Wafer alignment method in photoetching process

A lithography process and wafer technology, applied in photolithography, optics, sustainable manufacturing/processing and other directions on the pattern surface, can solve the problems of scrapped wafers, reduced wafer rotation ratio, increased wafer costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

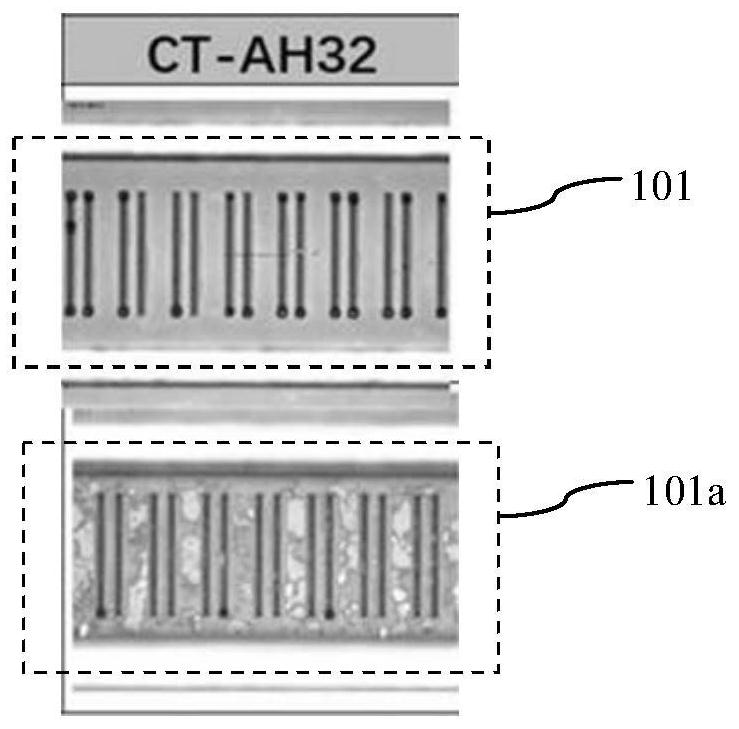

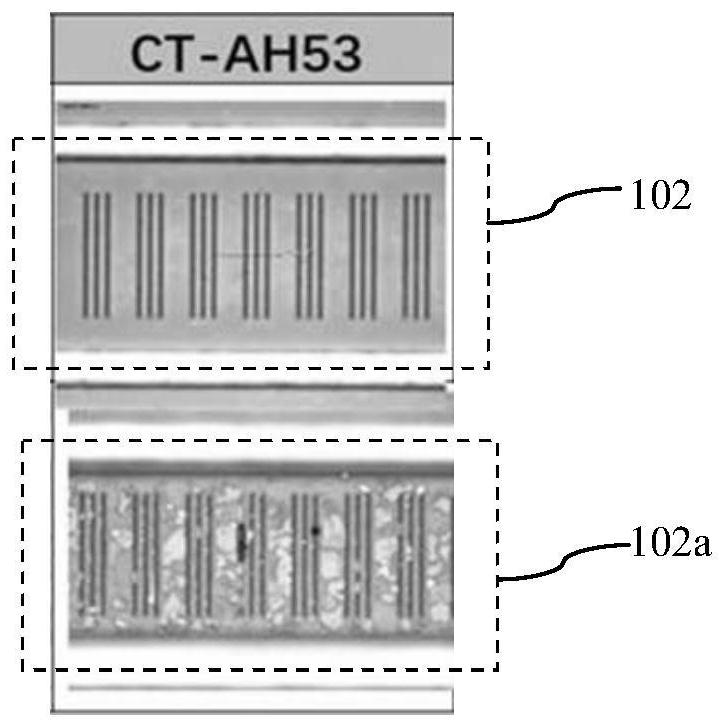

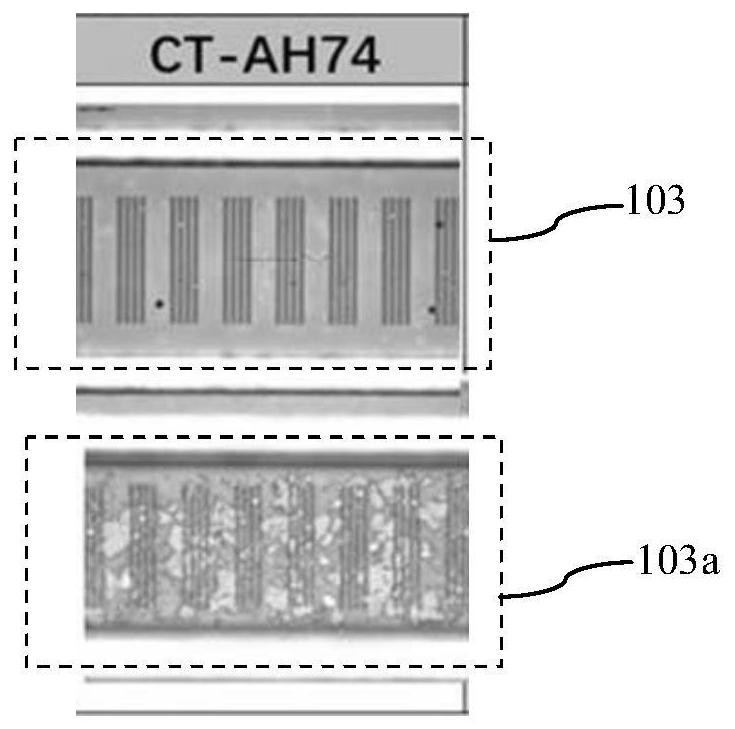

Image

Examples

Embodiment Construction

[0052] like image 3 Shown is the flow chart of the wafer alignment method in the photolithography process of the embodiment of the present invention; as Figure 5 Shown is the segmented alignment signal curve in the embodiment of the present invention; in the wafer alignment method in the photolithography process of the embodiment of the present invention, there is an alignment mark on the wafer, and the alignment mark has a grating pattern. The wafer alignment method includes the following steps:

[0053] Step 1: Use the alignment light source to scan the alignment mark in the entire section, and collect the diffracted light signal corresponding to the alignment mark in the entire section to form an alignment signal 1 in the entire section. Figure 5 Only a part of the whole alignment signal 1 is shown in .

[0054] Step 2, segmenting the whole segment of the alignment signal 1 to form each segmented alignment signal. Figure 5 Only three segmented alignment signals are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com