Preparation method of straddle type monorail vehicle framework bottom plate pre-assembly

A monorail vehicle and straddle-type technology, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of high processing cost and low weld bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

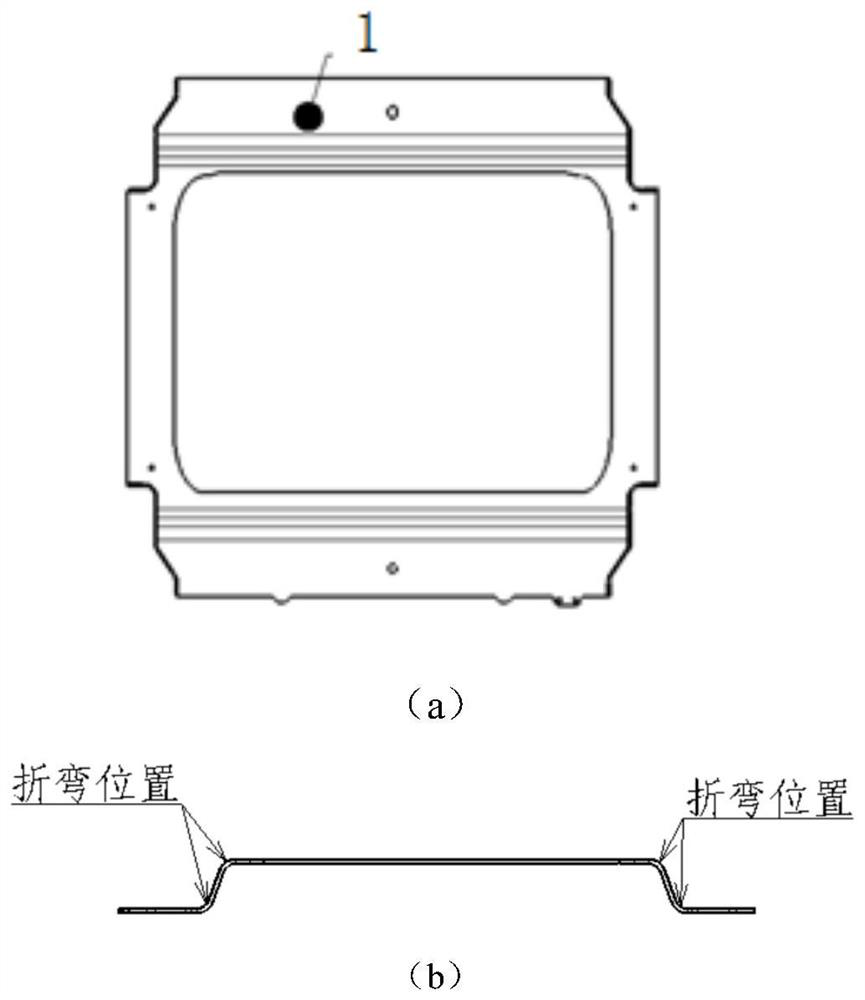

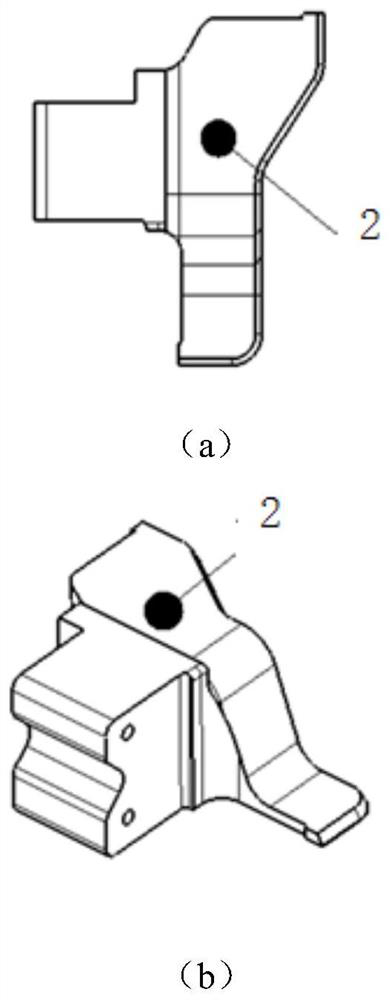

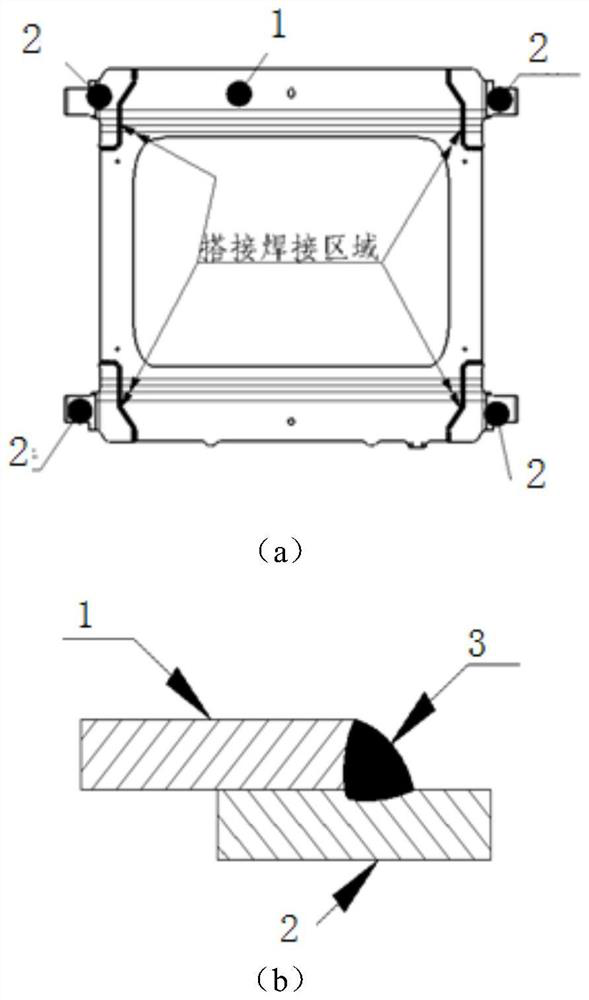

[0035] The preparation method of the straddle-type monorail frame base plate pre-assembly of this embodiment is described from the aspects of welding and material processing, and the specific contents are as follows:

[0036] ①Change the type of welded joints, change the welded joints from lap joints to butt joints (such as Figure 4 shown). Butt weld 4 is the welding of two workpieces in a horizontally opposite position (such as Figure 4 b) By processing the groove on the workpiece, the depth of the weld can be the same as the thickness of the base metal, and the two workpieces can be seamlessly connected.

[0037] Welding must be completed continuously when welding each weld seam, and arc stop is not allowed during welding. The welding operation is completed by welding the flat welding welding area 4a first, then turning to the vertical welding we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com