Preparation method of synbiotic

A technology of synbiotics and mulberry leaves, applied in the field of synbiotics, can solve the problems of high molecular weight and viscosity, non-degradable, low bioavailability, etc., and achieve the effect of fast growth rate, high activity, and simplified purification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add mulberry leaf powder to distilled water to obtain a 10% (w / v) solution, extract polysaccharides in water at pH 4.9 and 80°C for 8 hours, centrifuge at 5000×g for 5 minutes, take the supernatant, and concentrate to obtain Mulberry leaf polysaccharide solution;

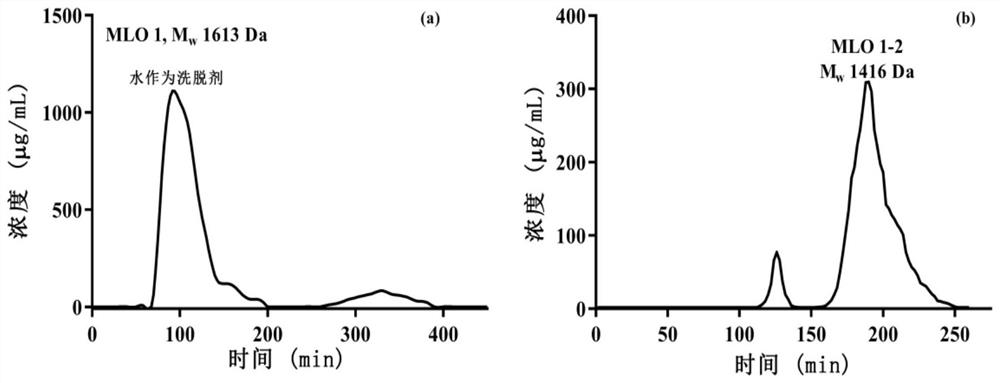

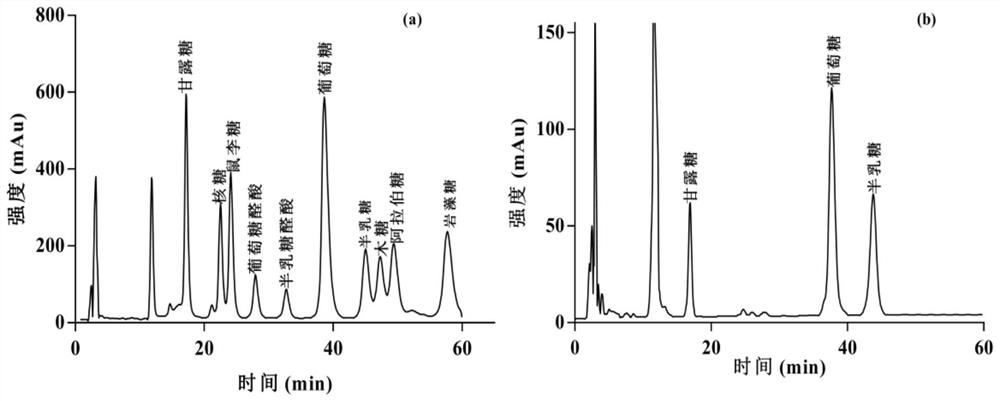

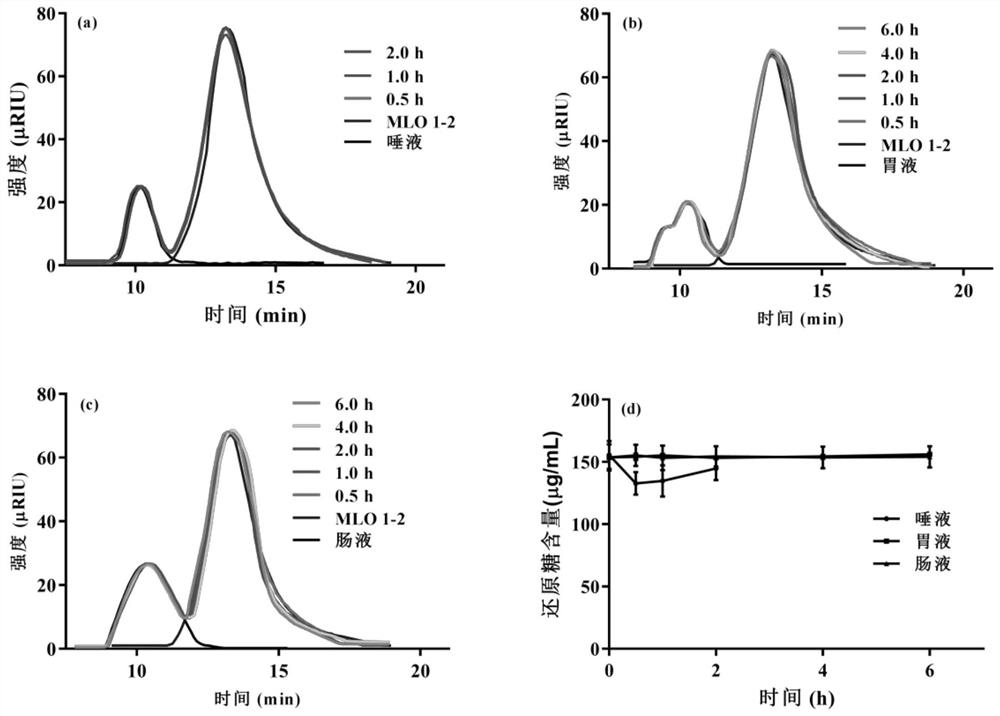

[0042] Take 3% mulberry leaf polysaccharide solution, add 1% hemicellulase, the reaction temperature is 50°C, the reaction time is 8h, the reaction pH is 6.0, and after centrifugation at 8000×g for 5min, the supernatant is taken and concentrated to obtain mulberry leaf oligosaccharides crude reaction solution;

[0043] The mulberry leaf oligosaccharide crude reaction solution is removed by combining nanofiltration (200Da) and ultrafiltration (2000Da) membrane systems to remove monosaccharides and polysaccharides that have not been degraded by enzymes and have a molecular weight greater than 2000Da in the oligosaccharide crude reaction solution to obtain Preliminary purified oligosaccharide solution;

[0044...

Embodiment 2

[0048] Add mulberry leaf powder to distilled water to obtain a 12.5% (w / v) solution, extract polysaccharides from water at pH 4.8 and 70°C for 7 hours, centrifuge at 5000×g for 5 minutes, take the supernatant, concentrate to obtain mulberry leaf polysaccharide solution;

[0049] Take 3.25% mulberry leaf polysaccharide solution, add 0.75% hemicellulase, the reaction temperature is 45°C, the reaction time is 7h, the reaction pH is 5.7, and after centrifugation at 8000×g for 5min, the supernatant is taken and concentrated to obtain mulberry leaf oligosaccharides crude reaction solution;

[0050] The mulberry leaf oligosaccharide crude reaction solution is removed by combining nanofiltration (200Da) and ultrafiltration (2000Da) membrane systems to remove monosaccharides and polysaccharides that have not been degraded by enzymes and have a molecular weight greater than 2000Da in the oligosaccharide crude reaction solution to obtain Preliminary purified oligosaccharide solution; ...

Embodiment 3

[0055] Add mulberry leaf powder to distilled water to obtain a 15% (w / v) solution, extract polysaccharides from water at pH 4.5 and 60°C for 6 hours, centrifuge at 5000×g for 5 minutes, take the supernatant, and concentrate to obtain Mulberry leaf polysaccharide solution;

[0056] Take 3.5% mulberry leaf polysaccharide solution, add 0.5% hemicellulase, the reaction temperature is 45°C, the reaction time is 6h, the reaction pH is 5.5, and the supernatant is taken by centrifugation at 8000×g for 5min, concentrated to obtain the crude mulberry leaf oligosaccharide The reaction solution;

[0057] The above-mentioned mulberry leaf oligosaccharide crude reaction solution is removed by combining nanofiltration (200Da) and ultrafiltration (2000Da) membrane systems to remove monosaccharides and polysaccharides that have not been degraded by enzymes and have a molecular weight greater than 2000Da in the oligosaccharide crude reaction solution, Obtain a preliminary purified oligosacchar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com