Preparation method of acid-binding functional catalyst for synthesizing methyltris(methylethylketoxime)silane

A technology of methyl tributyl ketone oxime and base silane, which is applied in the field of preparation of acid-binding functional catalysts, and can solve problems such as limiting production capacity, increasing production costs, and large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

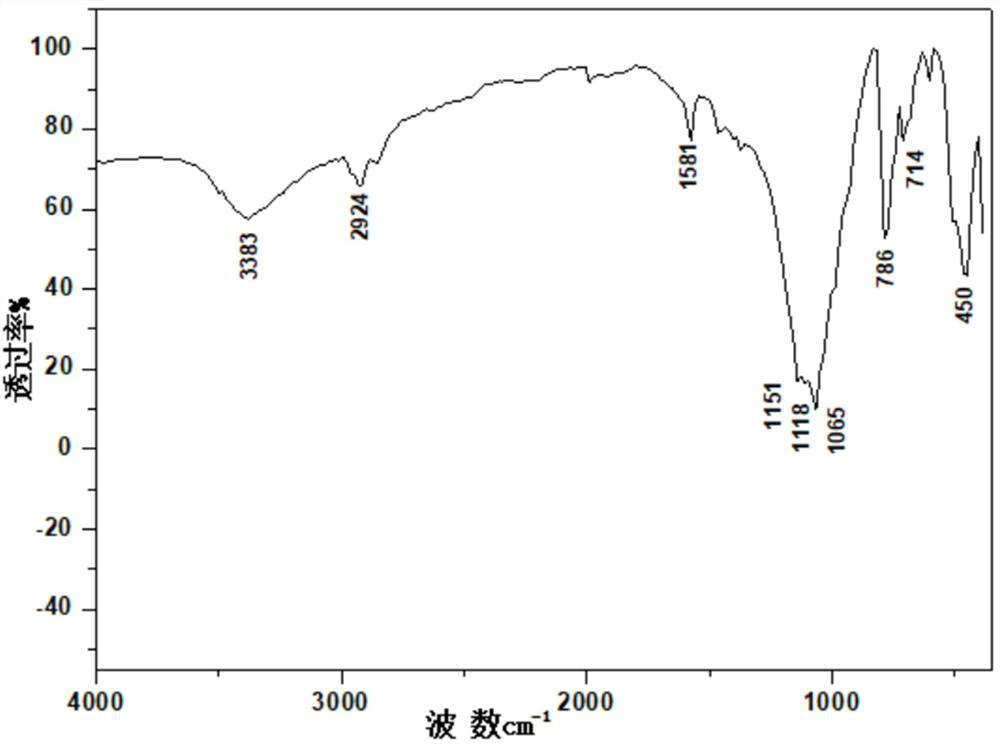

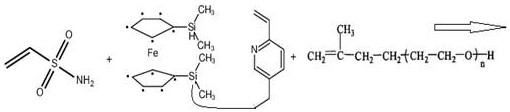

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of the acid-binding functional catalyst that is used for synthesizing methyl tributylketoxime base silane, its operating steps are:

[0030] Step 1: Add 80g of activated mesoporous solid powder and 400g of toluene into the reactor, stir and disperse evenly, then heat up to 90°C, then add 5g of 2,5-divinyl-pyridine into the reactor, stir and mix 30min, then 3g of 1,1`-bis(dimethylsilyl)iron, 0.1g of isopropanol solution of chloroplatinic acid with a mass percent content of 5-10%, were evenly added into the reaction kettle slowly , then control the temperature to 60°C, stir the reaction for 1h,

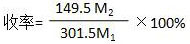

[0031] Step 2: Add 8g of vinyl sulfonamide, 1.2g of allyl polyoxyethylene ether, 0.5g of benzoyl peroxide, then control the temperature to 80°C, stir and react for 10h, and filter after completing the reaction to obtain a solid Slurry and purify with absolute ethanol for three times, and then vacuum dry to obtain the acid-binding functional catalyst ...

Embodiment 2

[0035] A kind of preparation method of the acid-binding functional catalyst that is used for synthesizing methyl tributylketoxime base silane, its operating steps are:

[0036] Step 1: Add 90g of activated mesoporous solid powder and 460g of toluene into the reactor, stir and disperse evenly, then heat up to 100°C, then add 7g of 2,5-divinyl-pyridine into the reactor, stir and mix 40min, then 5g of 1,1'-bis(dimethylsilyl)iron, 0.3g of 7% isopropanol solution of chloroplatinic acid by mass percent, evenly and slowly added to the reactor, and then Control the temperature to 604°C, stir and react for 1.5h,

[0037] Step 2: Add 11g of vinyl sulfonamide, 2.5g of allyl polyoxyethylene ether, 0.9g of benzoyl peroxide, then control the temperature to 90°C, stir for 17 hours, and filter after the reaction to obtain a solid Slurry and purify with absolute ethanol for 4 times, and then vacuum dry to obtain the acid-binding functional catalyst for synthesizing methyltributanoximinosilane...

Embodiment 3

[0041] A kind of preparation method of the acid-binding functional catalyst that is used for synthesizing methyl tributylketoxime base silane, its operating steps are:

[0042] Step 1: Add 140g of activated mesoporous solid powder and 500g of toluene into the reactor, stir and disperse evenly, then heat up to 110°C, then add 15g of 2,5-divinyl-pyridine into the reactor, stir and mix 60min, then 6g of 1,1'-bis(dimethylsilyl)iron, 0.5g of 10% isopropanol solution of chloroplatinic acid in mass percentage, evenly and slowly added to the reactor, and then Control the temperature to 67°C, stir the reaction for 3h,

[0043] Step 2: Add 12g of vinyl sulfonamide, 3.5g of allyl polyoxyethylene ether, 1.5g of benzoyl peroxide, then control the temperature to 100°C, stir and react for 20h, filter after the reaction is completed, and obtain the solid Slurry and purify with absolute ethanol for 5 times, and then vacuum-dry to obtain the acid-binding functional catalyst for synthesizing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com