SMD type passive electronic component mounting structure and method

A technology for electronic components and mounting structures, which is applied in the field of patch-type passive electronic component mounting structures and methods, can solve problems such as void layering, short circuit of component terminals, and inability to adhere to chips, so as to eliminate gaps, improve precision and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

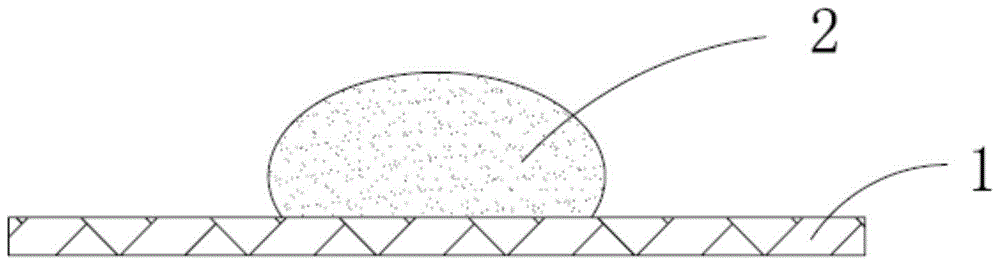

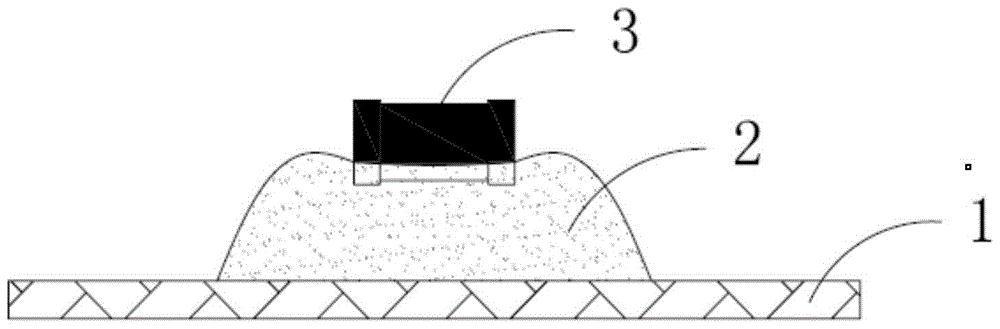

[0036] Below, refer to Figure 1A , Figure 1B and figure 2 The installation structure according to the first embodiment of the present invention is explained, wherein Figure 1A and Figure 1B is a schematic diagram of the mounting structure at different stages of fabrication, figure 2 It is a top view of the installation structure. The first embodiment of the present invention is a mounting structure in which a chip thermistor 3 is mounted on a substrate 1 as a passive electronic component.

[0037] Such as Figure 1A As shown, a substrate 1 is provided as a carrier part, and a high thermal conductivity insulating glue 2 is first dotted on the substrate 1, and then, as shown in FIG. Figure 1B As shown in , paste the chip thermistor 3 on the high thermal conductivity insulating glue 2, and fix the insulating glue 2. The amount of glue dispensing can be set according to the size of the chip thermistor 3. It is best that the high thermal conductivity insulating glue 2...

no. 2 example

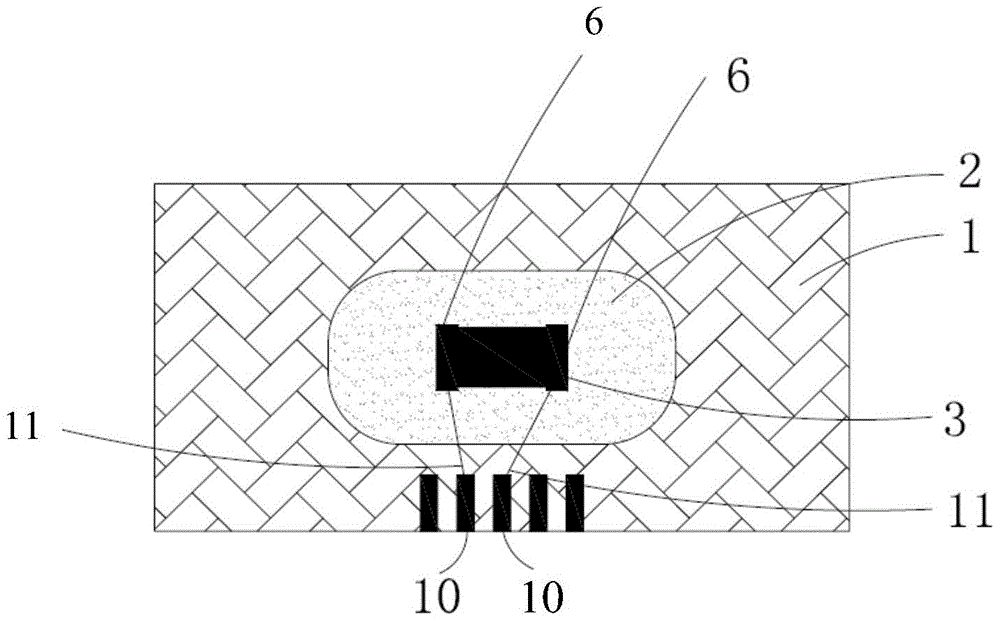

[0044] image 3 A schematic diagram showing a mounting structure according to a second embodiment of the present invention. The difference from the first embodiment is that an electronic component 4 as a carrier part is added in the mounting structure of the second embodiment, and the electronic component 4 can be an active electronic component, such as an integrated circuit chip, or another A surface mount passive electronic component such as a resistor, inductor or capacitor. One surface of the electronic component 4 as the carrier part is pasted on the substrate 1 by insulating glue 7, and the chip type thermistor 3 is pasted on the other surface of the electronic component 4 as the carrier part by the high thermal conductivity insulating glue 2, usually On the upper surface of the second electronic component 4 .

[0045] In addition, the mounting structure of the second embodiment also includes bonding wires 11 for electrical connection. Specifically, the mounting struc...

no. 3 example

[0051] Figure 4 A schematic diagram of a mounting structure according to a third embodiment of the present invention is shown. The mounting structure of the third embodiment uses the integrated circuit chip 5 as the carrier part of the chip thermistor 3 . In particular, here the integrated circuit chip 5 is configured to have a groove 20 , and the chip thermistor 3 is fixed in the groove 20 by the high thermal conductivity insulating glue 2 . The groove 20 can be formed in the integrated circuit chip 5 by an etching method. Preferably, the depth of the groove 20 can be set to be larger than the height of the thermistor 3, so that the thermistor 3 is completely accommodated in the groove 20 and It does not protrude from the upper surface of the integrated circuit chip 5 . Two terminals 6 of the thermistor 3 are connected to pads 12 as terminals on the integrated circuit chip 5 through bonding wires 11 .

[0052] The installation method of the installation structure of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com