Cold/heat storage and supply cascade phase change capillary network radiation wall tail end device

A technology of capillary network and terminal device, which is applied in space heating and ventilation details, heat storage equipment, household heating, etc., can solve the complex preparation process of double-effect phase change plates, difficult melting/solidification, and inability to achieve fast speed, etc. problem, achieve the effect of reducing mechanical cooling capacity, overcoming unstable supply, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and examples.

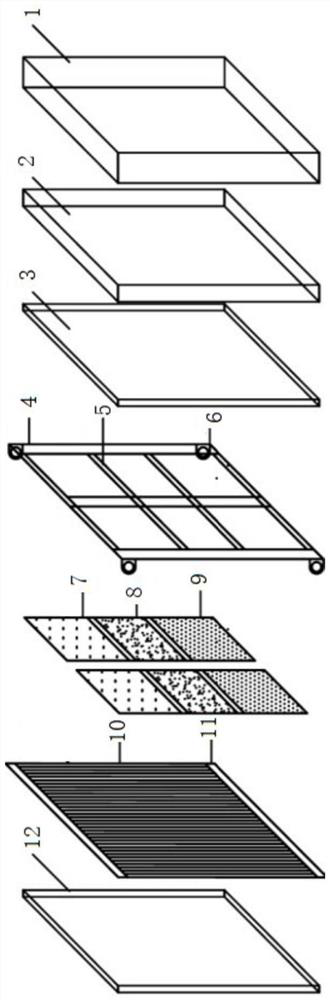

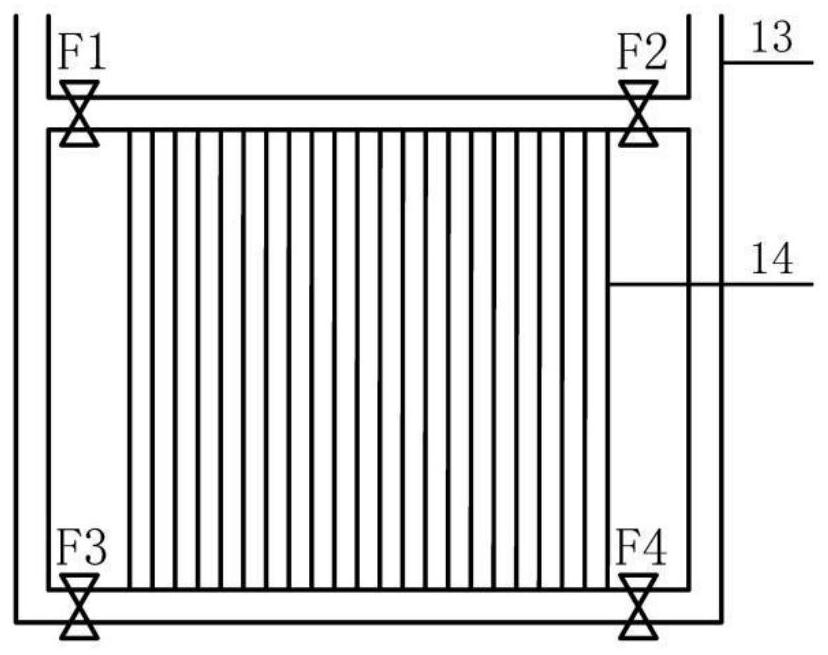

[0020]Such asfigure 1 As shown, the structure of the end device of the radiation / thermal tube mesh radiation wall of the present invention is described. The apparatus includes a base layer wall 1, an insulating insulation layer 2, a moisture-proof layer 3, a light bone 4 made from a light steel kemberne, a cover keel 5; including the first stage phase change material 8, the second phase change material 9 and The third stage phase change material 10 constitutes a layer of step phase change material; the capillary dry tube 10, the capillary branch tube 11, and the decorative layer 12. Light steel keel is used to fix cassette material layers and capillary webs. The phase change temperature of the first stage phase change material layer 7 is about 28 ° C, the phase change temperature of the second stage phase change material layer 8 is about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com