Micro-system packaging shell with heterogeneous integrated double-sided cavity structure and manufacturing method

A technology of encapsulating shell and cavity structure, which is used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., to achieve the effect of taking into account heat dissipation and weight constraints, meeting high reliability and excellent transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

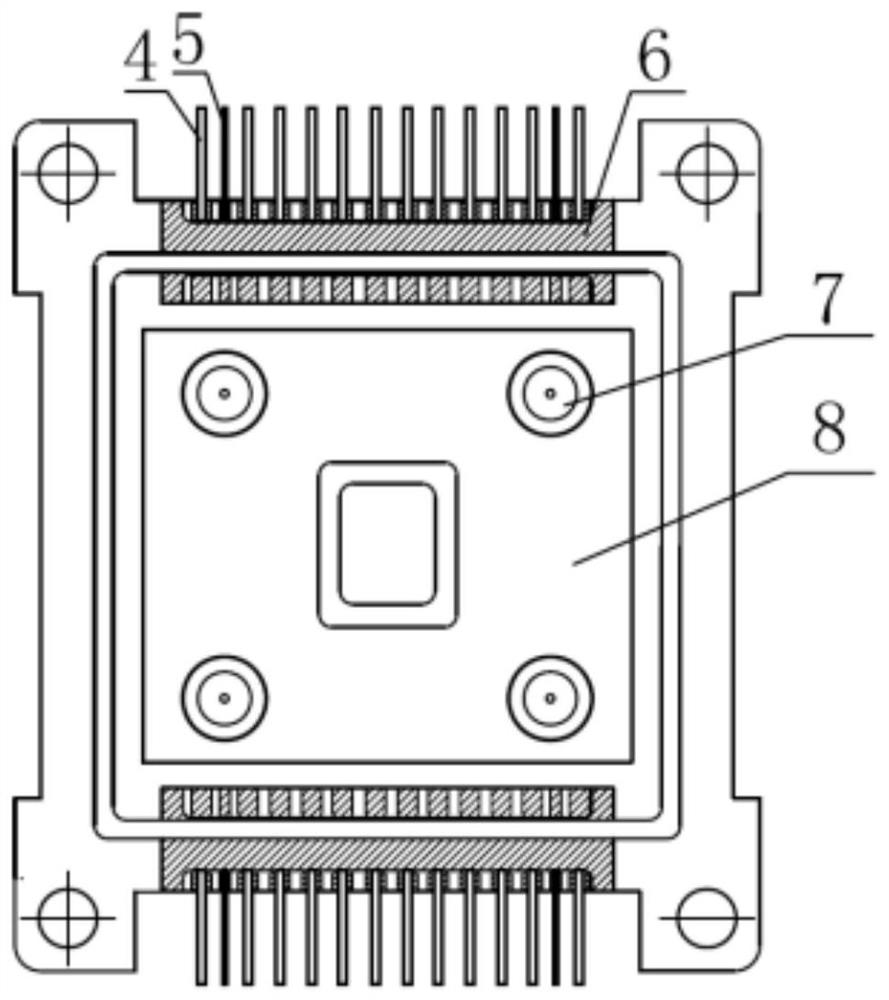

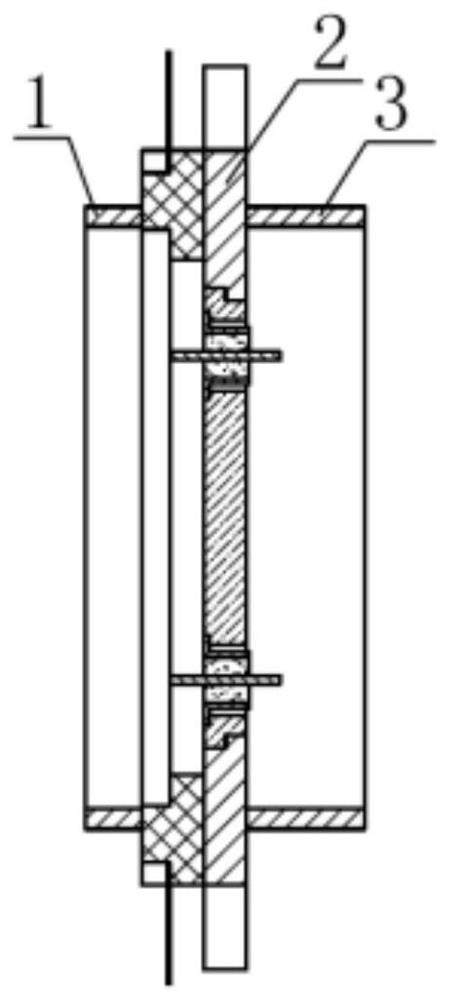

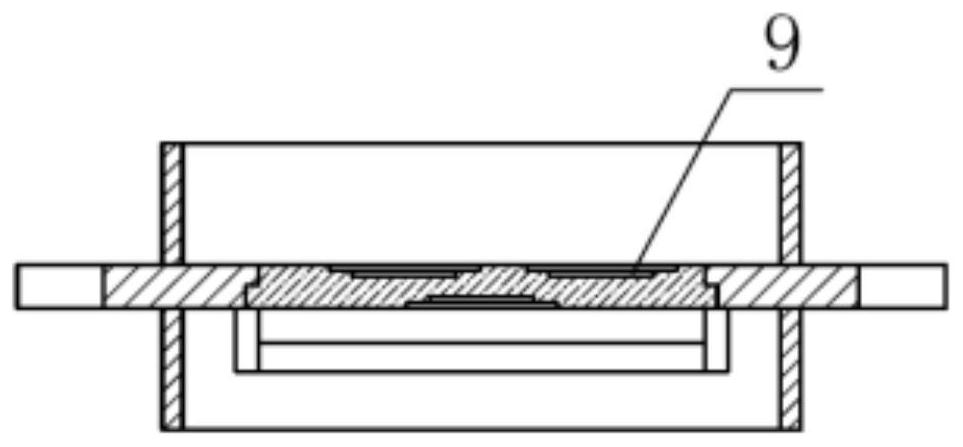

[0049] The present invention aims to provide a heterogeneous integrated double-sided cavity structure microsystem packaging shell with many types of output terminals, double-sided cavity structure, good heat dissipation, and high reliability. figure 2 It can be seen from the side view that the shell is in the form of a double-sided cavity metal shell, which can work in the DC-40GHz frequency band, that is, a metal bottom plate 2 is installed in the middle of the shell body to form a double-sided cavity structure, and the upper metal Frame 1 and the lower metal frame, the metal bottom plate is made of tungsten copper or molybdenum copper material, the upper me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com