Smelting method of ZG06Cr13Ni4Mo steel and ZG06Cr13Ni4Mo steel

A smelting method and rough smelting technology, applied in the smelting of ZG06Cr13Ni4Mo steel and ZG06Cr13Ni4Mo steel field, can solve the problems of long smelting production cycle, high oxygen content in molten steel, and high operation requirements, and achieve reduced equipment complexity, low smelting cost, and technological process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

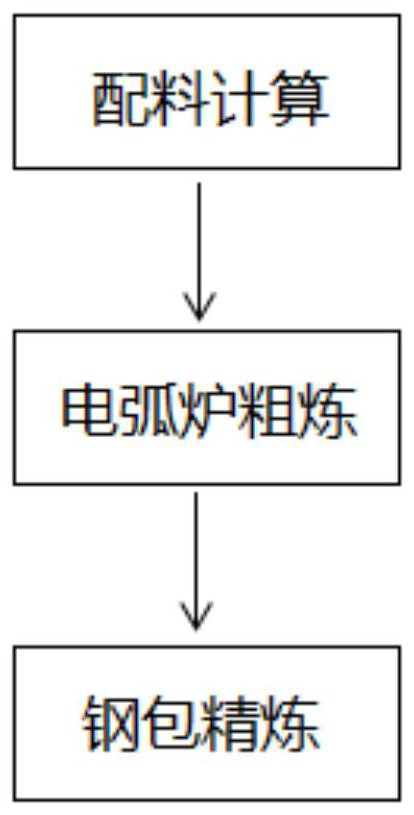

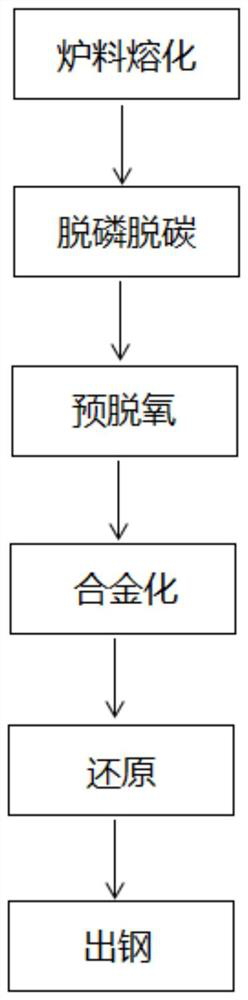

Method used

Image

Examples

Embodiment Construction

[0022] The invention can be more readily understood by reference to the following detailed description of the preferred practice of the invention and the included examples. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. In case of conflict, the definitions in this specification shall prevail. As used herein, the term "prepared from" is synonymous with "comprising". As used herein, the terms "comprises," "including," "has," "containing," or any other variation thereof, are intended to cover a non-exclusive inclusion. For example, a composition, step, method, article, or device comprising listed elements is not necessarily limited to those elements, but may include other elements not explicitly listed or inherent to such composition, step, method, article, or device. element.

[0023] The conjunction "consisting of" excludes any unspecifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com