Methods for machining through holes and blind holes of multi-layer flexible board

A processing method and soft board technology, which is applied in the processing of insulating substrates/layers, circuit substrate materials, electrical components, etc., can solve problems such as inability to meet customer processing requirements, high water absorption, etc., and achieve good high temperature resistance and stable circuits reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

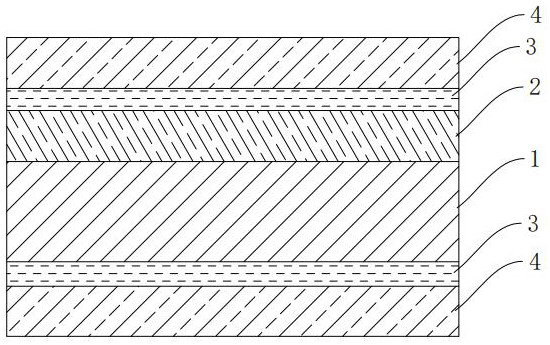

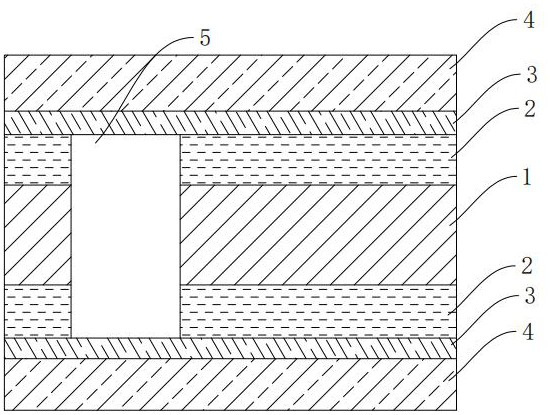

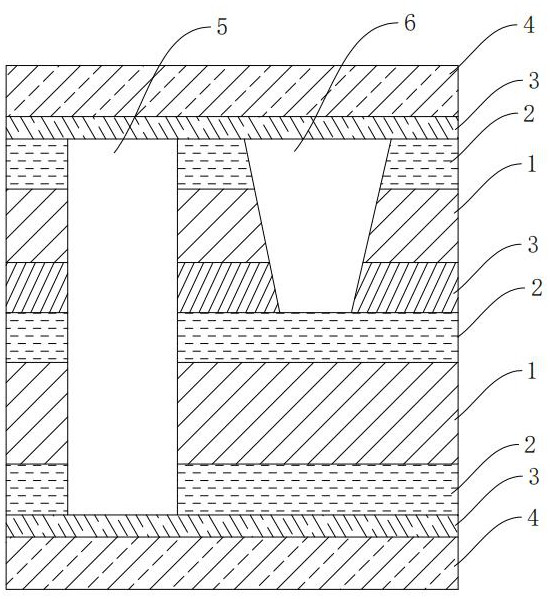

[0033] Embodiment one: see Figure 1~3 As shown, a method for making a soft board includes:

[0034] A substrate layer 1 made of PTFE material is provided with a copper layer 2 and processed to form a substrate with circuits;

[0035] The adhesive layer 3 and the outer layer board 4 are sequentially stacked outward from the side of the substrate and pressed together by a high-temperature pressing machine to form a soft board; wherein, the pressing temperature is 190°C-200°C, and the pressing time is 4h- 4.5h.

[0036] The Chinese name of PTFE is polytetrafluoroethylene, which is a high molecular polymer obtained by polymerization of tetrafluoroethylene as a monomer. PTFE has the characteristics of anti-acid, anti-alkali, and various organic solvents, and is almost insoluble in all solvents. At the same time, PTFE has the characteristics of high temperature resistance. Therefore, using the substrate layer 1 made of PTFE material, the copper layer 2 is placed on the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com