Composite material for stationery commodities and process for manufacturing stationery commodities and inkstone by using composite material

A technology of composite materials and supplies, which is applied in the field of composite materials and its production of stationery and inkstones. It can solve the problems of rough surface, difficulty in inkstones having a warm and delicate feel, and low service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

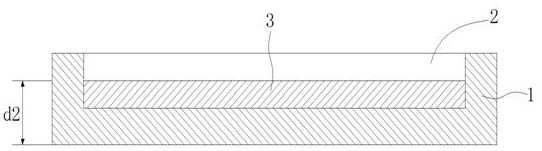

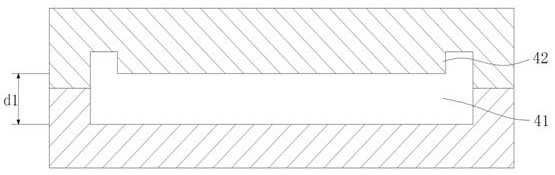

Image

Examples

Embodiment 1

[0040] S1: In the composite material, 12 parts of unsaturated polyester resin, 10 parts of glass fiber, 0.8 part of color paste, 4 parts of low shrinkage agent, 0.5 part of process additive, and 60 parts of filler, put each component in this weight part into the container, and stir until evenly mixed to obtain a mixed slurry;

[0041] S2: pour the mixed slurry into the mold cavity of the mold, and press molding, wherein the mold pressure is 56cm when pressing 2 / kg, the mold temperature is 55°C, and the pressing time is 0.8h;

[0042] S3: Take out the molding blank from the mold, and cool it naturally to get the inkstone made of composite material.

Embodiment 2

[0044] S1: In the composite material, 16 parts of unsaturated polyester resin; 12 parts of glass fiber; 1 part of color paste; 7 parts of low shrinkage agent; into the container, and stir until evenly mixed to obtain a mixed slurry;

[0045] S2: Pour the mixed slurry into the mold cavity of the mold, press molding, and the mold pressure is 70cm 2 / kg, the mold temperature is 45°C, and the pressing time is 1h;

[0046] S3: Take out the formed stationery from the mold, and let it cool down naturally to obtain an inkstone made of composite material.

Embodiment 3

[0048] S1: In the composite material, 15 parts of glass fiber; 2 parts of color paste; 10 parts of low shrinkage agent; 1.5 parts of process additive; Homogenously, to obtain a mixed slurry;

[0049] S2: Pour the mixed slurry into the cavity of the mold and press to form, wherein the mold pressure is 50cm during pressing 2 / kg, the mold temperature is 60°C, and the pressing time is 1h;

[0050] S3: Remove the blank from the mold and cool it naturally to obtain an inkstone made of composite materials.

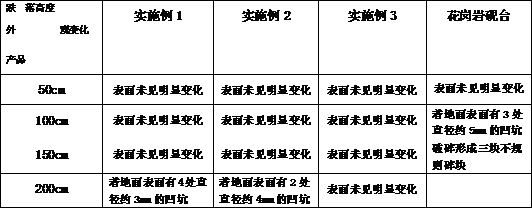

[0051] Among the above-mentioned embodiments 1 to 3, in addition to being used to make inkstones, it can also be used to make stationery such as paperweights. In addition, in the technique of the above-mentioned embodiment, after the calcium powder and quartz powder as fillers are all passed through 1000 sieves, they are put into the container and stirred, so that the fineness of calcium powder and lime can be increased, thereby improving the smoothness of the stationery surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com