Acid fracturing method

A technology of acid fracturing and fracturing, which is applied in the field of oil or shale gas exploitation. It can solve problems such as difficult rock surface morphology, rapid collapse of protrusions, and decreased conductivity, so as to reduce temperature, increase the length of acid-etched fractures, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

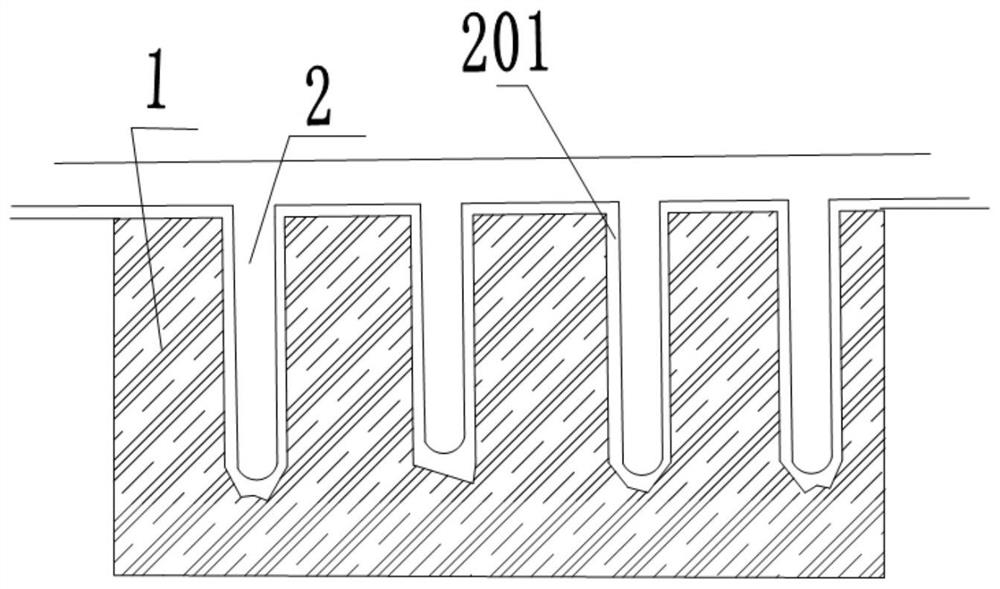

[0059] Acid fracturing is performed through the following process:

[0060] (1) Evaluation of key reservoir parameters

[0061] Including physical properties, rock mechanical parameters, three-dimensional in-situ stress, development of natural fractures, etc., methods such as seismic, well logging, mud logging, and pilot well core laboratory testing and analysis can be used.

[0062] (2) Determination of well completion method

[0063] If the open hole completion method is used to complete the well, the open hole sliding sleeve segmental fracturing method can be used, or the casing completion method can be used, and the bridge plug perforation technology can be used for segmental fracturing construction.

[0064] (3) Optimization of fracture parameters

[0065] On the basis of geological modeling in step (1), use commercial software such as ECLIPSE, which has the simulation function of acid fracturing with dual-media or triple-media simulation function, to set artificial fra...

Embodiment 2

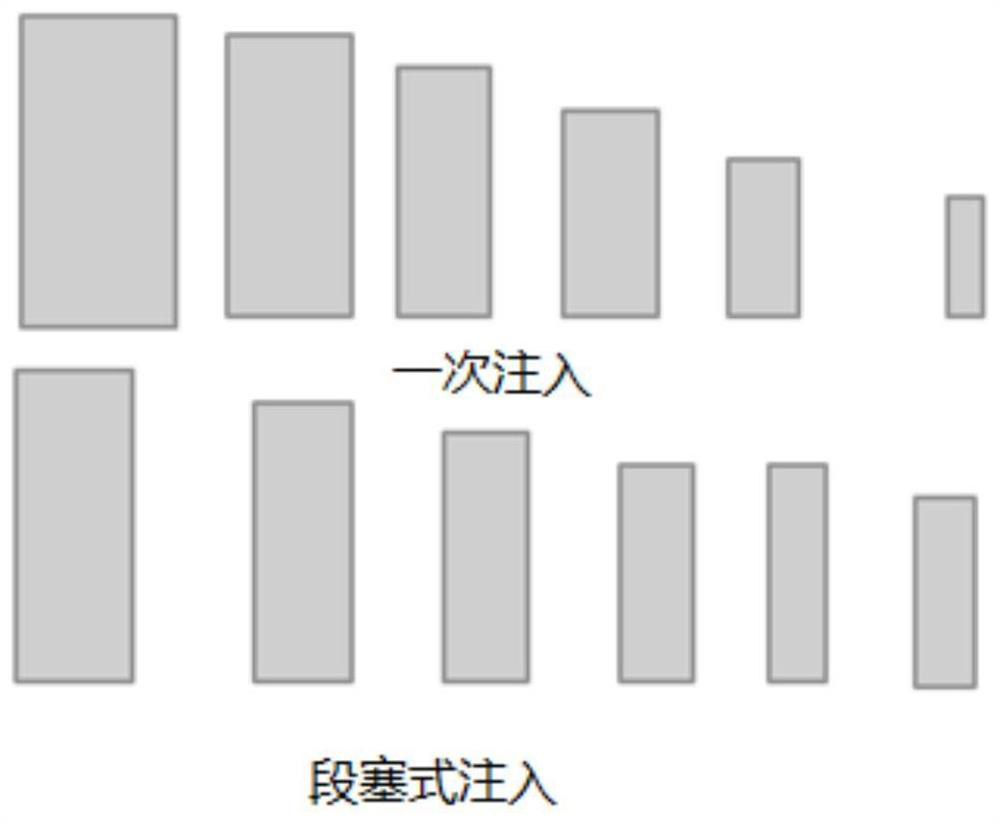

[0085] A deep carbonate reservoir in the Tarim Basin was exploited by using the acidizing fracturing process as in Example 1. The well depth of the carbonate reservoir is 6,500 meters. 3 / min displacement injection 240m 3 The viscosity of the fracturing fluid is 100mPa.s, and then the fracturing fluid is 3m 3 / min displacement, use 1-3mPa.s slick water to carry 40-60 purpose shielding and protecting agent into 3 slugs, and the injection concentration of shielding and protecting agent is 200-500kg / m 3 , the displacement of the injected displacement fluid is 6m 3 / min, the displacement fluid used is slick water. The total liquid volume of the shielding agent is 4m 3 , the replacement fluid volume is 4m 3 , alternately for 3 times, after the construction of this stage, stop the pump for 15 minutes. Then sequentially use 3m 3 / min displacement injection 10mPa.s acid 60m 3 , 4m 3 / min displacement injection 30mPa.s acid liquid 60m 3 , 6m 3 / min displacement injection 50m...

Embodiment 3

[0088] The acid fracturing process as in Example 1 is used to exploit a certain deep carbonate reservoir. The well depth is 7480 meters. 3 / min displacement injection 300m 3 Fracturing fluid with a viscosity of 100mPa.s, and then 8m 3 / min of displacement with slippery water to carry 40-60 mesh first shielding agent and inject 3 slugs. The injection concentration of the first shielding agent is 400kg / m 3 , carried by slick water with a viscosity of 3mPa.s, the replacement fluid is the same slick water, and the total liquid volume at this stage is 42m 3 , where the first slug, carrying fluid is 5m 3 , the replacement fluid is 5m 3 ;Second slug with 6m of carrier fluid 3 , the replacement fluid is 8m 3 ; the third slug, the carrier fluid is 8m 3 , the displacement fluid is 10m 3 ; equal time intervals between each slug. After the construction at this stage, stop the pump for 20 minutes.

[0089] Then sequentially use 4m 3 / min displacement injection 15mPa.s acid solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com