Graphite negative electrode material, preparation and application thereof

A graphite anode and graphite technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of small interlayer spacing, large EIS, low high-rate discharge retention rate, etc., and achieve easy mass production and reduce adverse effects. , the effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

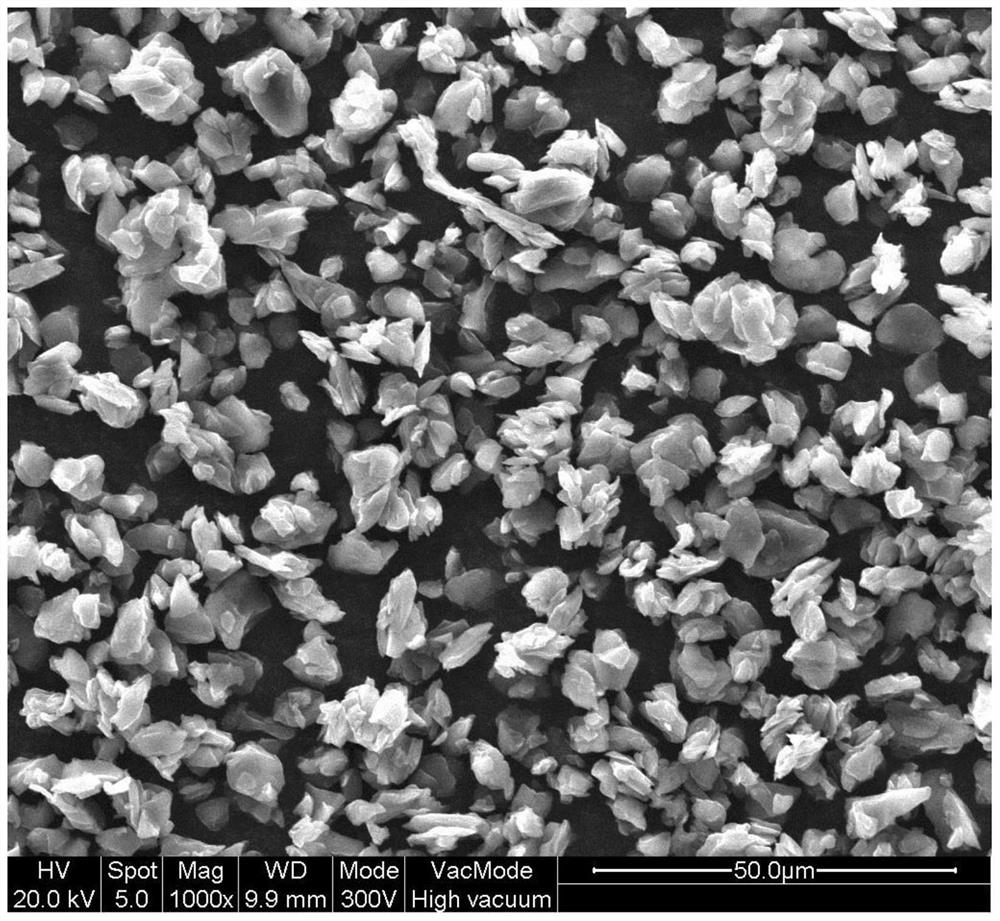

Image

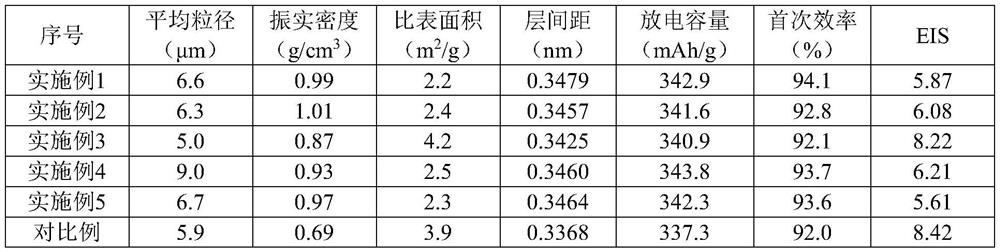

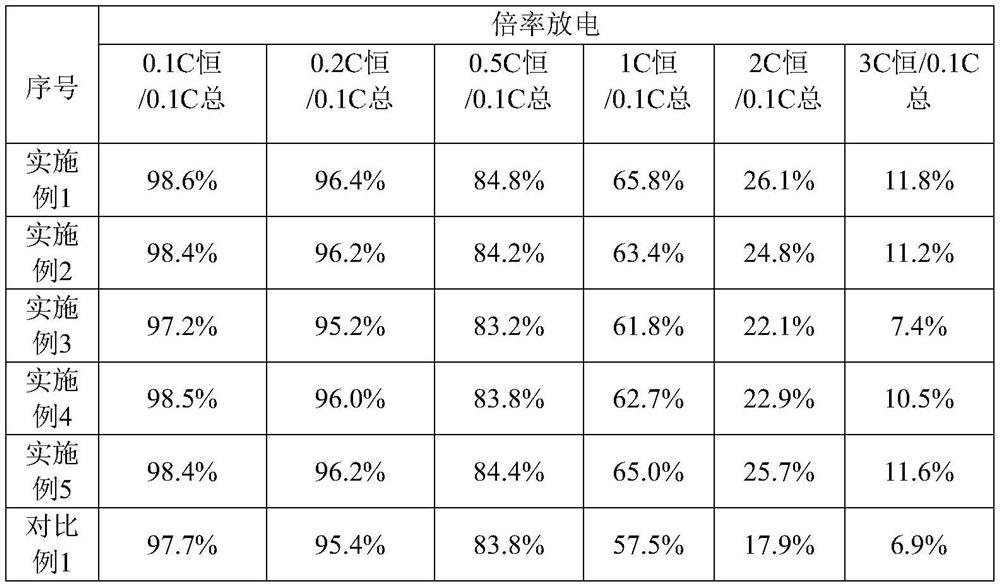

Examples

Embodiment 1

[0056] The preparation method of the graphite negative electrode material of the present embodiment, concrete steps are:

[0057] Step 1. Mechanically pulverizing oil-based needle coke as a raw material to obtain 100 kg of particles with an average particle size of 5.8 μm and a particle size range of 0.9-24.5 μm;

[0058] Step 2. Put the obtained granules into a horizontal reactor, and granulate under an inert atmosphere. The temperature of granulation is 700°C, and the time is 8 hours, so as to remove part of the volatile matter. The reaction process makes the surface of the granules and micropores A thin layer of gas-phase carbon is coated in the middle;

[0059] Step 3: Perform high-temperature graphitization treatment on the obtained material. The graphitization temperature is 3000°C and the time is 30 hours. ≥330mAh / g;

[0060] Step 4, classifying the obtained artificial graphite particles, screening out artificial graphite fine particles with an average particle size o...

Embodiment 2

[0065] This embodiment is similar to embodiment 1, the difference is that: the preparation process does not go through step 4 classification treatment. The obtained artificial graphite negative electrode material for lithium-ion batteries is a single particle with an average particle size of 6.3 μm and a particle size distribution range of 0.7-26.0 μm, including graphite and a hard carbon layer uniformly coated outside the graphite, the carbon The thickness of the layer is 5-50 nm.

Embodiment 3

[0067] This example is similar to Example 1, except that: in step one, the average particle size is 4.5 μm obtained by mechanical pulverization, and the particle size range is 0.3-17.5 μm; in step three, artificial graphite particles are obtained after graphitization , the average particle size is 4.6 μm, the particle size distribution range is 0.3-17.0 μm, and the discharge capacity is ≥330mAh / g; the preparation process has not undergone step four classification treatment. The obtained artificial graphite negative electrode material for lithium-ion batteries is a single particle with an average particle diameter of 5.0 μm and a particle size distribution range of 0.5-18.5 μm, including graphite and a hard carbon layer uniformly coated outside the graphite, the carbon The thickness of the layer is 2-25 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com