Thermal spraying, machining and detecting integrated device for motorcycle crankshaft

A thermal spraying and motorcycle technology, applied in metal material coating process, coating, manufacturing tools, etc., can solve the problem of high overall metal plating removal rate, increased workload of machine tools and operators, increased number of equipment and number of operators and Occupation area and other issues, to achieve the effect of saving electroplating metal and detection time, high accuracy and practicability, and green and environmentally friendly processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

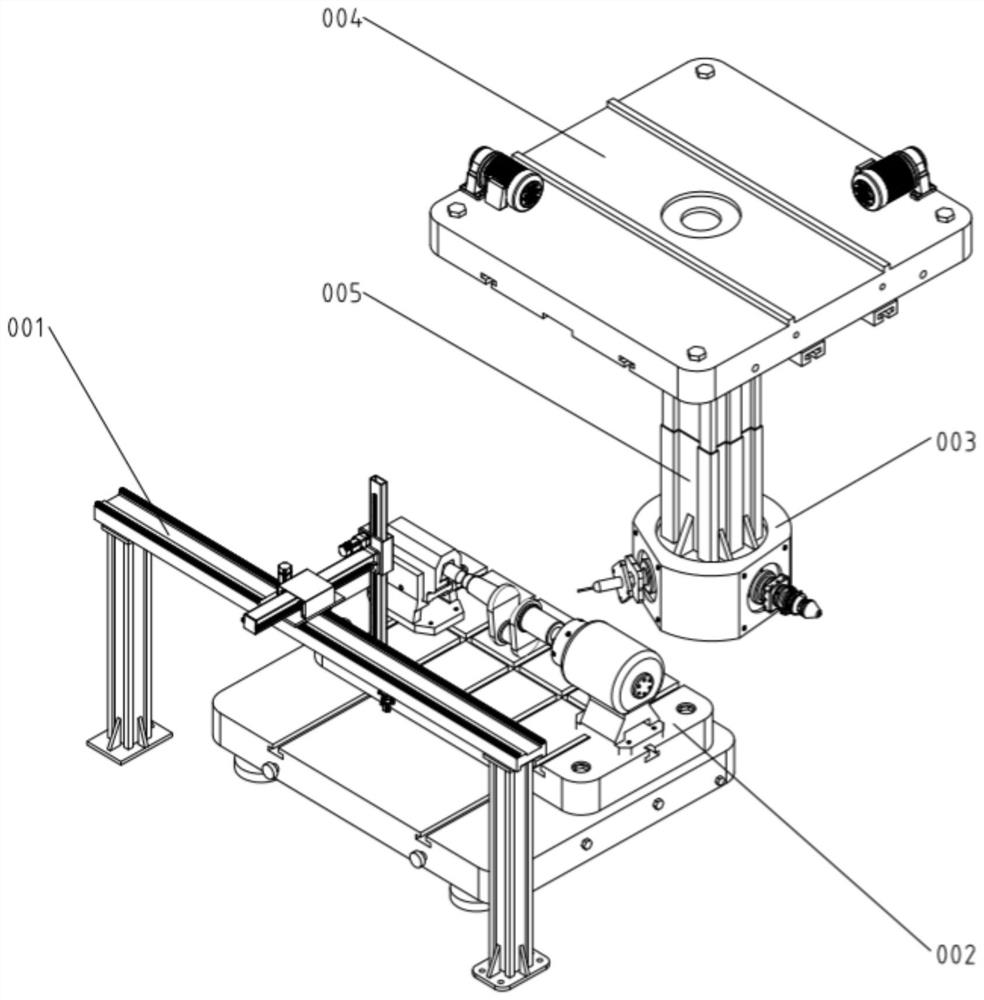

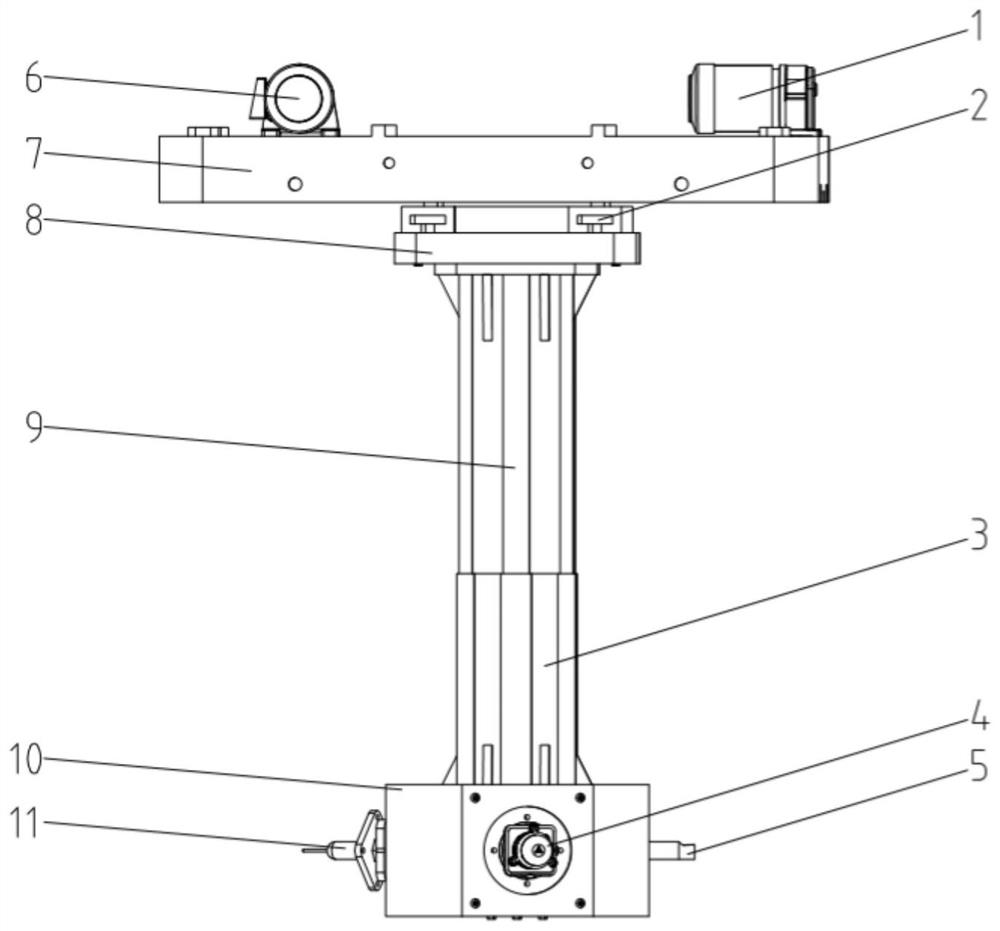

[0024] Such as Figure 1 to Figure 5 As shown, the thermal spraying, processing and testing integrated device for motorcycle crankshafts includes an automatic loading and unloading device 001, a workpiece clamping device 002, a composite rotary head device 003, a cross moving slide 004 and a servo electric Telescopic cylinder 005.

[0025] The automatic loading and unloading device 001 is a truss type manipulator.

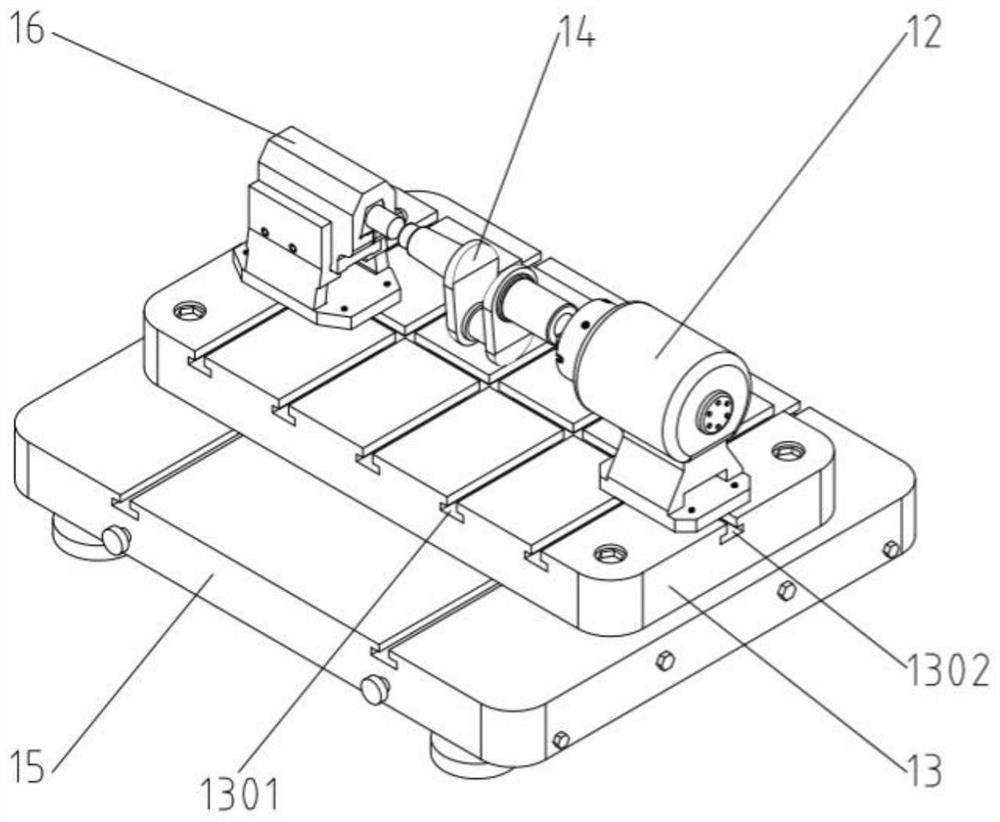

[0026] The workpiece clamping device 002 includes a three-jaw chuck 12, a movable top 16, a workbench 13 and a workbench base 15, the workbench 13 is slidably arranged on the workbench base 15, and the workbench 13 is fixed on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com