A kind of preparation method of pea peptide

A technology of pea peptide and pea, which is applied in the field of preparation of pea peptide, can solve the problems of high quality of neutral protease added, high amount of enzyme preparation, and low enzymatic hydrolysis efficiency, so as to achieve less enzyme consumption, lower bitterness value, and benefit The effect of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

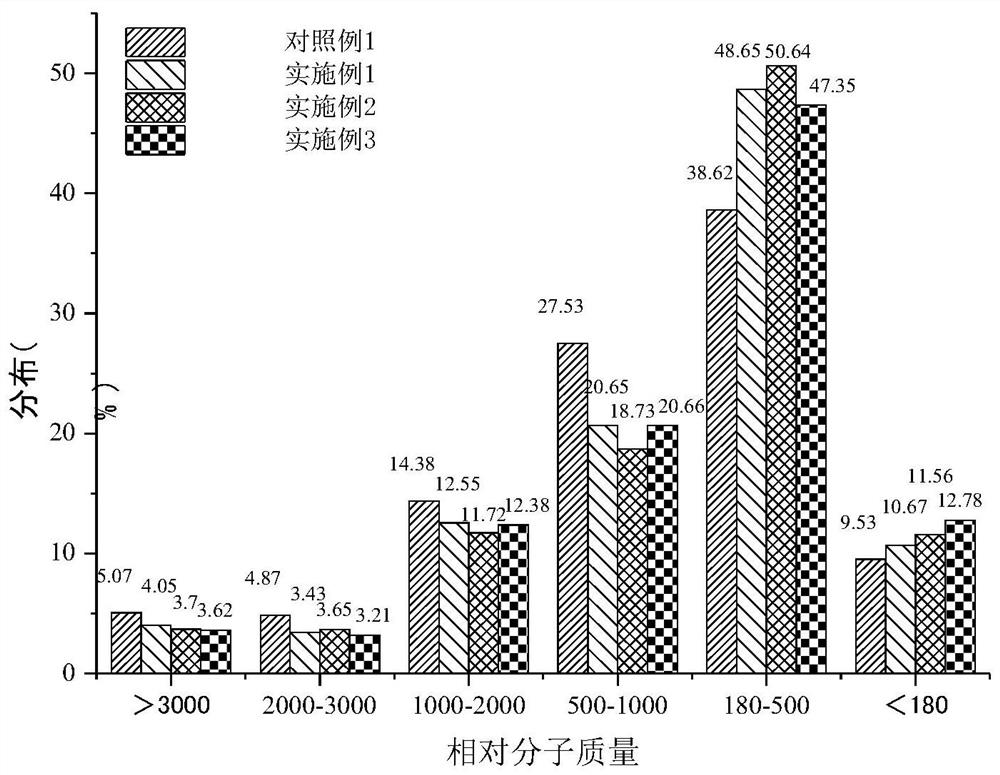

[0037] Example 1, using a method for preparing pea peptides proposed by the present invention with low bitterness, low enzyme consumption, and high peptide yield, the relative molecular mass distribution of pea peptide powder obtained by using this preparation method is as follows: figure 1 shown.

[0038] Specific steps are as follows:

[0039] Step A1: Use deionized water to make pea protein isolate powder into a mixture solution with a protein concentration of 5%, and stir evenly; transfer to step A2;

[0040] Step A2: Place the mixed material liquid in a high-pressure steam sterilizer, set the temperature at 100°C, and treat at a constant temperature for 20 minutes; turn to step A3;

[0041] Step A3: After cooling the heat-treated mixture to room temperature, add Alcalase (2160 U / g protein), the temperature is 55°C, adjust the pH value to 8.5 with 2mol / L NaOH, keep the pH constant, and the enzymatic hydrolysis time is 3h; then add protease P (120U / g protein), adjust the ...

Embodiment 2

[0044] Example 2, using a method for preparing pea peptides with low bitterness, low enzyme consumption and high peptide yield proposed by the present invention, the relative molecular mass distribution of pea peptide powder obtained by using this preparation method is as follows: figure 1 shown.

[0045] Specific steps are as follows:

[0046] Step B1: Use deionized water to make pea protein isolate powder into a mixture solution with a protein concentration of 5%, and stir evenly; transfer to step B2;

[0047] Step B2: Place the mixed material liquid in a high-pressure steam sterilizer, set the temperature at 121°C, and treat at a constant temperature for 20 minutes; turn to step B3;

[0048] Step B3: After cooling the heat-treated mixture to room temperature, add Alcalase (3000 U / g protein) at a temperature of 55°C, adjust the pH value to 8.5 with 2 mol / L NaOH, keep the pH constant, and the enzymatic hydrolysis time is 3h; then add protease P (120U / g protein), adjust the ...

Embodiment 3

[0051] Example 3, using a method for preparing pea peptide with low bitterness, low enzyme consumption and high peptide yield proposed by the present invention, the relative molecular mass distribution of pea peptide powder obtained by this preparation method is as follows: figure 1 shown.

[0052] Specific steps are as follows:

[0053] Step C1: Use deionized water to make pea protein isolate powder into a mixture solution with a protein concentration of 5%, and stir evenly; transfer to step C2;

[0054] Step C2: Place the mixed material liquid in a high-pressure steam sterilizer, set the temperature at 121°C, and treat at a constant temperature for 20 minutes; turn to step C3;

[0055] Step C3: After cooling the heat-treated mixture to room temperature, add Alcalase (2160 U / g protein) at a temperature of 55°C, adjust the pH value to 8.5 with 2 mol / L NaOH, keep the pH constant, and the enzymatic hydrolysis time is 3h; then add protease P (120U / g protein), adjust the pH valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com