Water-based glass colored jade sand material and preparation method thereof

A glass and color technology, applied in the field of water-based glass colored jade sand material and its preparation, glass colored jade sand material and its preparation, to achieve the effect of durable coating, good adhesion, and energy saving of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The water-based glass colored jade sand material of this embodiment includes component A and component B, and the mass ratio of component A to component B is 1:6.

[0075] Among them, in terms of mass percentage, component A is composed of 80% of XP2487 hydrophilic aliphatic isocyanate, 15% of N3900 low-viscosity aliphatic isocyanate, and 5% of GF40 isocyanate silane coupling agent.

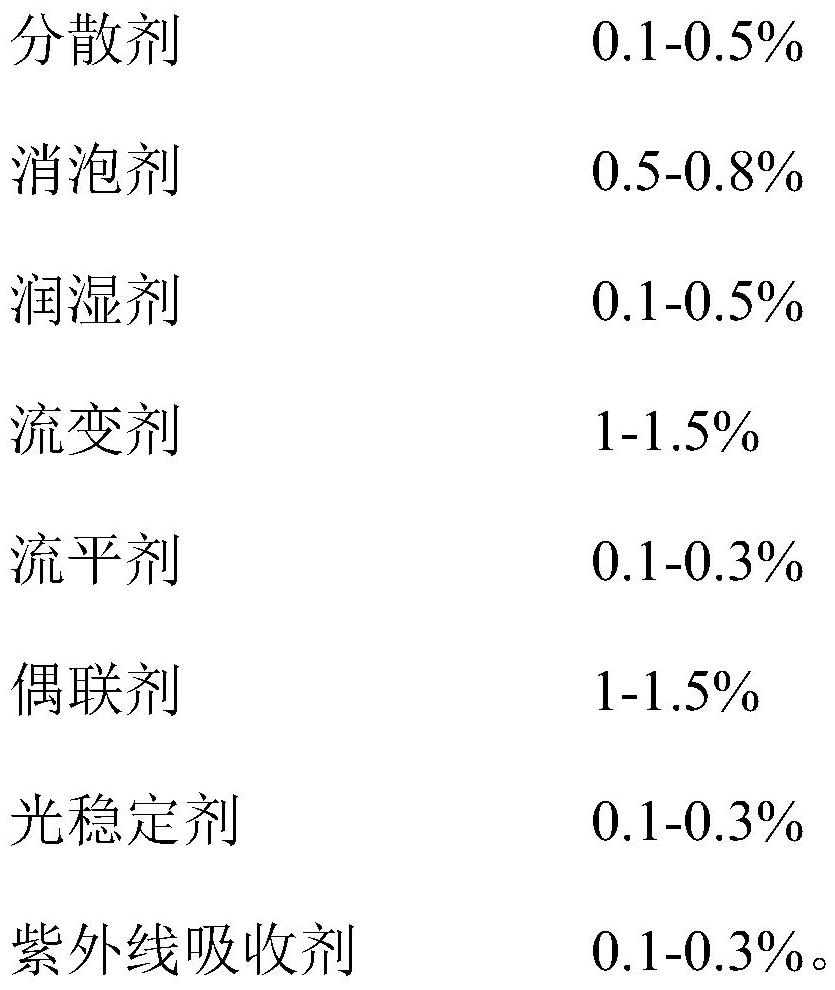

[0076] Among them, in terms of mass percentage, component B consists of 20% of A2695 hydroxyl acrylic dispersion, 10% of U2766 hydroxyl polyurethane dispersion, 10% of EPICLON H502 epoxy resin dispersion, 32.1% of deionized water, 18% of silicon micropowder, silicon dioxide Microsphere 4%, bentonite 0.5%, FX365 polyether copolymer dispersant 0.1%, TEGO845 polysiloxane defoamer 0.6%, W469 silicone wetting agent 0.5%, HX6008 polyurethane rheological agent 1.2%, BYK381 acrylic copolymer It consists of 0.1% logistics agent, 1.5% Z6040 epoxy silane coupling agent, 0.1% TINUVINS292 light stabili...

Embodiment 2

[0088] The water-based glass colored jade sand material of this embodiment includes component A and component B, and the mass ratio of component A to component B is 1:6.

[0089] Among them, in terms of mass percentage, component A is composed of 75% of XP2487 hydrophilic aliphatic isocyanate, 17% of N3900 low-viscosity aliphatic isocyanate, and 8% of GF40 isocyanate silane coupling agent.

[0090] Among them, in terms of mass percentage, component B consists of 27% of A2695 hydroxyl acrylic dispersion, 11% of U2766 hydroxyl polyurethane dispersion, 8% of EPICLON H502 epoxy resin dispersion, 24% of deionized water, 16% of silicon micropowder, silicon dioxide Microspheres 8%, bentonite 0.2%, FX365 polyether copolymer dispersant 0.5%, TEGO845 polysiloxane defoamer 0.8%, W469 silicone wetting agent 0.3%, HX6008 polyurethane rheology agent 1.5%, BYK381 acrylic copolymer It consists of 0.3% logistics agent, 1.3% Z6040 epoxy silane coupling agent, 0.3% TINUVINS292 light stabilizer, ...

Embodiment 3

[0102] The water-based glass colored jade sand material of this embodiment includes component A and component B, and the mass ratio of component A to component B is 1:6.

[0103] Among them, in terms of mass percentage, component A is composed of 85% of XP2487 hydrophilic aliphatic isocyanate, 10% of N3900 low-viscosity aliphatic isocyanate, and 5% of GF40 isocyanate silane coupling agent.

[0104]Among them, in terms of mass percentage, component B consists of 40% of A2695 hydroxyl acrylic dispersion, 10% of U2766 hydroxyl polyurethane dispersion, 5% of EPICLON H502 epoxy resin dispersion, 28.6% of deionized water, 10% of silicon micropowder, silicon dioxide Microsphere 2%, bentonite 0.3%, FX365 polyether copolymer dispersant 0.3%, TEGO845 polysiloxane defoamer 0.6%, W469 silicone wetting agent 0.1%, HX6008 polyurethane rheological agent 1%, BYK381 acrylic copolymer It consists of 0.2% logistics agent, 1% Z6040 epoxy silane coupling agent, 0.2% TINUVINS292 light stabilizer, 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com