Multilayer seed germination and plant development media

A plant development and seed technology, applied in planting substrates, botanical equipment and methods, gardening tools/equipment, etc., can solve problems such as cost increase, reduce evaporation, reduce plant decay and contact with algae, and achieve good harvesting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

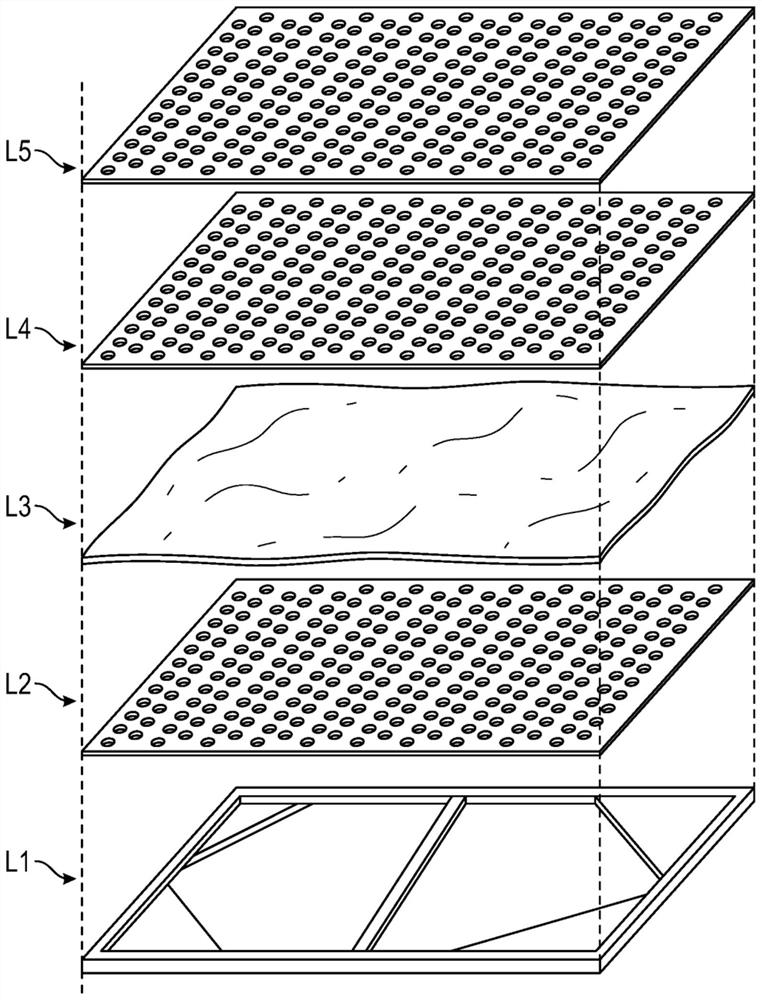

[0112] This example illustrates the growth of baby spinach on a non-woven substrate using multi-layer flat panels.

[0113] Spinach seeds were germinated and developed into plants on plates using a four-layer structure. The structure used is illustrated in Figures 9 and 10 and includes a frame (905 (with figure 1 L1 in the same)), a polyvinyl chloride (PVC) support layer 1090 with a plurality of openings 1092 in a grid or array; a paper-based soilless growth medium (930, 1030), and a , 1030) on top of a PVC light shielding layer (1020) having a plurality of openings (950) in a grid or array. In this example, the paper-based soilless growing medium supports seed germination and root penetration. Holds the paper in place between the support layer and the shade without stretching or pinning the paper to the bottom support or shade. The openings in the obscuring layer were about 0.32 centimeters (0.125 inches) in diameter and were spaced about 0.95 centimeters (0.375 inches) ap...

Embodiment 2

[0119] This example demonstrates a yield of over 90% of the developed plants grown on the multi-layer plates and low growth of algae on the soilless growth medium.

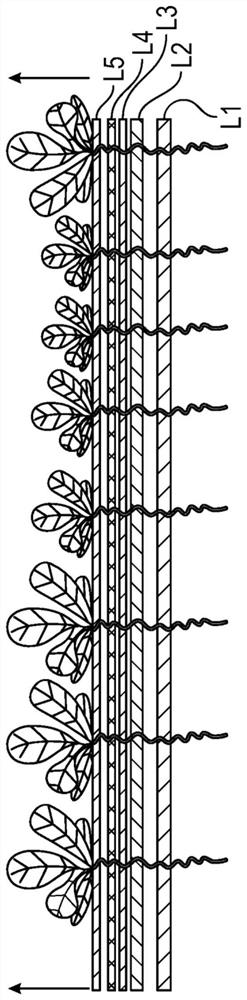

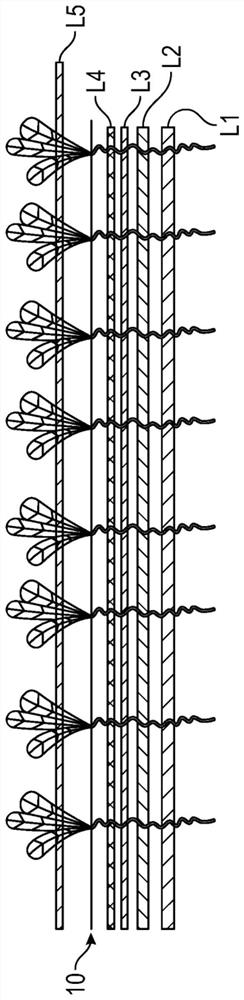

[0120] Arugula was grown on two flat panels consisting of a metal frame (L1), a bottom support layer (L2), an unstretched polyester-based soilless fabric growing medium surrounded by an adjacent shade layer and The upper layer is fixed in place. Unstretched polyester-based fabric soilless growing media supports seed germination and root penetration through the media. The light-shielding layer and the upper layer are made of opaque, non-transparent white plastic material. The light transmittance (determined by visual inspection) of the unopened or solid portions of the light shielding layer and upper layer is less than the light transmittance through any openings in the light shielding layer. The upper layer, shade, fabric and support layer are sandwiched by two bolt fasteners attached to the frame ends. The ope...

Embodiment 3

[0127] This example demonstrates that under the same test conditions, the evaporation rate of water from a test plate with a shading layer on top of a soilless growth medium is reduced compared to the evaporation rate of water from a plate without a shading layer.

[0128]Measurements were made on a control panel (comprising a polar fleece fabric as disclosed in Harwood, U.S. Patent Publication No. 20140137471) and a test panel (comprising the same polar fleece fabric and an opaque layer (both open and solid) on top of the fabric. ) of the evaporation rate of water. The test equipment consisted of a 0 to 400 lb scale with a data port located under the plate to measure the change in weight over time.

[0129] Measure the air temperature, humidity, and water temperature in the test rig using sensors and a data logger to record the sensor output. The control and test panels were similar in size, measuring approximately (1.5 meters x 0.75 meters; 5 feet x 2.5 feet). Place the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com