Molding container and packaging body for containing fat-containing food

A container and food technology, applied in household packaging, household containers, packaging, etc., can solve the problems of time-consuming and unpopular tableware cleaning, and achieve the effect of good blocking effect, compact crystal structure, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] Hereinafter, although an Example and a comparative example demonstrate this invention further, the technical scope of this invention is not limited to them.

[0094] The abbreviations used in the present examples have the following meanings.

[0095] Tmp (°C): melting point (JISK7121-1987)

[0096] ΔH (J / g): Crystal melting energy (JISK7122-1987)

[0097] TYS (MPa): Tensile Yield Stress (JIS K7127)

[0098] HPP1~3: Homopolypropylene

[0099] rPP: Poly(ethylene-propylene) random copolymer

[0100] bPP: Poly(ethylene-propylene) block copolymer

[0101] LLDPE: Linear Low Density Polyethylene

[0102] PET: polyethylene terephthalate

[0103] PU adhesive: Two-component curing polyester-polyurethane adhesive

[0104] The melting point (Tmp°C) and crystal melting energy (ΔH J / g) are measured values under the following conditions.

[0105] ・Measuring device: Differential Scanning Calorimeter DSC-60A, manufactured by Shimadzu Corporation

[0106] ·Sample size: 5mg

...

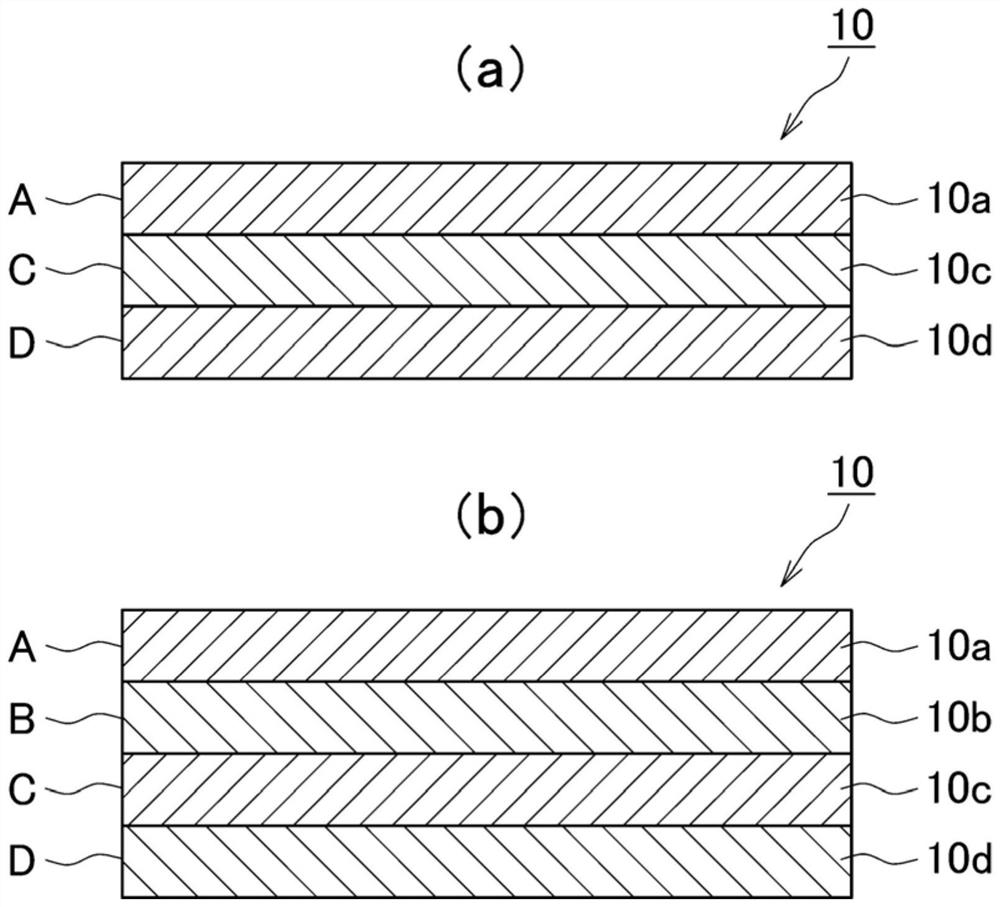

manufacture example 1

[0115] Both sides of a 120 μm thick aluminum foil (A8079H-O material) were treated with a chemical conversion treatment solution containing phosphoric acid, acrylic resin, chromium (III) salt compound, water, and alcohol to prepare a treated aluminum foil with a base layer formed thereon. It should be noted that the amount of chromium attached to each side is 10mg / m 2 . Next, a PU adhesive was applied to one side of the treated aluminum foil so that the dry film thickness became 3 μm, and a film formed of HPP1 (300 μm thick, manufactured by T-die method) was bonded. Next, apply a PU adhesive on the other side of the treated aluminum foil so that the dry film thickness becomes 3 μm, and attach a total of 30 μm including a 4.5 μm thick rPP layer, a 21 μm thick bPP layer, and a 4.5 μm thick rPP layer. A thick unstretched three-layer coextruded polyolefin film from which a laminate is made. Next, this laminated body was aged at 40 degreeC for 8 days, and the aluminum laminated p...

manufacture example 2~3

[0117] In the same manner as in Production Example 1, except that a film formed of HPP2 (300 μm thick, produced by T-die method) or a film formed of HPP3 (300 μm thick, produced by T-die method) was used instead of the film formed of HPP1 Operation, making aluminum laminate packaging materials B and C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com