sodium fatty acid and water are prepared according to a certain ratio to obtain soap particles. The ratio of fatty acid sodium salt and water can be controlled synergistically by the soap particles and the preparation process of the composition.

[0057] The production method and the processing conditions thereof of the essence soap composition containing capsules are as follows:

[0058] 1) Add the microcapsule essence to the stabilizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com