A guidance method for steam soot blowing optimization of boiler air preheater

An air preheater and steam technology, which is applied in combustion methods, indirect carbon dioxide emission reduction, clean heat transfer devices, etc., can solve the problem that steam soot blowing cannot function effectively, the evolution period of ash accumulation is shortened, and the resistance of air preheater increases, etc. problems, to achieve the effect of ensuring economic and safe operation, preventing agglomeration and scaling, and putting into operation a reasonable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Such as figure 2 As shown, a boiler air preheater steam soot blowing optimization guidance method includes the following steps:

[0041] Calculate the ammonium bisulfate deposition coefficient according to the flue gas parameters, and evaluate the adhesion and deposition tendency of ammonium bisulfate in the air preheater;

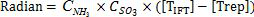

[0042] The ammonium bisulfate deposition coefficient is calculated in real time based on unit monitoring data, and the parameters with poor measurement accuracy are obtained through theoretical calculation;

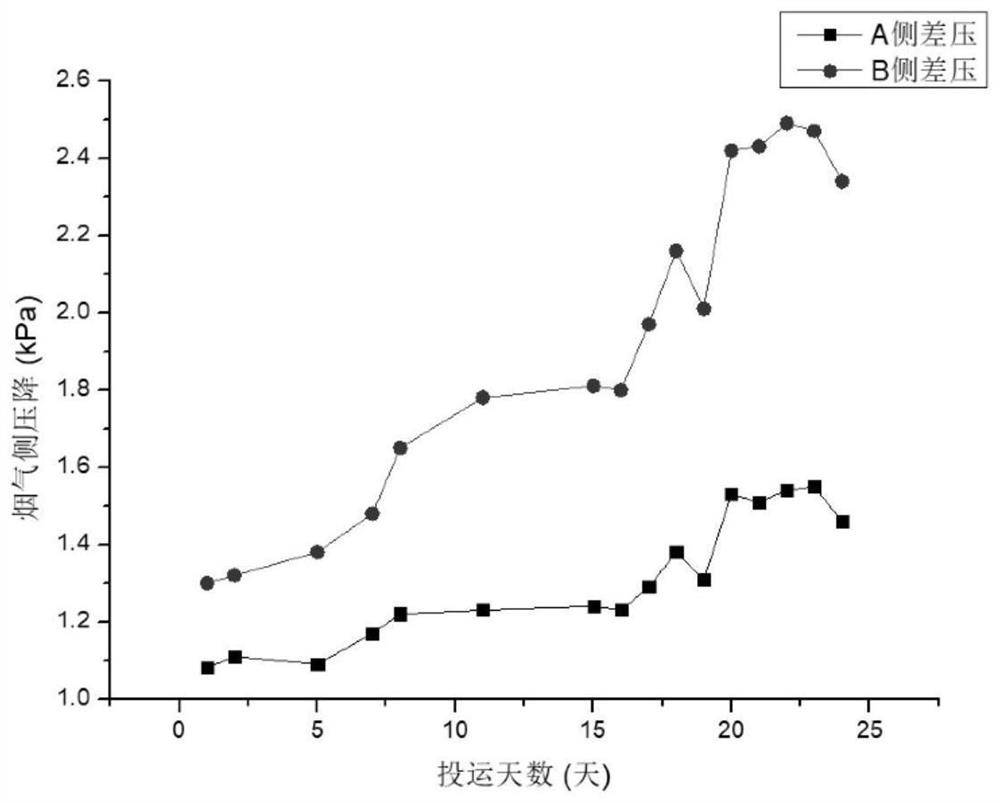

[0043] According to the side pressure drop of the flue gas of the air preheater and the boiler load operation data, the drag coefficient of the flue gas of the air preheater is calculated to reflect the dust accumulation and blockage of the air preheater;

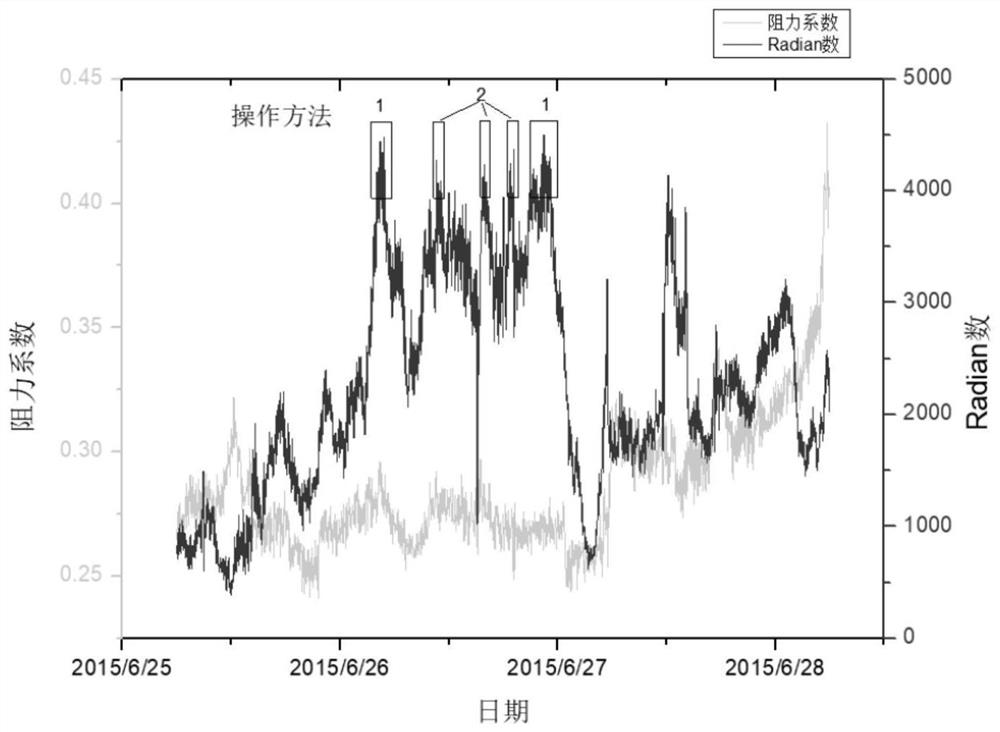

[0044] Obtain the correlation between the air preheater flue gas resistance coefficient and the ammonium bisulfate deposition coefficient, use the ammonium bisulfate deposition coefficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com