Method for preparing trace element water-soluble fertilizer by utilizing manganese-containing slag and zinc-containing rotary kiln slag

A trace element, rotary kiln technology, applied in liquid fertilizers, fertilizer mixtures, applications, etc., can solve problems such as insufficient utilization of manganese-containing slag and zinc-containing rotary kiln slag, and achieve low sulfur and impurity metal elements. The effect of high iron content and full resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

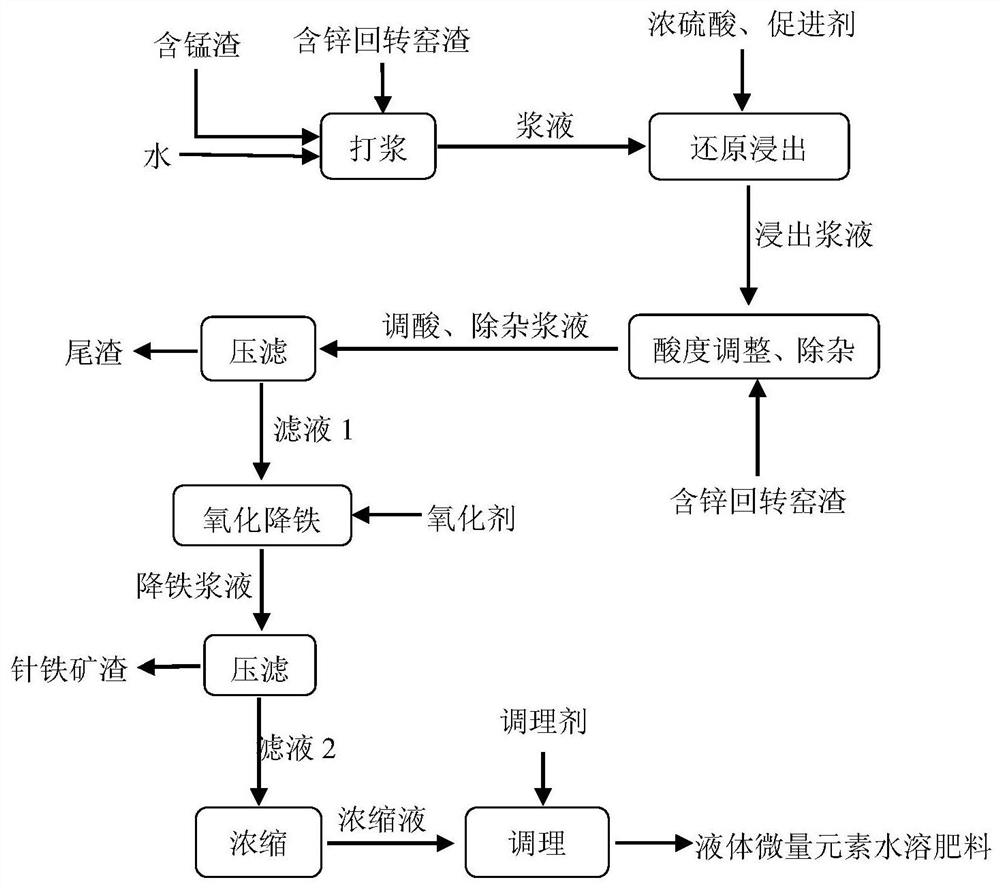

Method used

Image

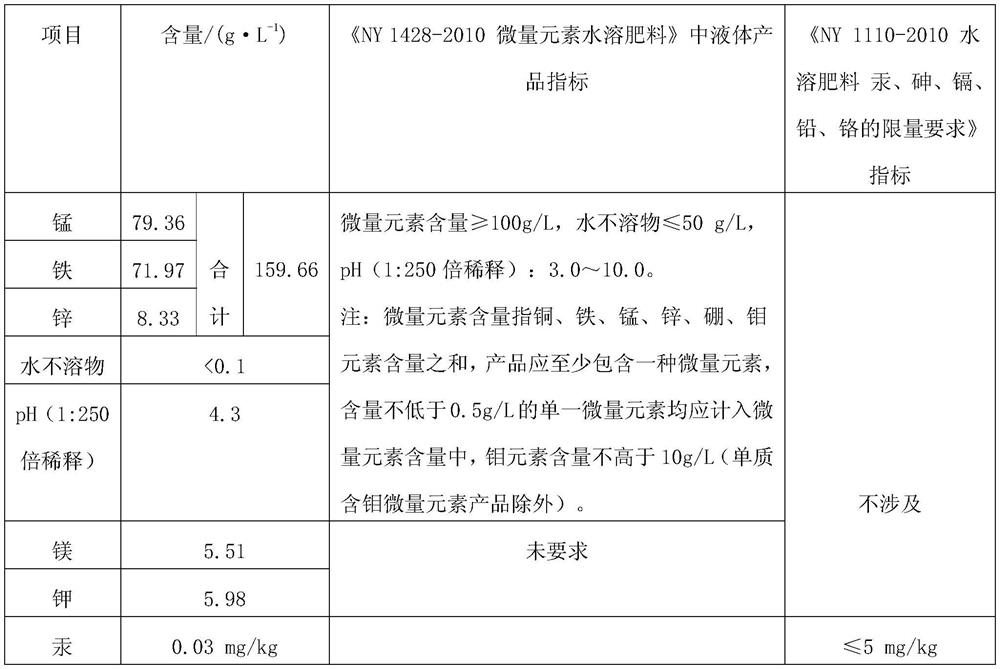

Examples

Embodiment 1

[0054] The method for preparing trace element water-soluble fertilizer by utilizing manganese-containing slag and zinc-containing rotary kiln slag comprises the following steps:

[0055] The detection of the main components of the manganese-containing slag involved in the present embodiment is as follows:

[0056] Element mn Fe Si C Al Ca Mg K content(%) 9.27 13.54 12.72 6.18 2.86 0.59 0.24 0.75 Element Na Ni co Cr Pb Cd Zn Cu content(%) 0.87 0.073 0.035 0.038 0.006 0.008 0.12 0.032

[0057] The detection of the main components of the zinc-containing rotary kiln slag involved in this embodiment is as follows:

[0058] Element Fe C SiO 2

Fe 3 o 4

FeO FeS CaO content(%) 43.34 8.10 14.33 4.67 14.11 1.46 4.21 Element MgO MnO ZnO K 2 o

Al 2 o 3

CaS co content(%) 2.37 1.39 3.48 0.12 4.76 0.87 0.06 Element Cd Cu Cr Pb ...

Embodiment 2

[0074]The method for preparing trace element water-soluble fertilizer by utilizing manganese-containing slag and zinc-containing rotary kiln slag comprises the following steps:

[0075] The chemical composition data of the manganese-containing slag and the zinc-containing rotary kiln slag of the present embodiment are the same as in Example 1;

[0076] 1) Beating: mix the manganese-containing slag and zinc-containing rotary kiln slag that have passed through a 100-mesh sieve at a mass ratio of 6:1 to obtain a mixture, and put the mixture and water into the stirring tank at a solid-to-liquid mass ratio of 1:2 beating to obtain slurry;

[0077] 2) add promotor in the slurry that upward step obtains, after stirring evenly, add dropwise the concentrated sulfuric acid that mass content is 98% and carry out reduction leaching reaction, the addition of promotor is 5% of slurry quality, controls the adding speed of vitriol oil so that The reaction pH value is between 0-1.5, the react...

Embodiment 3

[0090] The method for preparing trace element water-soluble fertilizer by utilizing manganese-containing slag and zinc-containing rotary kiln slag comprises the following steps:

[0091] The chemical composition data of the manganese-containing slag and the zinc-containing rotary kiln slag of the present embodiment are the same as in Example 1;

[0092] 1) Beating: mix the manganese-containing slag and zinc-containing rotary kiln slag that have passed through a 100-mesh sieve at a mass ratio of 4:1 to obtain a mixture, and put the mixture and water into the stirring tank at a solid-to-liquid mass ratio of 1:4 beating to obtain slurry;

[0093] 2) add promotor in the slurry that upward step obtains, after stirring evenly, add dropwise the concentrated sulfuric acid that mass content is 98% and carry out reduction leaching reaction, the addition of promotor is 4% of slurry quality, controls the adding speed of vitriol oil so that The reaction pH value is between 0-1.5, the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com