Water drive logging device

A well logging and water flooding technology, applied in the direction of measurement, borehole/well components, and production fluid, etc., can solve problems affecting construction efficiency, large lifting resistance, and complicated control mechanism, so as to improve construction production efficiency and reduce Lift up the resistance and expand the effect of the use scene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

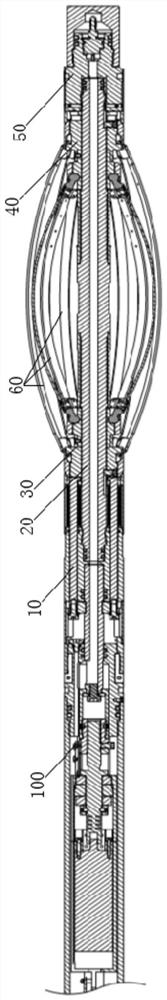

[0043] See figure 1 , a water flooding logging device, comprising: a Hall element 100 , a driving assembly 10 , a central rod 20 , a first connection assembly 30 , a second connection assembly 40 , a fixed sleeve 50 and a plurality of metal strip assemblies 60 . The Hall element 100 is arranged on the driving assembly 10 , and the Hall element 100 is used for sending the working signal of the driving assembly 10 . The working signal can control the shutdown of the driving motor 11 of the driving assembly 10 . The driving assembly 10 is connected with one end of the central rod 20 and the first connecting assembly 30 , and the driving assembly 10 is used to drive the first connecting assembly 30 to slide axially on the central rod 20 . The first connection assembly 30 is sheathed on the center rod 20 , and the first connection assembly 30 is slidably connected with the center rod 20 . In this embodiment, the driving assembly 10 can drive the first connecting assembly 30 to sl...

Embodiment 2

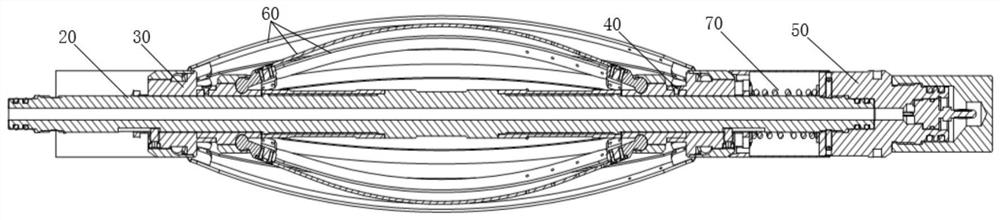

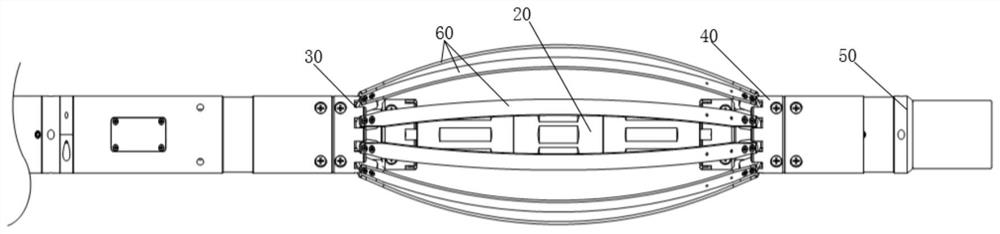

[0057] Such as figure 2 and Figure 4 As shown, this embodiment is based on the first embodiment and further defines a layer structure in which a plurality of metal strip assemblies 60 are surrounded by multiple layers. A plurality of metal strip assemblies 60 may form a multi-layer structure. A plurality of metal strip assemblies 60 of each layer are sequentially arranged around the circumferential direction of the central rod 20 . The first connection assembly 30 includes a plurality of first sliding sleeves 31 . The second connection assembly 40 includes a plurality of second sliding sleeves 41 . The metal strip assembly 60 of each layer is connected with a first sliding sleeve 31 and a second sliding sleeve 41 . In the structure of one layer, a first sliding sleeve 31 is connected to one end of multiple metal strip assemblies 60 , and a second sliding sleeve 41 is connected to the other ends of multiple metal strip assemblies 60 . A plurality of first sliding sleeves...

Embodiment 3

[0076] Such as Figure 12 As shown, this embodiment is based on the first or second embodiment and further defines that the drive assembly 10 includes: a drive motor 11 , a lead screw 12 , a nut sleeve 13 , a push-pull assembly 14 and a housing 15 . The casing 15 is all tubular, or partly tubular, partly columnar. It can also be an integral shell structure, or can be composed of multi-section shells 15 . The shell of the driving motor 11 is fixedly connected with one end of the housing 15 . The output shaft of the driving motor 11 is fixedly connected with one end of the lead screw 12 . The screw 12 extends along the axial direction of the central rod 20 , and the screw 12 is located in the housing 15 . The nut sleeve 13 is threadedly connected with the lead screw 12 , and the nut sleeve 13 is slidably connected with the housing 15 through the stopper 16 , and the end of the nut sleeve 13 away from the driving motor 11 is connected with the push-pull assembly 14 . The limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com