Highlight extrusion halogen-free flame-retardant PC/ABS alloy material and preparation method thereof, and obtained product

A technology of alloy material and flame retardant, which is applied in the field of high-gloss extrusion halogen-free flame retardant PC/ABS alloy material and its preparation, which can solve the problem of no product and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

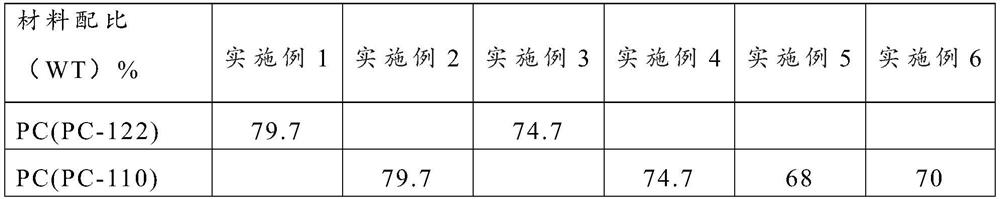

[0026] The applicant first optimized the components and proportions of the high-gloss extruded halogen-free flame-retardant PC / ABS alloy material. The optimization process and proportioning scheme of the components in the screening process are given in the following examples. These implementations The examples are intended to demonstrate the effect of the present invention and do not have a limiting effect.

[0027] Table 1 Example 1-11 Material Components and Proportions

[0028]

[0029]

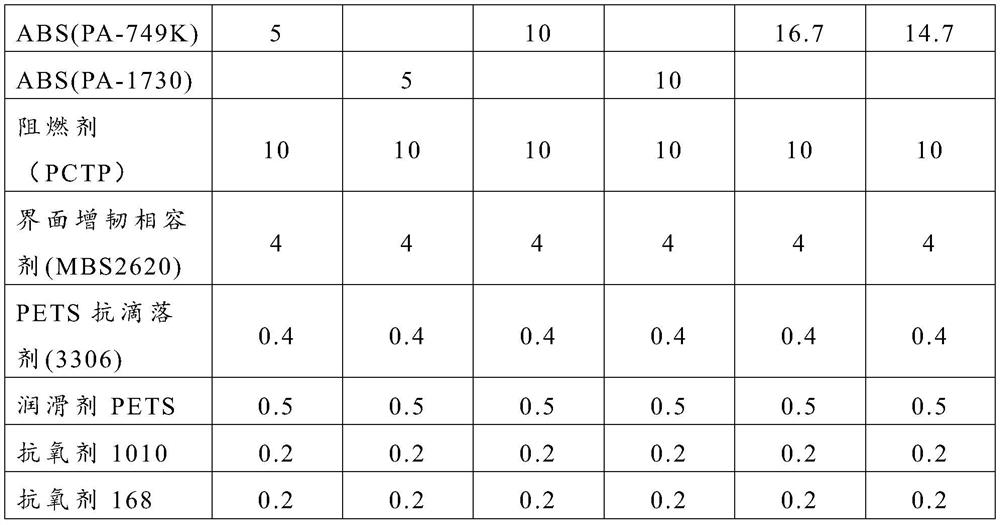

[0030] Table 1 (continued)

[0031]

[0032] According to the components and proportioning ratio in the above table 1, prepare the material according to the following method:

[0033] 1) Mix PC, ABS, and high-speed mixer for 3 minutes, then add flame retardant, interface toughening compatibilizer, PTFE anti-dripping agent, lubricant and antioxidant and mix for 5 minutes;

[0034] 2) Add the mixture obtained in step 2) to a co-rotating twin-screw extruder to extrude and granulate...

Embodiment 12-17

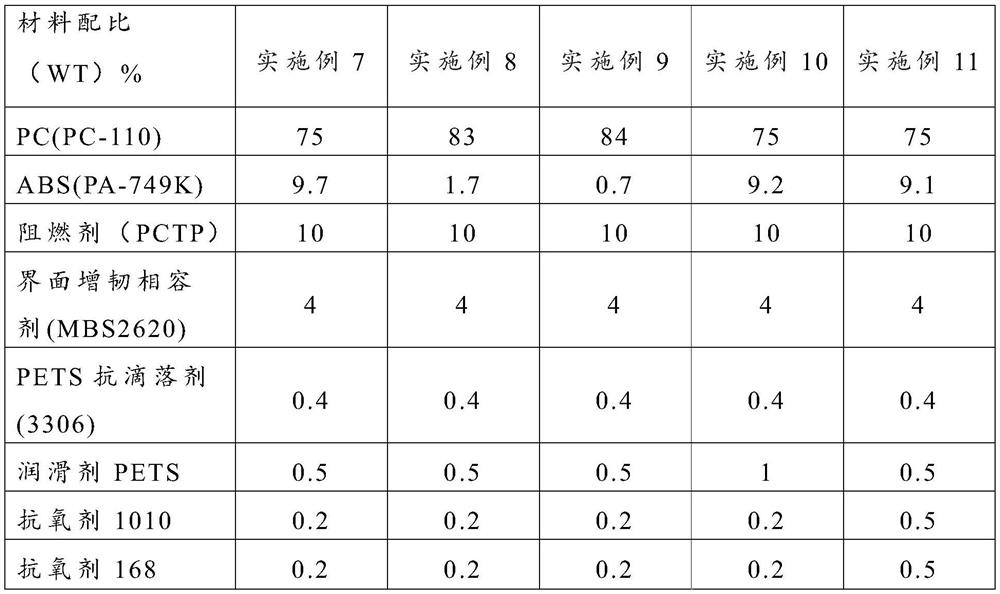

[0050] Based on the above tests and analysis, considering that the flame retardant synergist is also crucial for improving the flame retardancy and rigidity of the PC / ABS alloy, the applicant has further carried out the test, as described in Examples 12-17, the specific formula and The components are shown in Table 4.

[0051] Table 4 embodiment 12-17 component and formula

[0052]

[0053] According to the proportioning of Table 4, prepare material according to the following method:

[0054] 1) Mix PC, ABS, and a high-speed mixer for 3 minutes, then add flame retardant, interface toughening compatibilizer, flame retardant synergist, PTFE anti-dripping agent, lubricant and antioxidant and mix for 5 minutes;

[0055] 2) Add the mixture obtained in step 2) to a co-rotating twin-screw extruder to extrude and granulate. pellets into plastic pellets.

[0056] The produced materials were tested for tensile strength, bending strength, impact strength, flame retardancy and other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com