Epoxy floor trowelling device

An epoxy floor, leveling technology, applied in construction, building structure and other directions, can solve the problems of poor spreading effect, material mixed with impurities, affecting coating efficiency, etc., to reduce manual work, ensure smoothness, Improve smoothing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

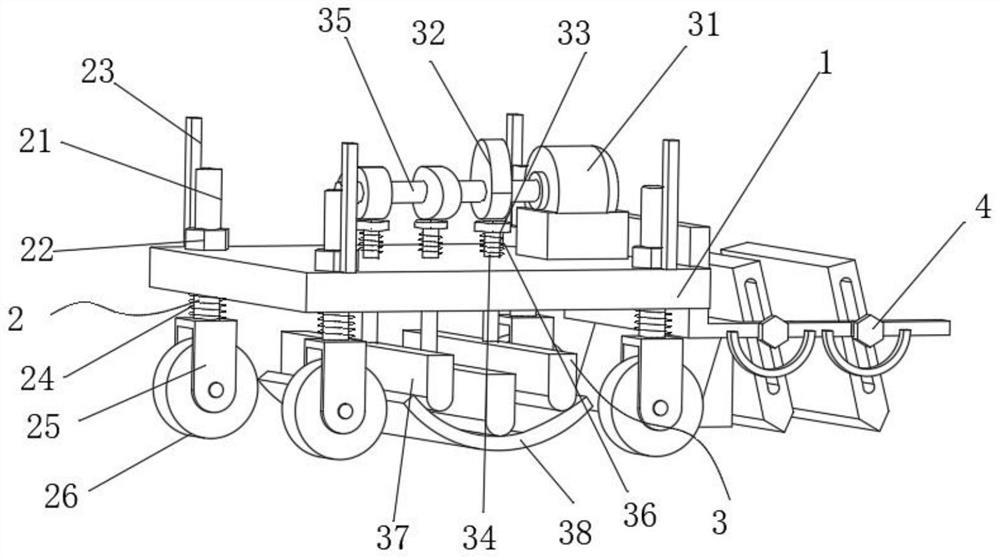

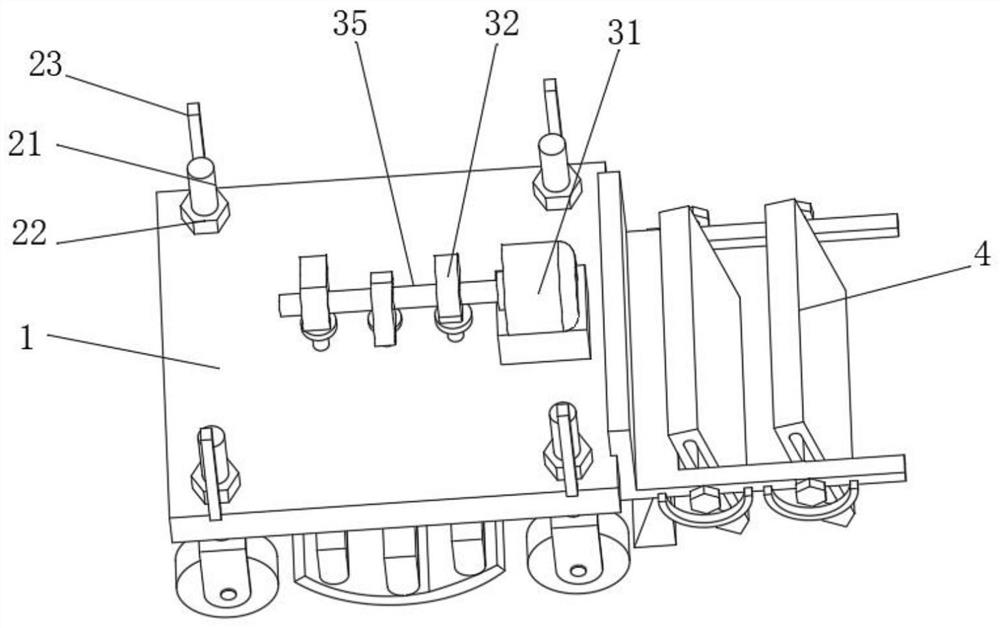

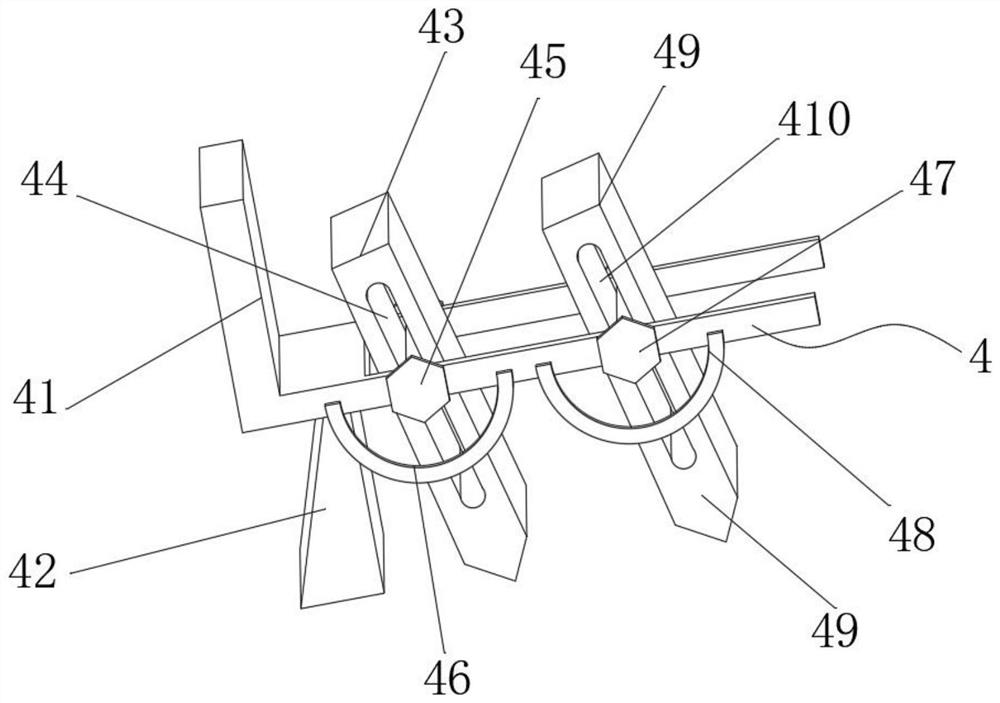

[0028] As an embodiment of the present invention, the vibration spreading structure 3 includes a vibration motor 31, a rotating cam 32, a limit plate 33, a return spring 34, a cam shaft 35, a vibrating rod 36, a spreading plate 37 and a rubber pad 38 , the inside of the horizontal plate of the bracket 1 is provided with a rod hole, the vibration rod 36 is vertically penetrated in the rod hole, the limit plate 33 is installed on the top of the vibration rod 36, and the return spring 34 is set on the vibration rod. The top of the rod 36, the vibrating motor 31 is mounted on the support 1 through bolts, the rotating shaft of the vibrating motor 31 is fitted with a camshaft 35, and the camshaft 35 is set with a rotating cam 32, and the vibrating rod The bottom end of 36 is welded with flat spreading plate 37, and the bottom side of described flat spreading plate 37 is pasted with rubber pad 38.

[0029] As an embodiment of the present invention, a plurality of rotating cams 32 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com