Pipeline robot for oil-gas pipeline and pipeline defect detecting and repairing method

A pipeline robot, oil and gas pipeline technology, applied in the field of oil pipeline defect detection and repair, can solve problems such as difficulty in applying oil and gas transmission pipelines, and achieve the effect of ensuring the centering degree, overcoming the complexity of the structure and reducing the degree of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

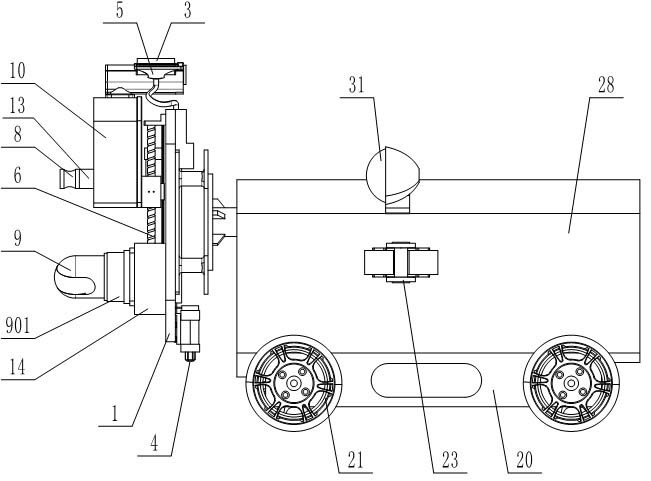

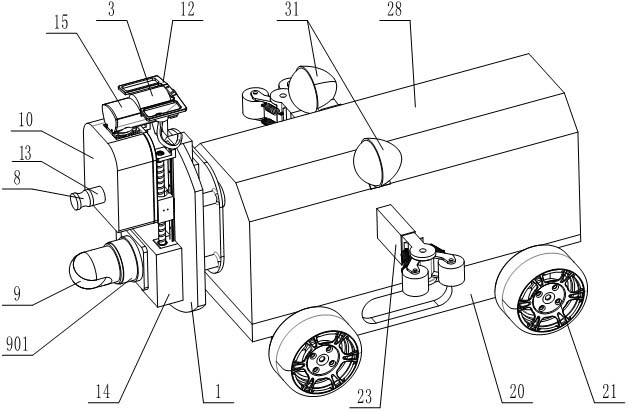

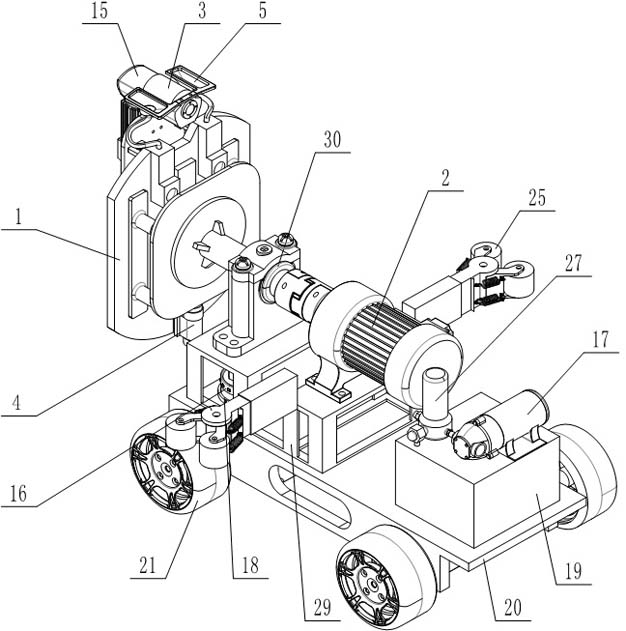

[0067] Such as Figure 1 to Figure 4 The shown pipeline robot for oil and gas pipelines includes a walking assembly and a working assembly connected to the walking assembly. The working assembly includes a rotating part 1, a defect detection device connected to the rotating part 1, and is used to drive the rotating part 1. The rotating first driving device 2, the grinding head 3 and the nozzle 4 that are slidably connected to the rotating part 1; the rotating part 1 is also provided with a dust suction device 5, a first induction device, and a second induction device, and the dust suction device 5 faces the grinding In the direction of the head 3, the first sensing device is used to sense the distance between the grinding head 3 and the pipe wall, and the second sensing device is used to sense the distance between the nozzle 4 and the pipe wall; the defect detection device includes an infrared detection device 8, an image acquisition device 9, Infrared detection device 8 is dr...

Embodiment 2

[0072] Such as Figure 1 to Figure 6 The shown pipeline robot for oil and gas pipelines, on the basis of Embodiment 1, the grinding head 3 is installed outside the first cover 10, and the grinding head 3 is driven by the fourth driving device 11 installed in the first cover 10 Drive to rotate, the second driving device 6 is used to drive the first cover 10 to move linearly as a whole; it also includes a positioning frame 12 fixed relatively to the first cover 10, and the positioning frame 12 includes a gap 121 for accommodating the grinding head 3 1. The dust suction jack 122 located on one side or both sides of the gap 121, the dust suction jack 122 is used to assemble the dust suction port of the dust suction device 5; the third driving device 7 passes through the second cover 14; the first cover 10. The second cover 14 is fixed on the side of the rotating part 1 away from the direction of the walking assembly; the image acquisition device 9 is installed on the platform 901,...

Embodiment 3

[0081] For the pipeline robot for oil and gas pipelines, on the basis of any of the above-mentioned embodiments, the walking assembly includes a car body 20, four wheels 21 distributed in a square shape for the car body 20 to walk, and each wheel 21 is composed of a sixth The driving device 22 is driven to rotate; the left and right sides of the walking assembly are provided with support arms 23, and the two support arms 23 are electric telescopic devices with synchronous actions; a third induction device is also included, and the third induction device is used for sensing the pipe wall to support The pressure exerted by the arm 23 and / or the distance between the support arm 23 and the pipe wall; the third sensing device and each sixth driving device 22 are all connected with the control system for signal. Wherein the sixth driving device 22 is preferably a DC motor, and the third sensing device can use a pressure sensor and a distance sensor at the same time.

[0082] In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com