Production method of green high-quality instant noodles

A production method and instant noodle technology, applied in the direction of food science, etc., can solve the problems of instant noodles affecting consumers' eating experience, high energy consumption of production process, and unfavorable consumers' health, so as to improve physical health, save layout space, and improve product quality and productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

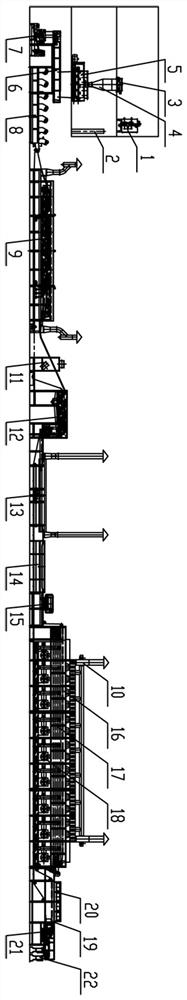

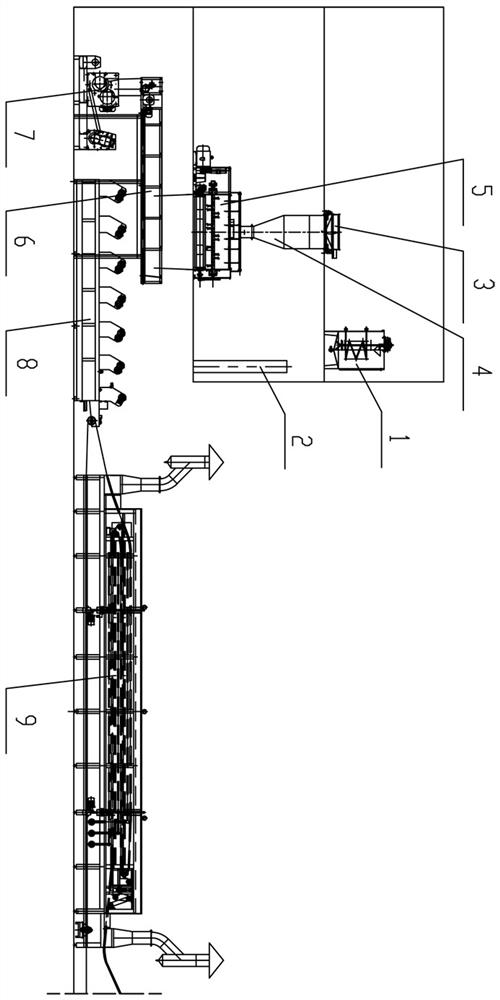

[0045]The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

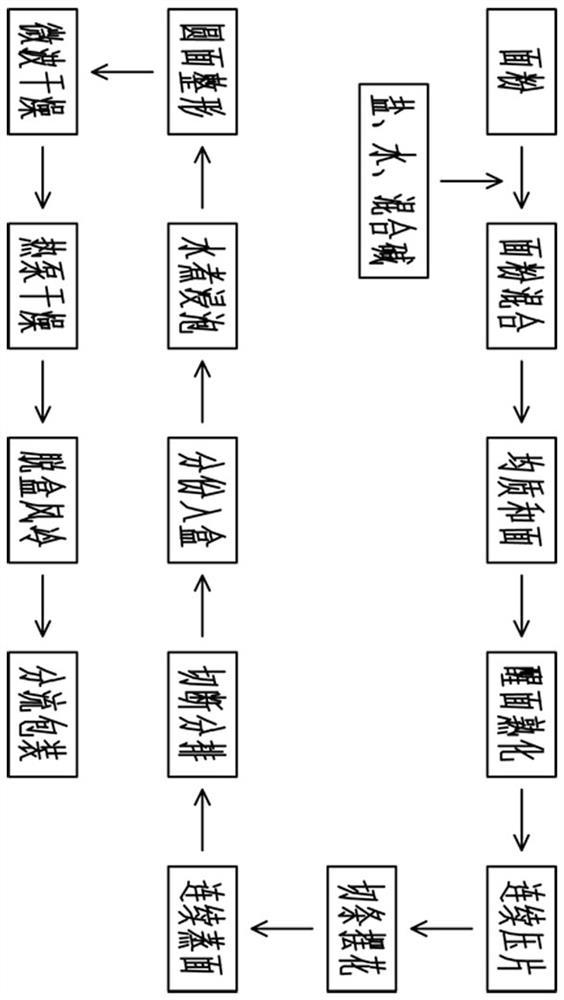

[0046] like Figure 1~Figure 8 Shown, a kind of green excellent product instant noodle production method comprises the following steps:

[0047] Step 1: Flour mixing: According to the requirements of proportioning flour 100kg, water 28~32kg, salt 0.5~2kg, and mixed alkali 0.14~0.2kg, use the brine mixer 1 to mix the brine auxiliary materials evenly. The brine auxiliary materials include water, table salt and mixed Alkali, then through the metering of brine metering device 2;

[0048] The flour enters the powder storage hopper 4 through the vibrating sieve 3, and the flour in the powder storage hopper 4 and the measured salt water auxiliary materials are input into the double-shaft continuous homogenizer 5 and mixed together at high speed. The announcement number is CN204134498U. A double-shaft continuous homogenizer for materials, this part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com