An Aromatherapy Wood Cutting Ball Equipment

A ball cutting and aromatherapy technology, used in wood processing appliances, forming/shaping machines, special forming/shaping machines, etc., can solve the problem of slowing down cutting efficiency, splashing to the inside and outside of the equipment, and easy to accumulate in the inner hole of the cutting ball head. wall and other problems to achieve the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

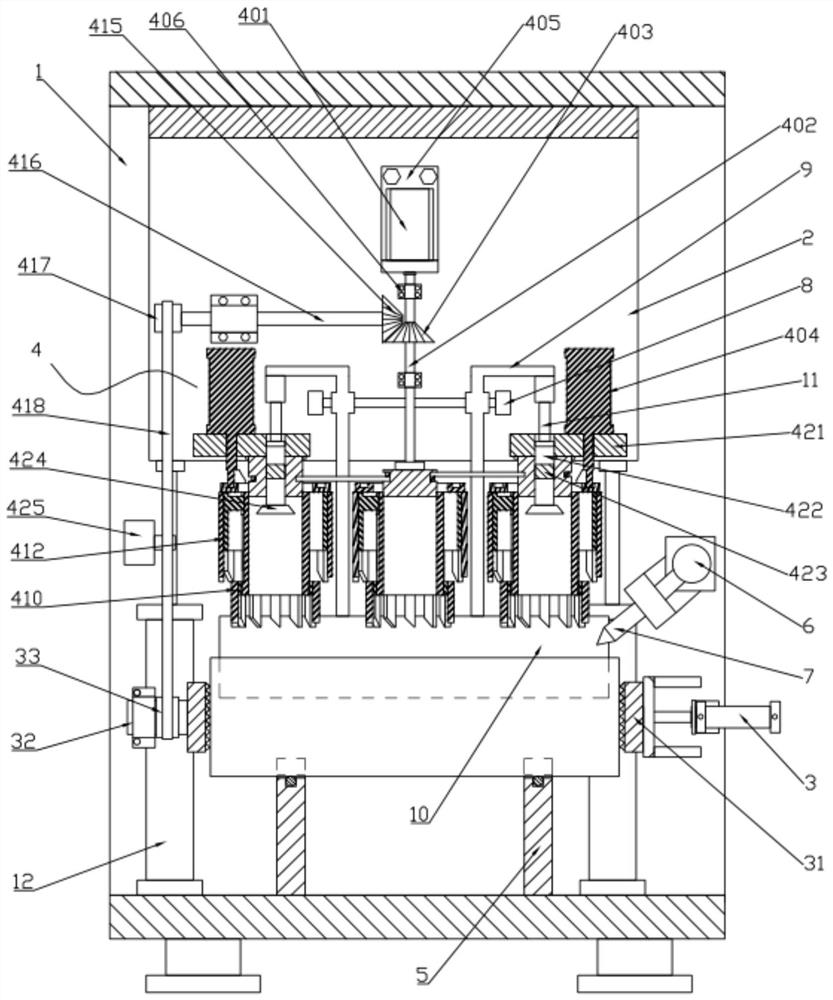

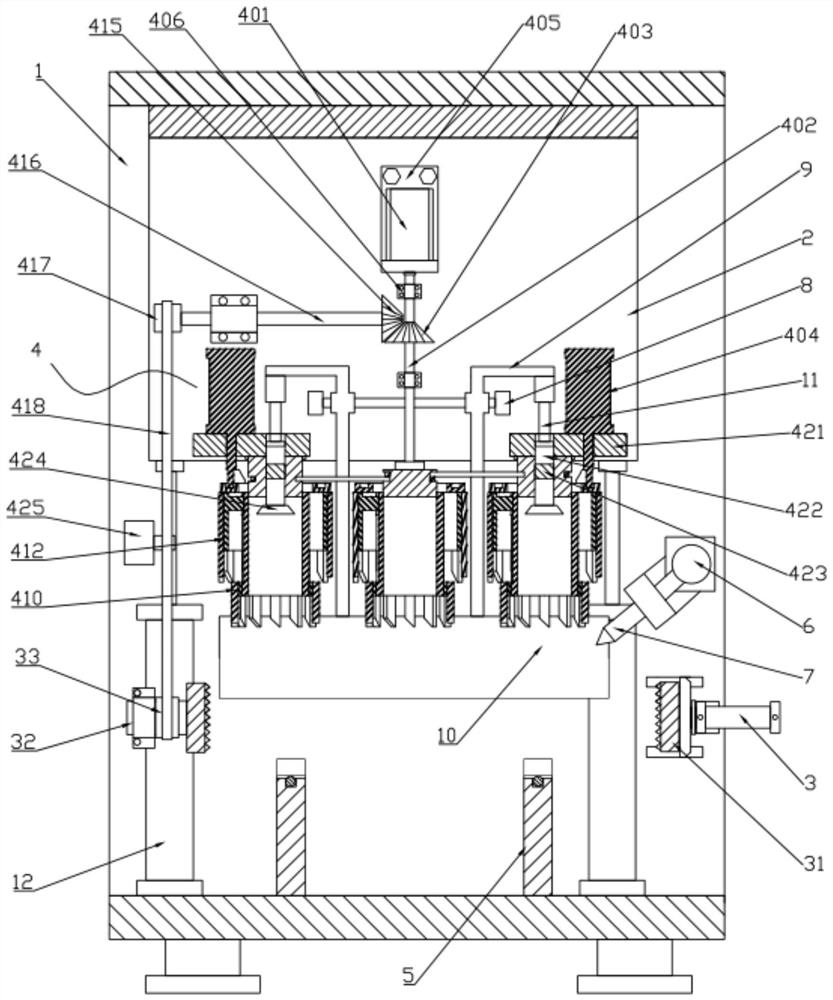

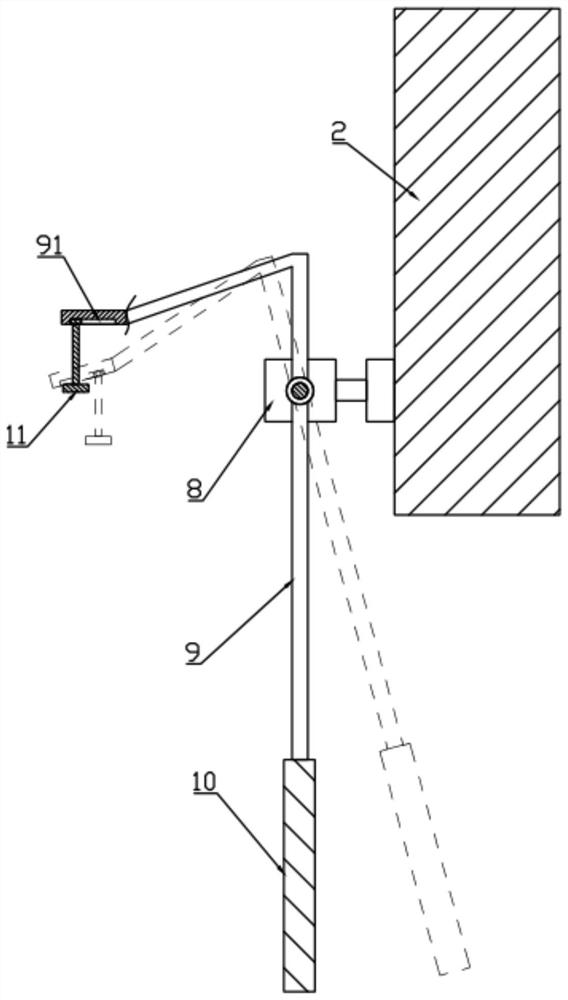

[0025] Such as Figure 1 to Figure 5 As shown, an aromatherapy wood cutting equipment includes a machine base 1, an inverted "L"-shaped mounting seat 2, a cylinder 3 and a cutting mechanism 4. The machine base 1 is "匚" shaped and the inner bottom wall is provided with a base Table 5, the mounting base 2 is set inside the machine base 1 through two symmetrically arranged hydraulic cylinders 12, the cutting mechanism 4 is installed on the mounting base 2, and is used for simultaneous multi-ball cutting and tooling of the wood to be processed. The inner wall of the machine base 1 is provided with a liquid outlet head 7 through the liquid supply pump 6, the cylinder 3 is installed on the inner wall of the machine base 1 and placed under the liquid sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com