Square channel cooling type scrap steel burdening port and manufacturing method thereof

A cooling type, channel technology, used in the manufacture of converters, etc., can solve problems such as poor performance and short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

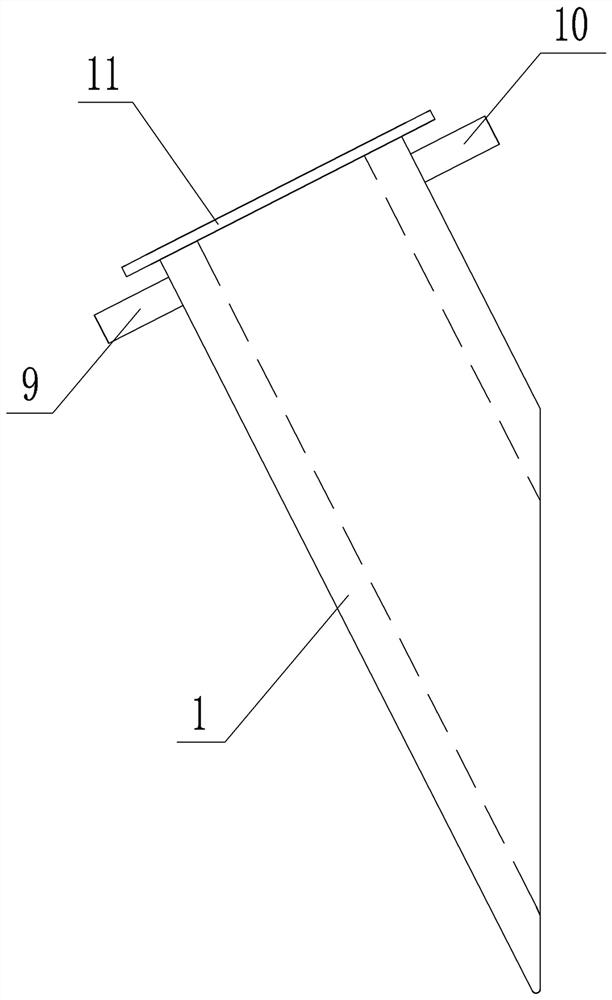

[0045] Example 1 Square channel cooling type scrap batching port

[0046] This example Figure 1 to Figure 9As shown, it is a square channel cooling type scrap steel batching port, which includes a cylinder body 1, which is an inclined hollow cylindrical structure with upper and lower openings fixed on the vaporization cooling flue of the converter. In this embodiment, the cross section of the cylinder body 1 is circular, and the cylinder body 1 is arranged on the side wall of the vaporization cooling flue and communicates with the vaporization cooling flue. Since the cylinder body 1 is the channel through which steel scrap enters the converter, there are high requirements for the wear resistance and impact resistance of the cylinder body 1 .

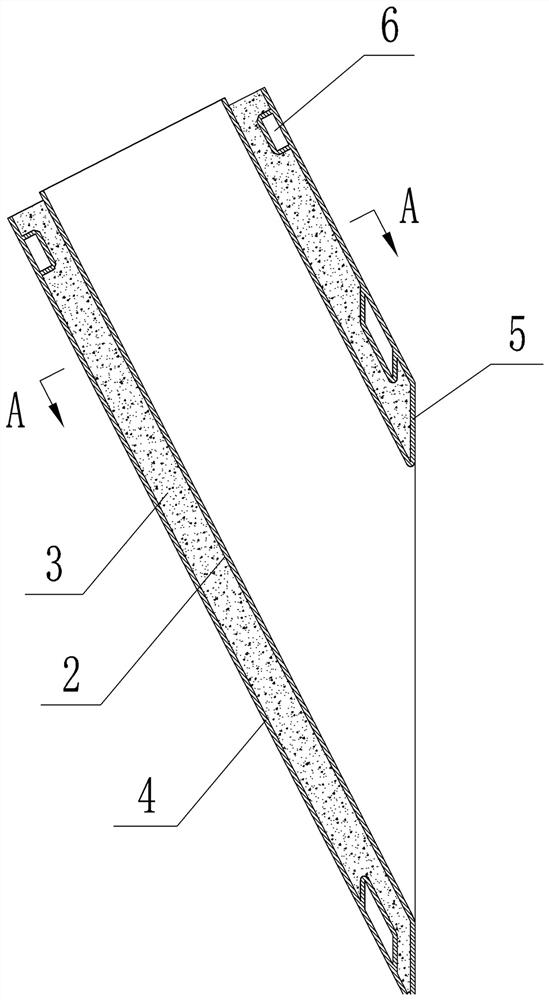

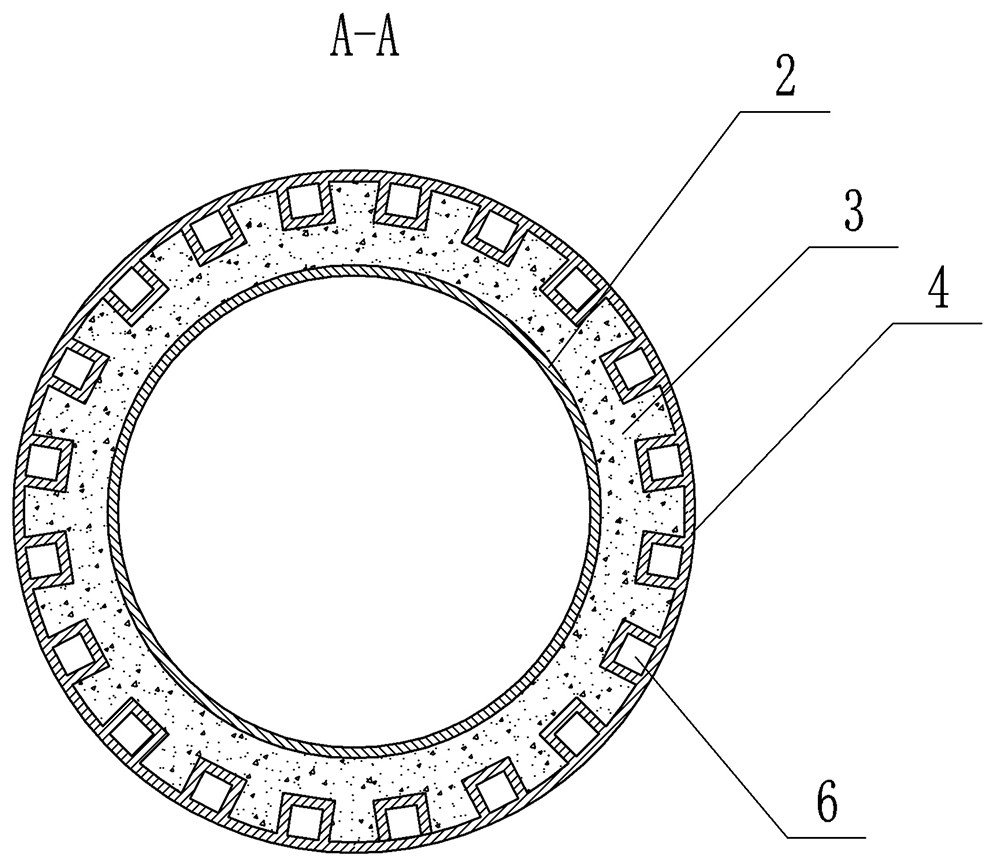

[0047] Since the cylinder 1 is a hollow structure, the cylinder 1 has a cylinder wall. In order to improve the wear resistance and impact resistance of the cylinder 1, the cylinder wall is set into a multi-layer structure: as figure ...

Embodiment 2

[0056] Example 2 Square channel cooling type scrap batching port

[0057] The structure of this embodiment is basically the same as that of Embodiment 1, the difference lies in the arrangement of the cooling circulation channels 6 . Such as Figure 9 As shown (the direction of the arrow in the figure is the flow direction of the cooling liquid), the cooling circulation channels 6 in this embodiment are arranged in parallel. The cooling circulation passages 6 arranged in parallel include vertical passages 61 arranged along the height direction of the cylinder wall, and transverse passages 62 connecting the vertical passages 61 head to head and tail to tail. The water inlet 7 and the water outlet 8 are both Opened on the transverse passage 62. In order to make the cooling cycle more sufficient, the water inlet 7 and the water outlet 8 are arranged on the transverse channels 62 on opposite sides of the cylinder 1 . Wherein, the sidewalls of the vertical passages 61 on both sid...

Embodiment 3

[0058] Example 3 Method for making a square channel cooling type scrap steel batching port

[0059] This embodiment is a manufacturing method of a square channel cooling type scrap steel batching port, which is used to make the square channel cooling type scrap steel batching port in Embodiment 1 or Example 2. The manufacturing method of the square channel cooling type scrap steel batching port in the present embodiment comprises the following steps carried out successively:

[0060] Making the cavity: take the low-temperature cooling layer 4, enclose the cooling circulation channel 6 on the inner wall of the low-temperature cooling layer 4, take the temperature-resistant layer 2 and the lower sealing plate 5, and connect the temperature-resistant layer 2 and the low-temperature cooling layer through the lower sealing plate 5 4. The ends near the vaporization cooling flue are connected and sealed to form a cavity. At this time, a cooling circulation channel 6 is formed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com