Oil-water bentonite polyurea composite lubricating grease composition and preparation method thereof

A grease composition, a technology of bentonite grease, applied in the field of grease, can solve the problems of low consistency, service temperature, poor lubricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example ---

[0105] Preparation example---Preparation of polyurea grease

[0106] 400g PAO4 lubricating base oil (100 ℃ kinematic viscosity is 4mm 2 / s) Stir and heat up to 52-55°C, add 33g of octadecylamine and 12g of cyclohexylamine during this period, stir for 30min, add 34g of diphenylmethane diisocyanate at 70-80°C for 30min, continue to heat up to 205°C Stop heating, keep warm for 15 minutes, pour 150g of PAO4, after cooling down to 130°C, add 4g of extreme pressure anti-wear agent and 1g of rust inhibitor, stir for 30 minutes, grind and homogenize to obtain polyurea grease.

Embodiment 1

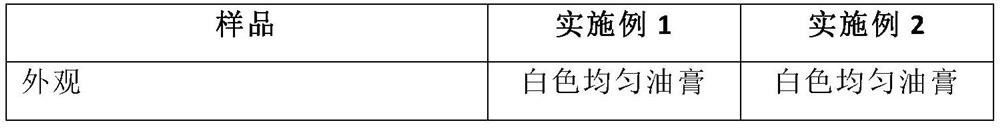

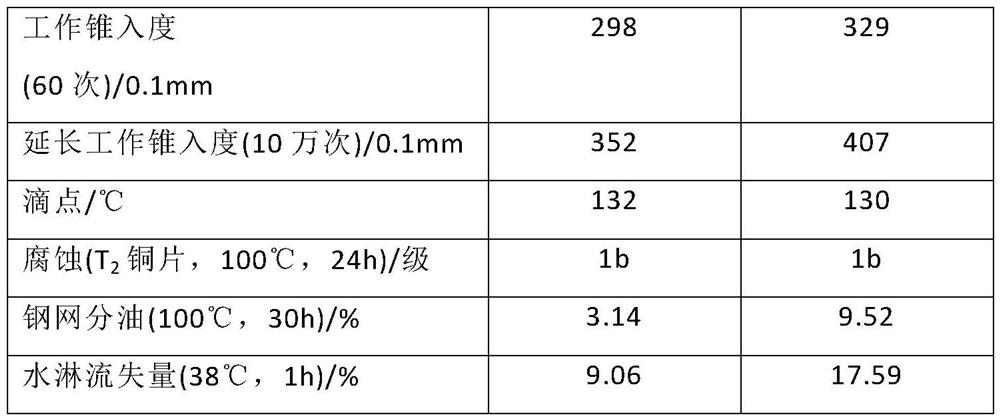

[0108] Add 4g of polyethylene glycol 2000 into 36g of water, keep the temperature at 20°C, stir thoroughly, and dissolve completely to obtain a mixed solution. Then 27g of organic amine-modified montmorillonite was added into the mixture, and stirred for 15 minutes. Then slowly add 3g of propylene carbonate in a trickle, fully stir for 30min, then add 30g of PAO4 lubricating base oil (the kinematic viscosity at 100°C is 4mm 2 / s), continue to heat up to 60°C, stir for 15 minutes, add 400g of polyurea grease after stirring evenly, grind and homogenize, and obtain oil-water type bentonite-polyurea composite grease. The physical and chemical properties of the obtained fat are shown in Table 1.

[0109] The dosage percentage of each component for preparing the oil-water type bentonite-polyurea composite grease is: polyethylene glycol: 0.8%; water: 7.2%; PAO 4: 6%; bentonite: 5.4%; propylene carbonate: 0.6%; Polyurea Grease: 80%.

Embodiment 2

[0111] Add 4g of polyethylene glycol 2000 into 36g of water, keep the temperature at 20°C, stir thoroughly, and dissolve completely to obtain a mixed solution. Then add 20 g of organic amine-modified montmorillonite into the mixture, and stir for 15 min. Then slowly add 5g of propylene carbonate in a trickle, fully stir for 30min, then add 35g of PAO4 lubricating base oil (the kinematic viscosity at 100°C is 4mm 2 / s), continue to heat up to 60°C, stir for 15 minutes, add 100 g of polyurea grease after stirring evenly, grind and homogenize, and obtain oil-water type bentonite-polyurea composite grease. The physical and chemical properties of the obtained fat are shown in Table 1.

[0112] The dosage percentage of each component for preparing the oil-water type bentonite-polyurea composite grease is: polyethylene glycol: 2%; water: 18%; PAO 4: 17.5%; bentonite: 10%; propylene carbonate: 2.5%; Polyurea Grease: 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com