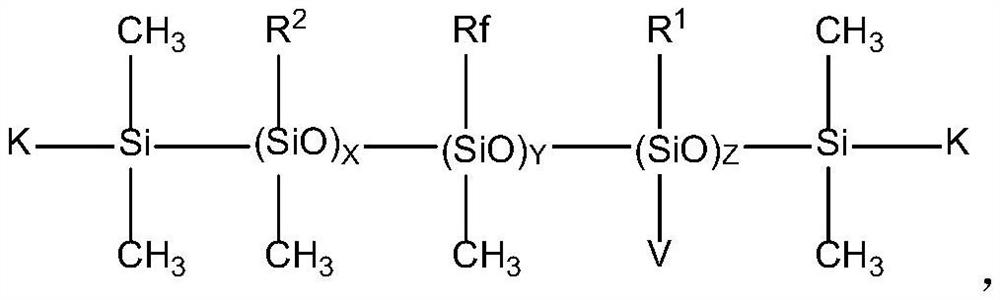

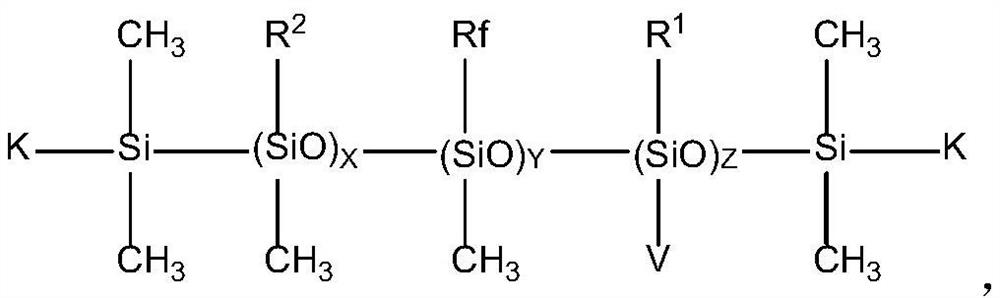

Linear organic fluorine-containing polysiloxane as well as preparation method and application thereof

A polysiloxane and organic technology, which is applied in the field of linear organic fluorine-containing polysiloxane and its preparation, can solve the problems of high cost and viscosity control of fluorine-containing polysiloxane, and achieves less by-products and convenient post-processing. , the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 100 parts by weight of fluorine-containing monomer C 3 f 7 C(CF 3 ) 2 CH 2 CH 2 Si(Cl) 2 CH 3 After hydrolysis treatment, with 4.86 parts by weight of hexamethylhexavinyl cyclohexasiloxane 110.51 parts by weight of hexamethylcyclotrisiloxane 0.213 parts by weight of silane end-capping agent After mixing, add it to the reaction kettle, protect it with nitrogen, raise the temperature to 80°C, add trifluoromethanesulfonic acid with a mass fraction of 0.3% fluorine-containing monomer, and catalyze the reaction for 10 hours, then lower the temperature, neutralize, filter, and remove low boilers to obtain Fluorine-containing polysiloxane with a fluorine content of 33 wt%, a vinyl content of 1.2 wt%, and a viscosity of 330 mPa·s has a yield of 89.1%.

Embodiment 2

[0034] 100 parts by weight of fluorine-containing monomer C 3 f 7 C(CF 3 ) 2 CH 2 CH 2 CH 2 CH 2 Si(Cl) 2 CH 3 After hydrolysis treatment, with 18.4 parts by weight of trimethylcyclotrisiloxane 83.4 parts by weight of hexamethylcyclotrisiloxane 0.201 parts by weight of silane end-capping agent After mixing, add it to the reaction kettle, protect it with nitrogen, raise the temperature to 80°C, add trifluoromethanesulfonic acid with a mass fraction of 0.3% fluorine-containing monomer, and catalyze the reaction for 10 hours, then lower the temperature, neutralize, filter, and remove low boilers to obtain Fluorine-containing polysiloxane with a fluorine content of 32.4 wt%, a hydrogen content of 16.3 wt%, and a viscosity of 280 mPa·s has a yield of 90.3%.

Embodiment 3

[0036] 100 parts of fluorine-containing monomer C 3 f 7 C(CF 3 ) 2 OCOCH 2 CH 2 Si(Cl) 2 CH 3 After hydrolysis treatment, with 2.56 parts by weight of hexamethylhexavinyl cyclohexasiloxane 52.31 parts by weight of hexamethylcyclotrisiloxane 0.146 parts by weight of silane end-capping agent After mixing, add it to the reaction kettle, protect it with nitrogen, raise the temperature to 80°C, add trifluoromethanesulfonic acid with a mass fraction of 0.3% fluorine-containing monomer, and after catalyzing the reaction for 10 hours, lower the temperature, neutralize, filter, and remove low boilers to obtain Fluorine-containing polysiloxane with a fluorine content of 42.5 wt%, a vinyl content of 2.1 wt%, and a viscosity of 480 mPa·s has a yield of 92.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com