Method for preparing pyrolytic carbon by using acetaldehyde precursor

A technology for pyrolysis of carbon and precursors, which is applied in the preparation/purification of carbon, etc., to achieve the effects of convenient operation, simple and reasonable preparation method, and wide process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

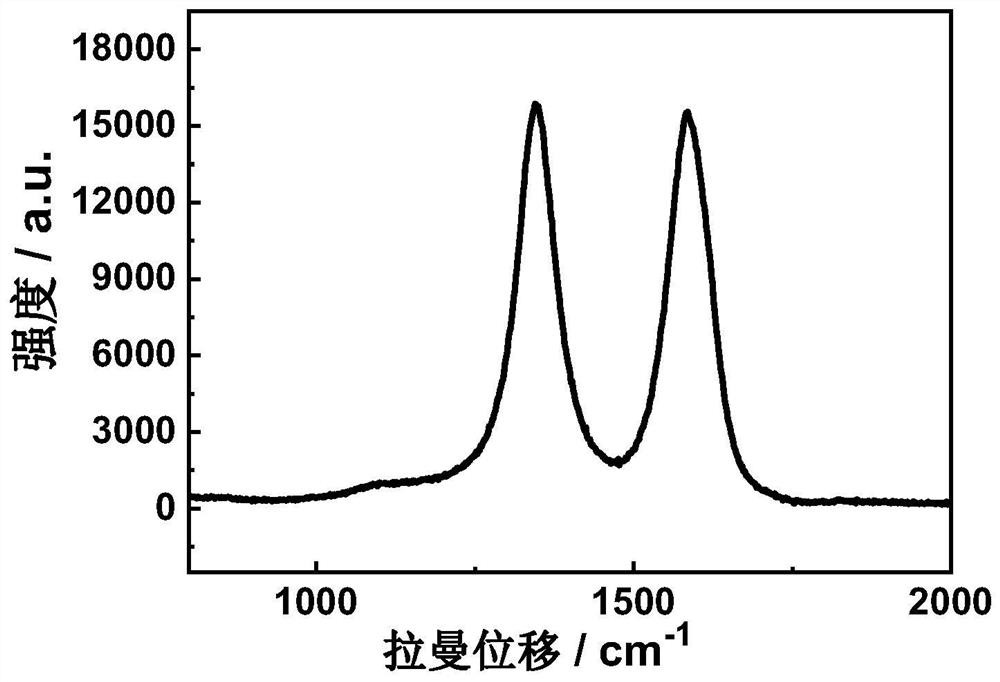

[0024] Step 1: A quartz glass sheet with a size of 10×10×2 mm is used as a substrate, and an acetaldehyde organic solution (purity is 40%) is used as a precursor. Nitrogen (N2, 99.99% by volume) was used as the carrier gas and diluent gas.

[0025] Step 2: Pour 4 bottles of acetaldehyde organic solution into a closed metal container, and make the acetaldehyde organic solution turn into steam to participate in the reaction by bubbling.

[0026] Step 3: Using the isothermal chemical vapor infiltration method, place the quartz glass substrate in step 1 in a deposition reactor, and let the gas pass through the quartz glass substrate in parallel from the bottom to the top. Then the temperature was raised from room temperature to 1050°C at a rate of 8°C / min. Control the acetaldehyde gas flow in the flowmeter at 80 sccm, deposit at 1050°C for 5 hours, then gradually lower the temperature from 1050°C to 200°C, turn off the power, and take out the sample after natural cooling. The wh...

Embodiment 2

[0028] Step 1: Use a density of 0.47g / cm 3 The 2D carbon felt (50 × 25 × 10 mm in size) was used as the substrate, and the organic solution of acetaldehyde (40% purity) was used as the precursor. Nitrogen (N2, 99.99% by volume) was used as the carrier gas and diluent gas.

[0029] Step 2: Pour 5 bottles of acetaldehyde organic solution into a closed metal container, and make the acetaldehyde organic solution turn into steam to participate in the reaction by bubbling.

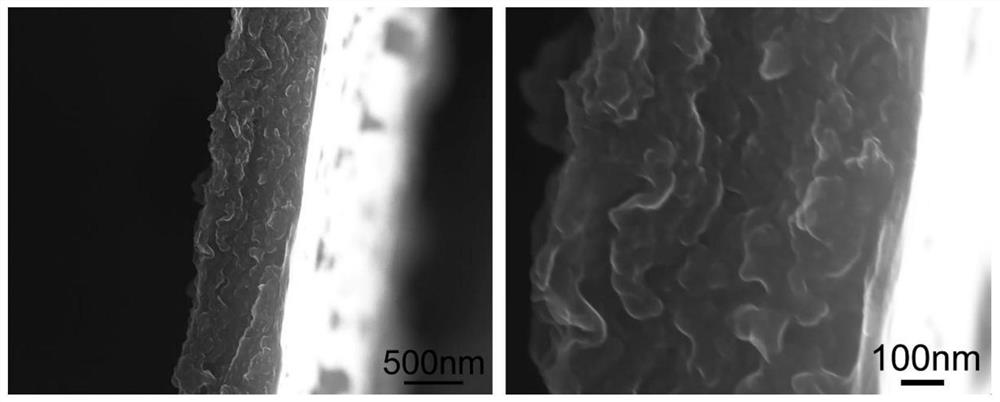

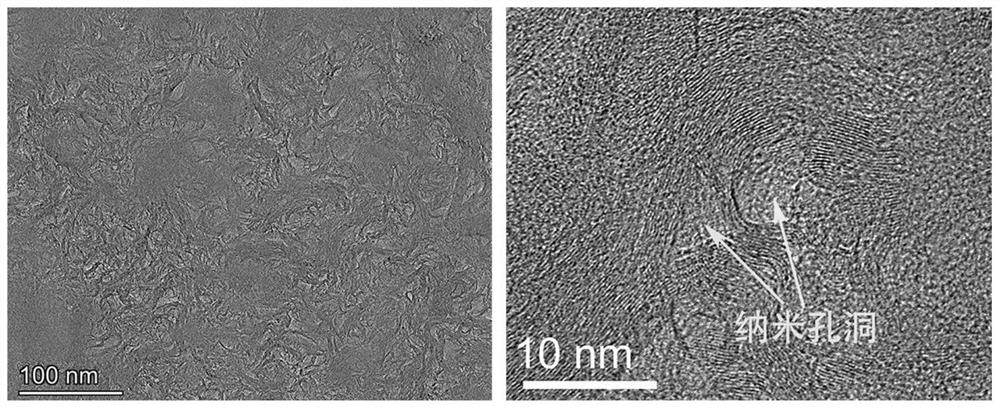

[0030] Step 3: Using the isothermal chemical vapor infiltration method, place the carbon felt substrate in step 1 in the deposition reactor, and let the gas pass through the carbon felt substrate in parallel from bottom to top. Then the temperature was raised from room temperature to 1090° C. at a rate of 10° C. / min. Control the acetaldehyde gas flow in the flowmeter to 100 sccm, deposit at 1090°C for 15 hours, then gradually lower the temperature from 1090°C to 200°C, turn off the power, and take out the samp...

Embodiment 3

[0032] Step 1: Use a density of 0.6g / cm 3 The 2D carbon felt (50 × 25 × 10 mm in size) was used as the substrate, and the organic solution of acetaldehyde (40% purity) was used as the precursor. Nitrogen (N2, 99.99% by volume) was used as the carrier gas and diluent gas.

[0033] Step 2: Pour 5 bottles of acetaldehyde organic solution into a closed metal container, and make the acetaldehyde organic solution turn into steam to participate in the reaction by bubbling.

[0034] Step 3: Using the isothermal chemical vapor infiltration method, place the carbon felt substrate in step 1 in the deposition reactor, and let the gas pass through the carbon felt substrate in parallel from bottom to top. Then the temperature was raised from room temperature to 1120°C at a rate of 12°C / min. Control the acetaldehyde gas flow in the flowmeter at 110 sccm, deposit at 1120°C for 20 hours, then gradually lower the temperature from 1120°C to 200°C, turn off the power, and take out the sample af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com