Process for dry fractionation to obtain final hard palm oil mid fraction

A technology of middle distillate and palm oil, which is applied in the field of ultrasonic-assisted dry fractionation, can solve the problem of low yield and achieve the effect of realizing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

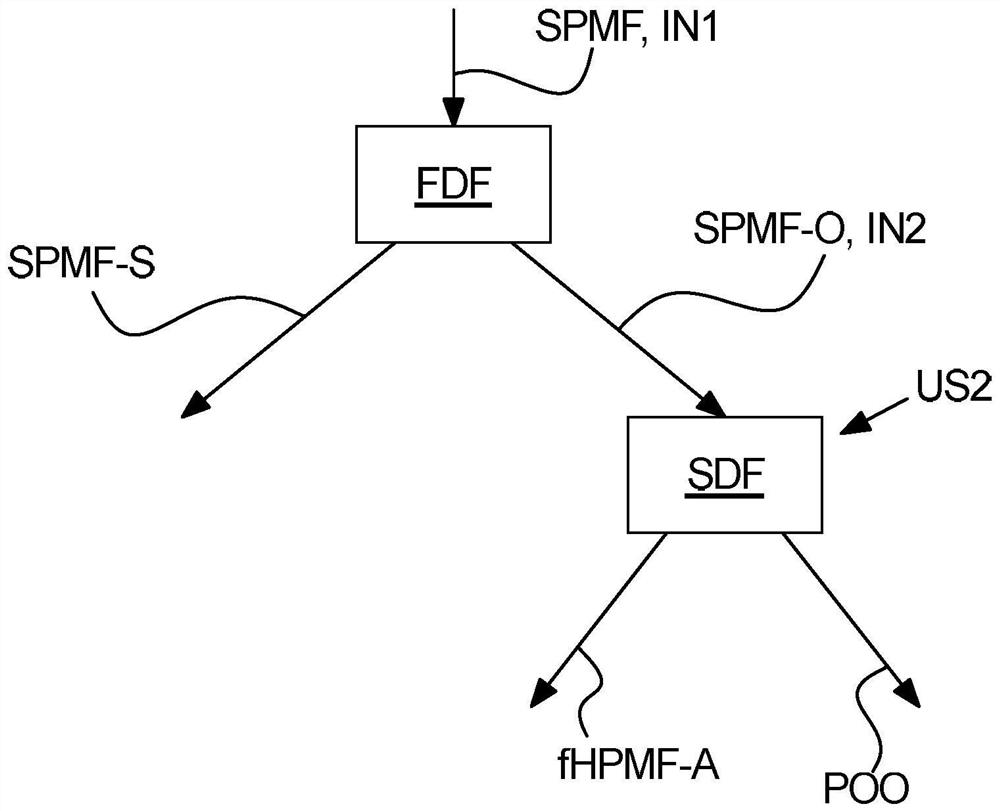

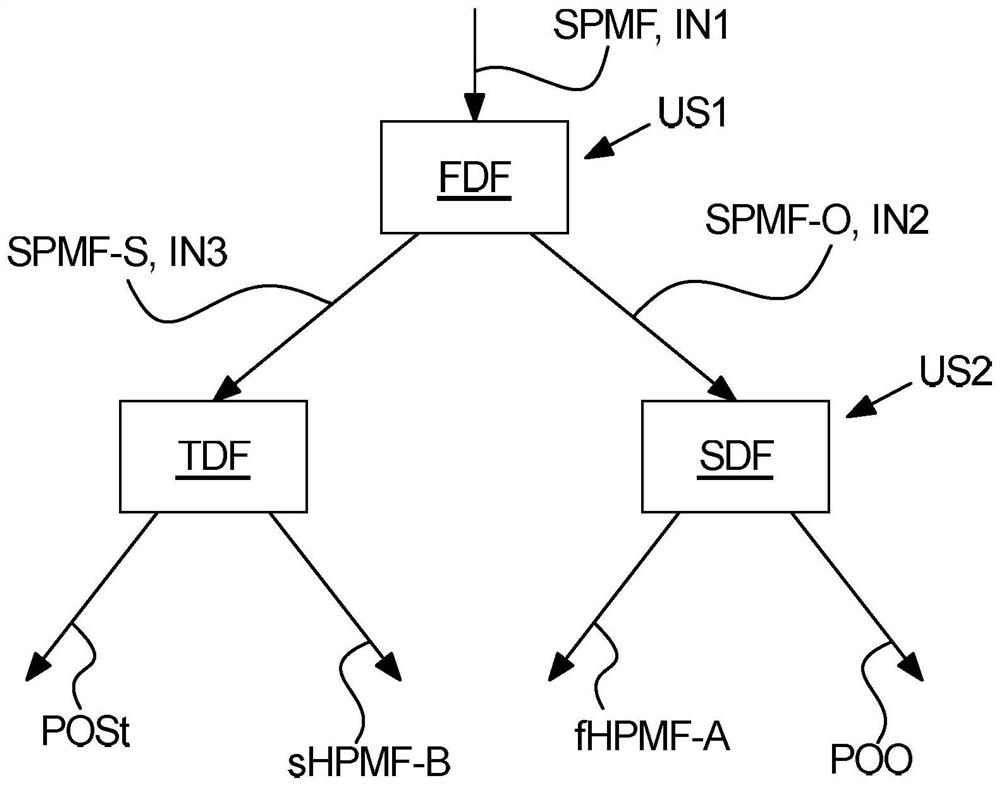

[0142] According to yet a further embodiment of the present invention, the process comprises a further prior dry fractionation (PDF) of palm olein (POO) to obtain soft palm oil middle fraction (SPMF) and super olein fraction (SOF ).

[0143] Advantageously, the further preceding dry fractionation may be an ultrasound assisted prior dry fractionation comprising sonication of at least a portion of the palm olein to obtain a soft palm oil middle and super olein fraction.

[0144] According to an embodiment of the present invention, the first melting step and the second melting step are performed by the same melting device.

[0145] According to a further embodiment of the invention, the first cooling step and the second cooling step are performed by the same cooling device.

[0146] According to yet a further embodiment of the present invention, the sonication (US1, US2) of the first and second dry fractionation (FDF, SDF) is performed by the same sonication device.

[0147] Ac...

Embodiment 1

[0215] Example 1 - Manufacture of Hard Palm Oil Middle Distillate

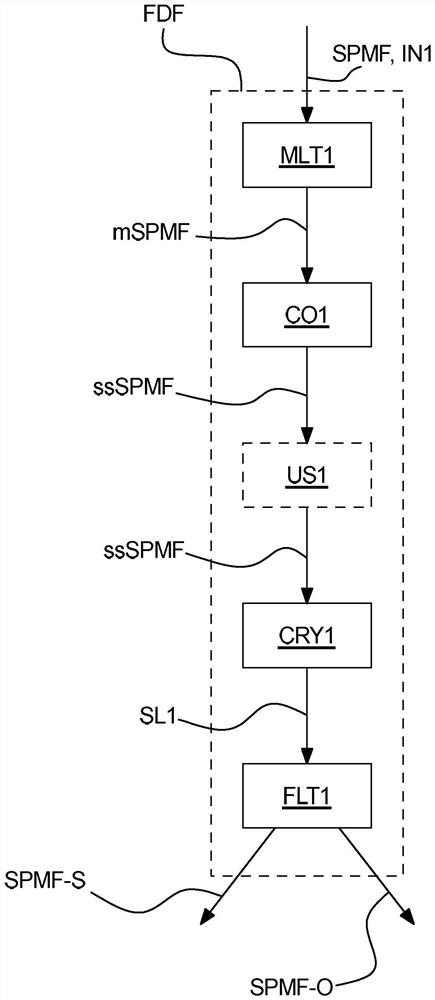

[0216] First, the soft palm oil middle distillate is heated to 60 degrees Celsius so that it is completely melted and held at this temperature for two hours.

[0217] The molten soft palm oil middle distillate is then gradually cooled to a temperature of 23 + / - 2 degrees Celsius over a period of two hours. The soft palm oil middle distillate was subjected to sonication at 23 degrees Celsius. Ultrasound was applied at an energy equivalent to 1000 Joules / liter of soft palm oil middle distillate. After reaching a temperature of 23 degrees Celsius, the soft palm oil middle distillate was kept at a constant temperature of 23 + / - 0.5 degrees Celsius for 18 hours.

[0218] After isothermal crystallization at 23 + / - 0.5 degrees Celsius for 18 hours, the soft palm oil middle fraction was filtered to obtain a middle olein fraction (SPMF-O) and a middle stearyl fraction (SPMF-S). A pressure of 25 bar was applied durin...

Embodiment 2

[0230] Example 2 - Compositions obtained and compositions based thereon

[0231] Table 2 shows the compositions of fat composition numbers 1-8 (composition numbers 1-8). The composition is obtained by simply mixing the ingredients. It can be seen that composition numbers 1-2 correspond to the final hard palm oil middle distillate (fHPMF-A) and the second hard palm oil middle distillate (sHPMF-B) obtained in Example 1.

[0232]

[0233] Table 2. Recipes for compositions (Comp.) no. 1-8 obtained using shea stearin, palm olein stearin (POSt) and hard palm oil middle distillates according to the invention (composition nos. 1-2). For composition numbers 6-8, the sum of the contents of fHPMF-A, sHPMF-B, shea stearin and POSt was 100%.

[0234] Palm Olein Stearin (POSt) was added to Composition Nos. 3-5, 8 to increase the PPP-triglyceride content.

[0235] Composition Nos. 6-8 included a substantial amount of hard palm oil middle distillate combined with shea stearin and thus r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com