A composite filter for smoke detection and its preparation method and application

A technology of smoke detection and filter, which is applied in the field of composite filter for smoke detection and its preparation, to achieve the effect of ensuring filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

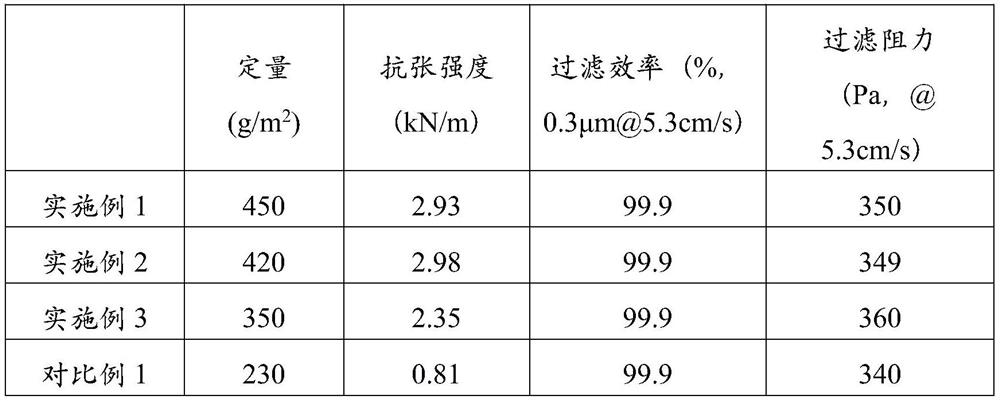

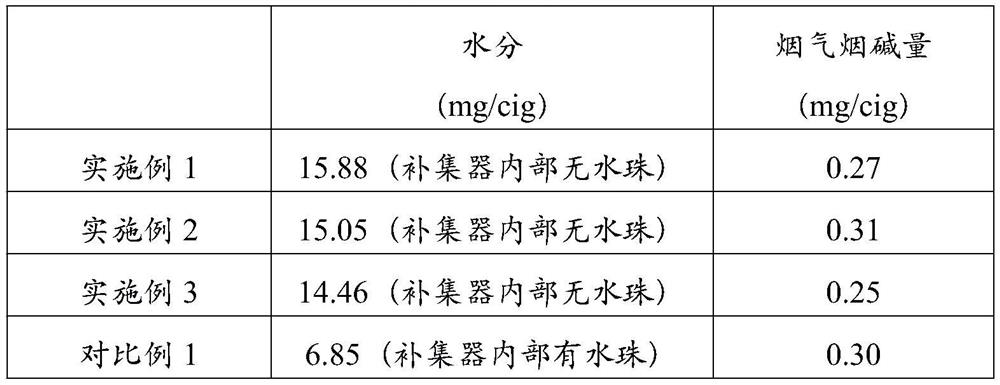

Examples

preparation example Construction

[0031] The present invention provides a method for preparing a composite filter for flue gas detection described in the above technical solution, comprising the following steps:

[0032] Mix the glass fiber and water, and carry out defrosting treatment to obtain the glass fiber slurry;

[0033] Mixing the glass fiber slurry, the first latex, the first reinforcement additive and the first defoamer to obtain a glass fiber mixed slurry;

[0034] Mixing the synthetic fiber and water, and performing a deflaking treatment, to obtain a synthetic fiber slurry;

[0035] Mixing the synthetic fiber slurry, the second dispersant and the second defoamer to obtain a synthetic fiber mixed slurry;

[0036] The glass fiber mixed slurry and the synthetic fiber mixed slurry are made to obtain a composite filter for smoke detection.

[0037] The invention mixes the glass fiber and water, and carries out defrosting treatment to obtain the glass fiber slurry. In the present invention, the compos...

Embodiment 1

[0049] (1) Glass fiber layer: quantitative 100g / m 2 . Mix 25 parts by weight of chopped glass fiber (15.0 μm in diameter and 3 mm in length) and 75 parts by weight of glass fiber cotton (34 ° SR) with water to obtain glass fiber slurry with a concentration of 2 wt %; The polyamide epichlorohydrin resin (calculated by dry weight) of 0.3 parts by weight is prepared as an aqueous solution of reinforcing agent, and the model of 0.07 parts by weight is the organosilicon defoamer (calculated by dry weight) of JF-05B. Foaming agent aqueous solution; 1 weight part of styrene-acrylic latex (calculated on a dry basis, purchased from Beijing Dongfang Chemical Factory) is formulated into latex aqueous solution; 0.5 weight part of polyethylene oxide is mixed with water to obtain dispersant aqueous solution;

[0050] After mixing the glass fiber slurry, reinforcing agent aqueous solution, defoamer aqueous solution, dispersant aqueous solution and latex aqueous solution, a glass fiber mixed...

Embodiment 2

[0055] (1) Glass fiber layer: quantitative 120g / m 2 . Mix 45 parts by weight of chopped glass fibers (15.0 μm in diameter, 3 mm in length) and 55 parts by weight of glass fiber cotton (44 ° SR) with water to obtain glass fiber slurry with a concentration of 2 wt %; The polyamide epichlorohydrin resin (calculated by absolute weight) of parts by weight is formulated as reinforcing agent aqueous solution, and the model of 0.07 parts by weight is the organosilicon defoamer (calculated by dry weight) of JF-05B Foaming agent aqueous solution; The styrene-butadiene latex of 1.5% weight portion (according to absolute dry weight, purchased from Dow Chemical) is formulated into latex aqueous solution;

[0056] After mixing the glass fiber slurry, reinforcing agent aqueous solution, defoamer aqueous solution and latex aqueous solution, a glass fiber mixed slurry with a mass concentration of 0.1% is obtained.

[0057] (2) Synthetic fiber layer: quantitative 300g / m 2 . 90 parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com