Fabric with excellent performance and application of fabric in field of clothes

A kind of fabric and excellent technology, applied in the field of clothing, can solve the problems of weak affinity between natural dyes and Lyell fibers, low dyeing rate, poor reactivity, etc., and achieve the effect of smooth hand feeling, natural luster, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] As a kind of preferred technical scheme, the preparation method of described modified lyocell fiber and modified cotton fiber comprises the steps:

[0023] 1) The lyocell fiber and cotton fiber are processed through opening, impurity removal and carding;

[0024] 2) Prepare a modification solution, immerse the treated lyocell fiber and cotton fiber in the modification solution, wash and dry with clean water after immersion, the immersion time is 2-3h, and the temperature is 30-40°C.

[0025] As a preferred technical solution, the modification solution in step 2) is an amino polysiloxane solution, and the methyl siloxane is mixed with the catalyst, the reaction temperature is 120°C, and the reaction time is 1.5h. A coupling agent was added under vacuum to continue the reaction, and an end-capping agent was added in the later stage of the reaction to prepare an aminopolysiloxane solution. The reaction time was 4 hours, and the reaction pressure was 0.02 MPa.

[0026] The...

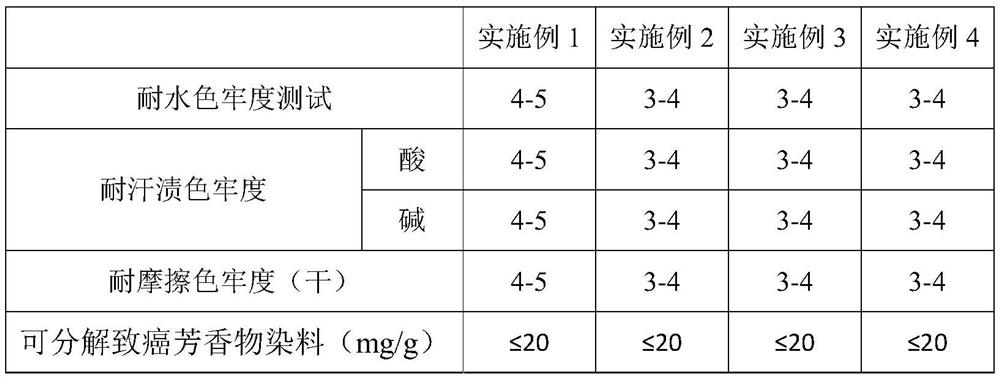

Embodiment 1

[0038] A fabric with excellent performance. The raw materials include lyocell fiber and cotton fiber. Combined with the established percentage of moisture regain, the proportion of lyocell fiber is 68%, and the proportion of cotton fiber is 32%.

[0039] The lyocell fiber is a modified lyocell fiber, the cotton fiber is a modified cotton fiber, and the fabric is prepared by blending the modified lyocell fiber and the modified cotton fiber.

[0040] The preparation method of described modified lyocell fiber and modified cotton fiber comprises the steps:

[0041] 1) The lyocell fiber and cotton fiber are processed through opening, impurity removal and carding;

[0042] 2) Prepare the modification solution, immerse the treated lyocell fiber and cotton fiber in the modification solution, wash and dry with clean water after immersion, the immersion time is 2.5h, and the temperature is 35°C.

[0043] The modification solution in the step 2) is a cationic amphiphilic aminopolysiloxa...

Embodiment 2

[0056] A fabric with excellent performance. The raw materials include lyocell fiber and cotton fiber. Combined with the established percentage of moisture regain, the proportion of lyocell fiber is 68%, and the proportion of cotton fiber is 32%.

[0057] The lyocell fiber is a modified lyocell fiber, the cotton fiber is a modified cotton fiber, and the fabric is prepared by blending the modified lyocell fiber and the modified cotton fiber.

[0058] The preparation method of described modified lyocell fiber and modified cotton fiber comprises the steps:

[0059] 1) The lyocell fiber and cotton fiber are processed through opening, impurity removal and carding;

[0060] 2) Prepare the modification solution, immerse the treated lyocell fiber and cotton fiber in the modification solution, wash and dry with clean water after immersion, the immersion time is 2.5h, and the temperature is 35°C.

[0061] The modification solution in the step 2) is an aminopolysiloxane solution.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com