Cleaning method of thin-film solar cell bus bar welding joint

A technology for solar cells and welding heads, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, welding equipment, etc., to achieve the effect of reducing the difficulty of operating techniques, simple steps, and easy-to-learn operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

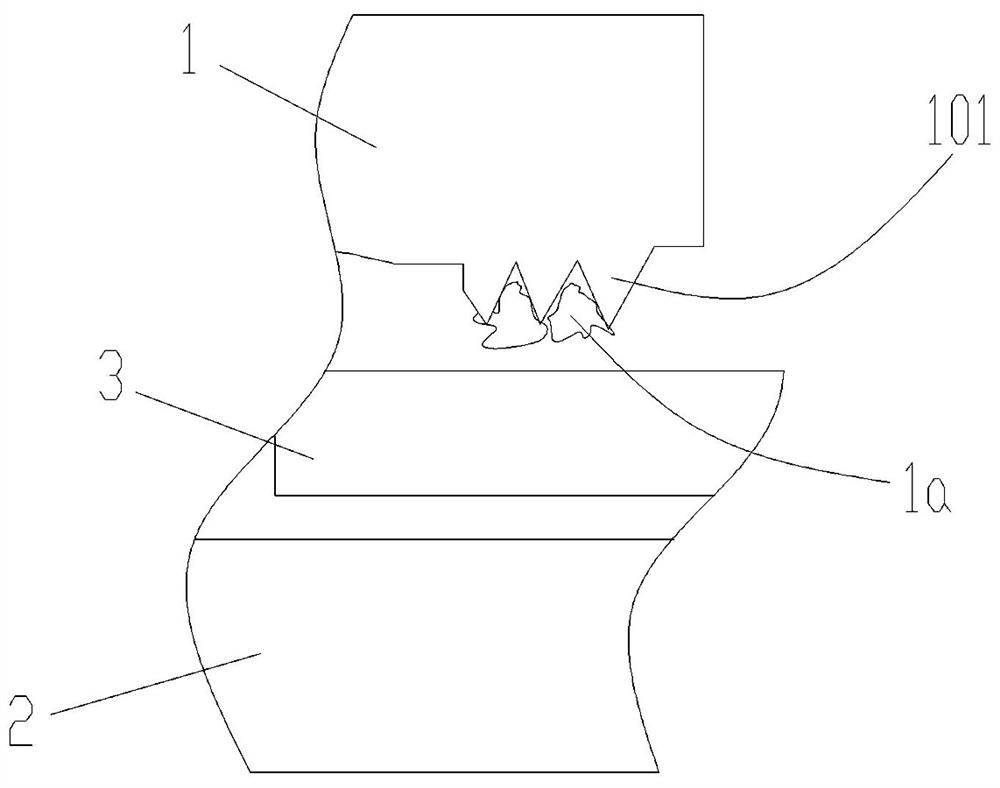

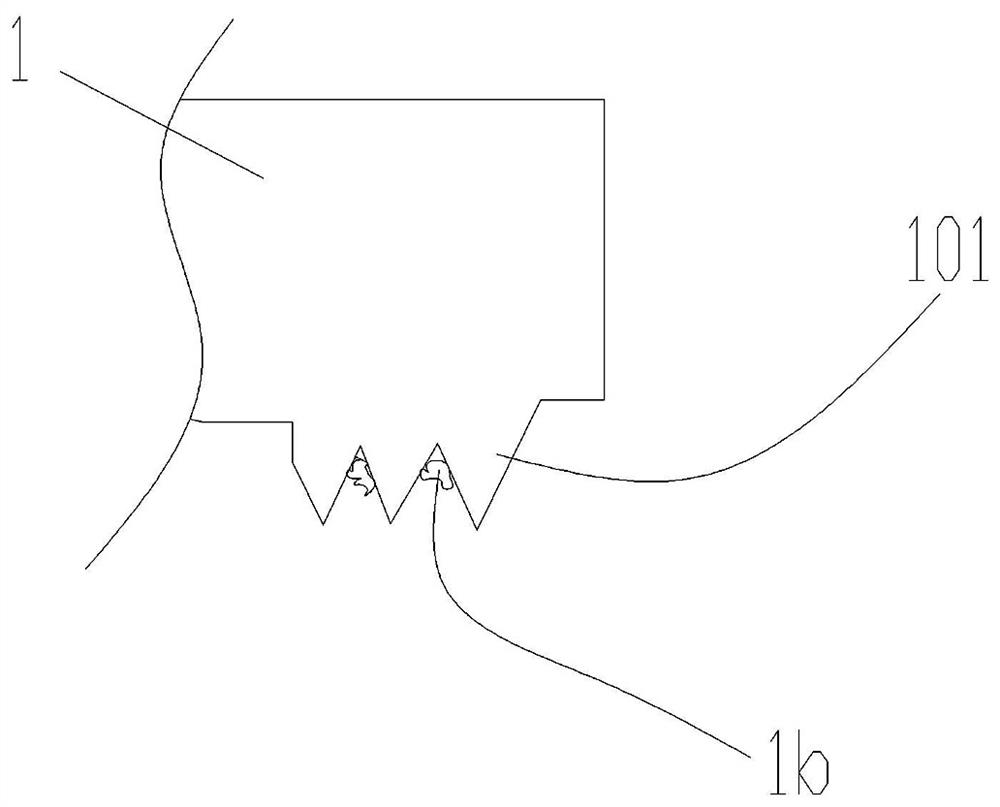

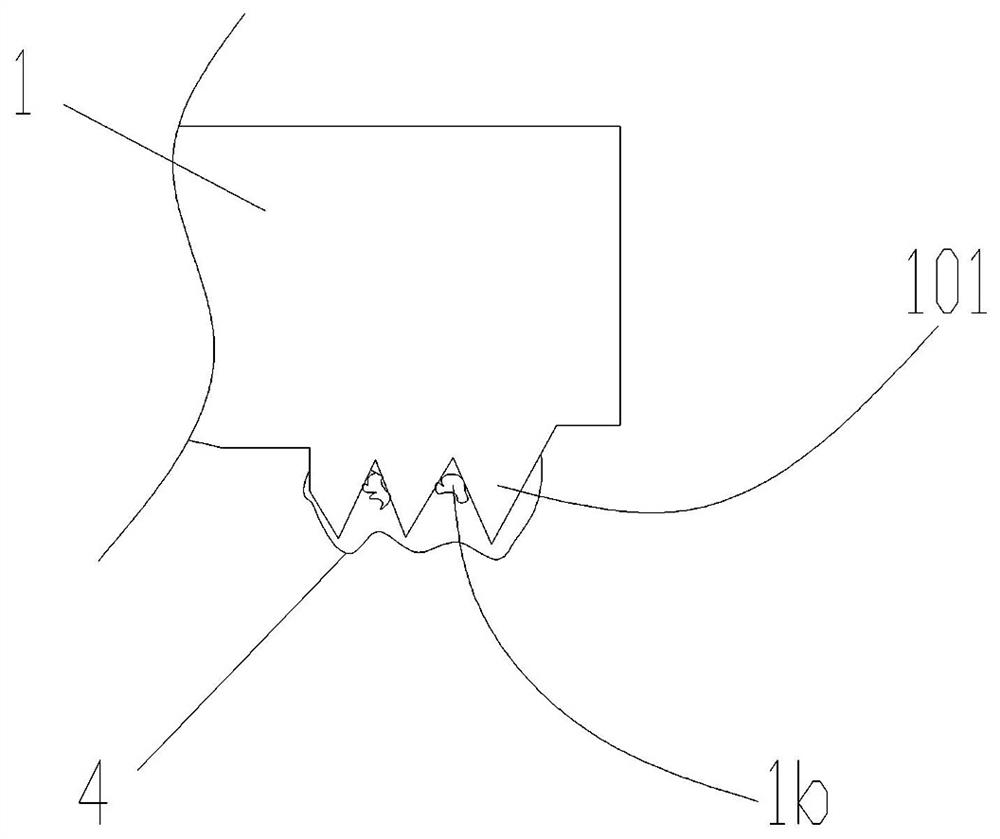

[0016] Such as Figure 1-3 Shown, a kind of cleaning method of thin-film solar cell bus bar welding head, it comprises the following steps: Step 1: on the soldering seat 2 below welding head 1, a size is set: thickness 3mm, width: 100mm, long 200mm bus bar A metal plate 3 made of pure aluminum with the same material properties and hardness;

[0017] Step 2: Select the cleaning process parameters. The cleaning process parameters are different from the normal production process parameters. Generally, the amplitude percentage of the welding head will be increased by 50%. The significance of the amplitude percentage parameter is to control the stroke of the tooth-shaped welding part 101 of the welding head. The large pieces of debris 1a are easily and quickly compatible with the metal plate 3 under high-frequency friction, so that the metal plate 3 can capture the large pieces of debris 1a on the toothed welding portion 101 of the welding head, thereby reaching the point of preli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com